Conveyor system comprising a friction coefficient measuring device

A technology for coefficient of friction, measuring equipment, applied in the field of conveyors and lubrication systems, which can solve problems such as disturbing normal "transportation" and reducing throughput time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

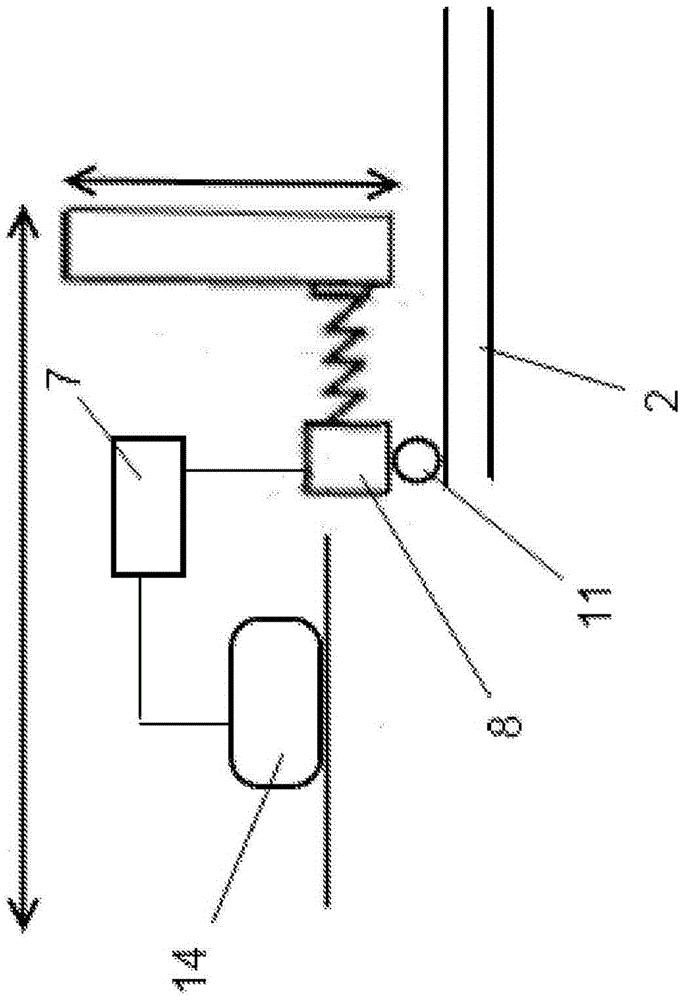

[0075] Note that the invention will be described with reference to the example of a conveyor and a lubrication system, but it is to be noted that the invention can also be used in a conveyor system without a lubricant spreading device. In such a conveyor system, the control means are arranged for providing a further signal dependent on a signal representing the measured quantity proportional to the coefficient of friction provided by the friction measuring device. When the measured quantity, which is proportional to the coefficient of friction, exceeds a threshold value, a further signal is generated by the control device, which can be used, for example, as an indication that the conveyor surface needs to be cleaned.

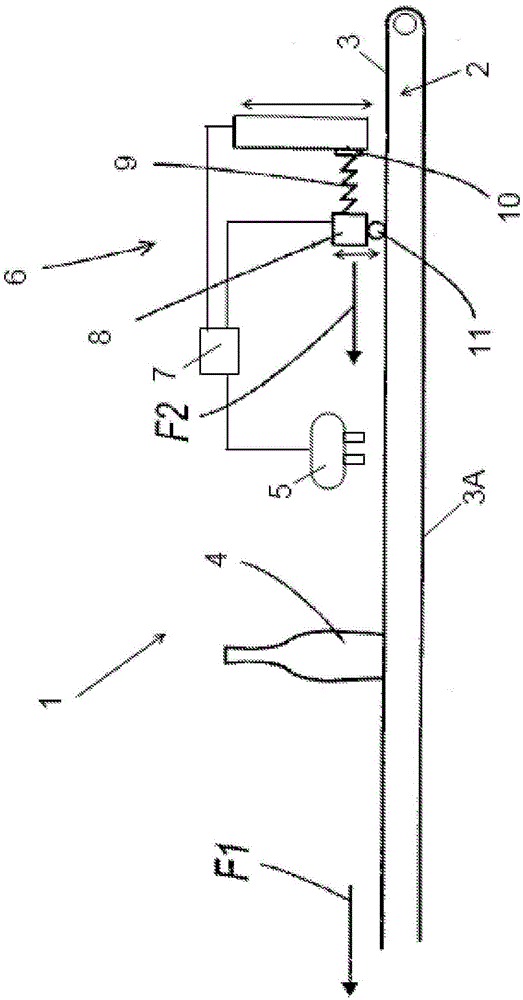

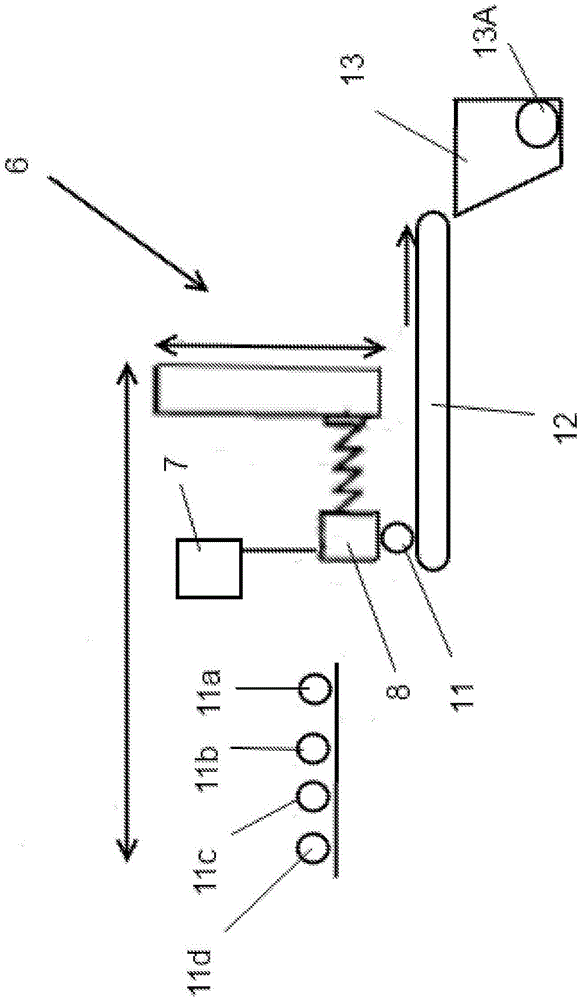

[0076] exist figure 1 An embodiment of a conveyor and lubrication system according to the invention is schematically shown in . The system 1 comprises an endless conveyor 2 having an upper conveyor surface 3 on which items 4, in this example bottles, are transp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com