A powder discharge device for a milk maker

A technology of milk brewing machine and discharging part, which is applied to beverage preparation devices, kitchen utensils, household utensils, etc., can solve the problems of lack of sealing at the output end, long transmission displacement, moisture in milk powder, etc., and achieve high food safety and simplified structure. , to avoid the effect of moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

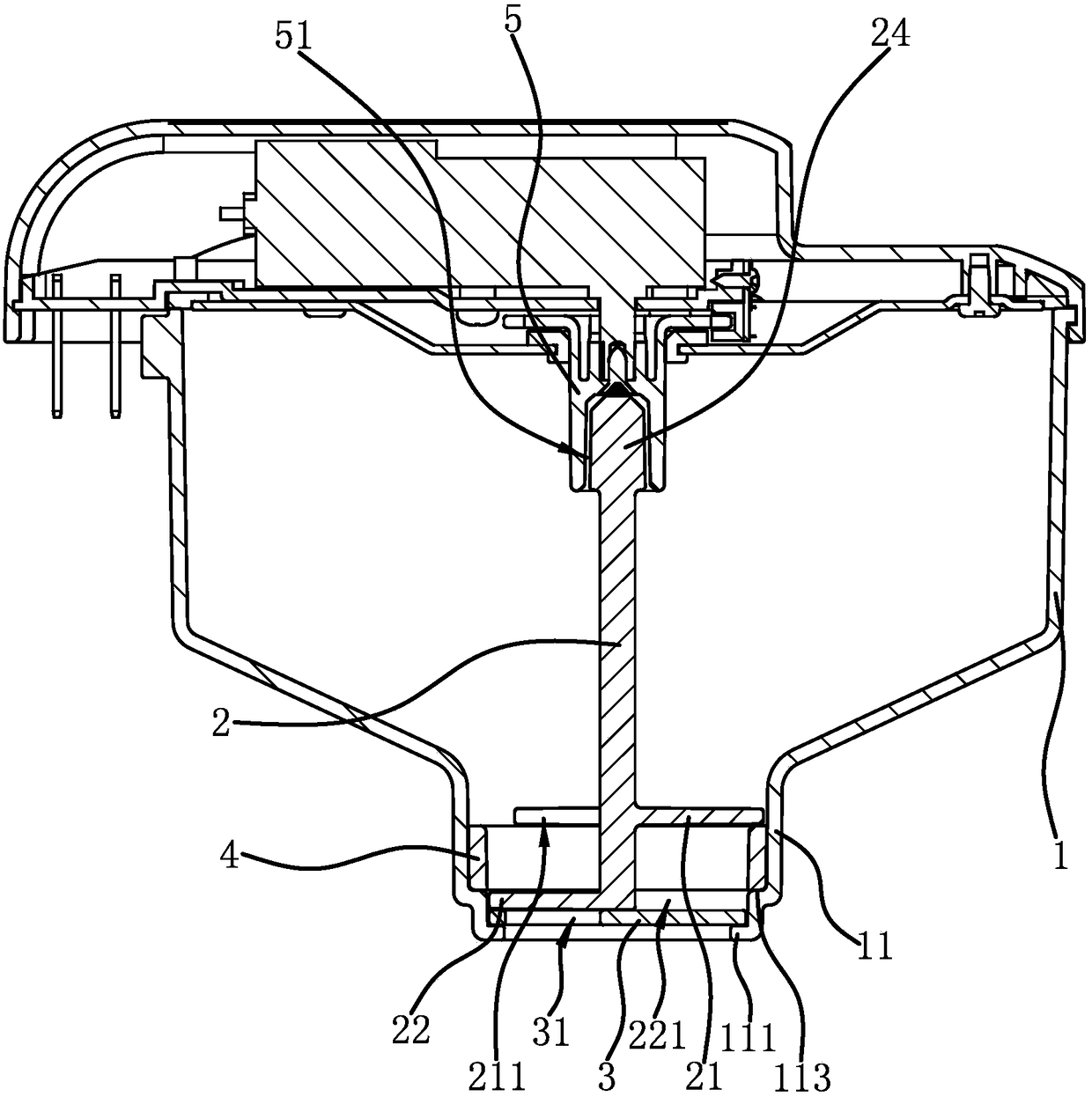

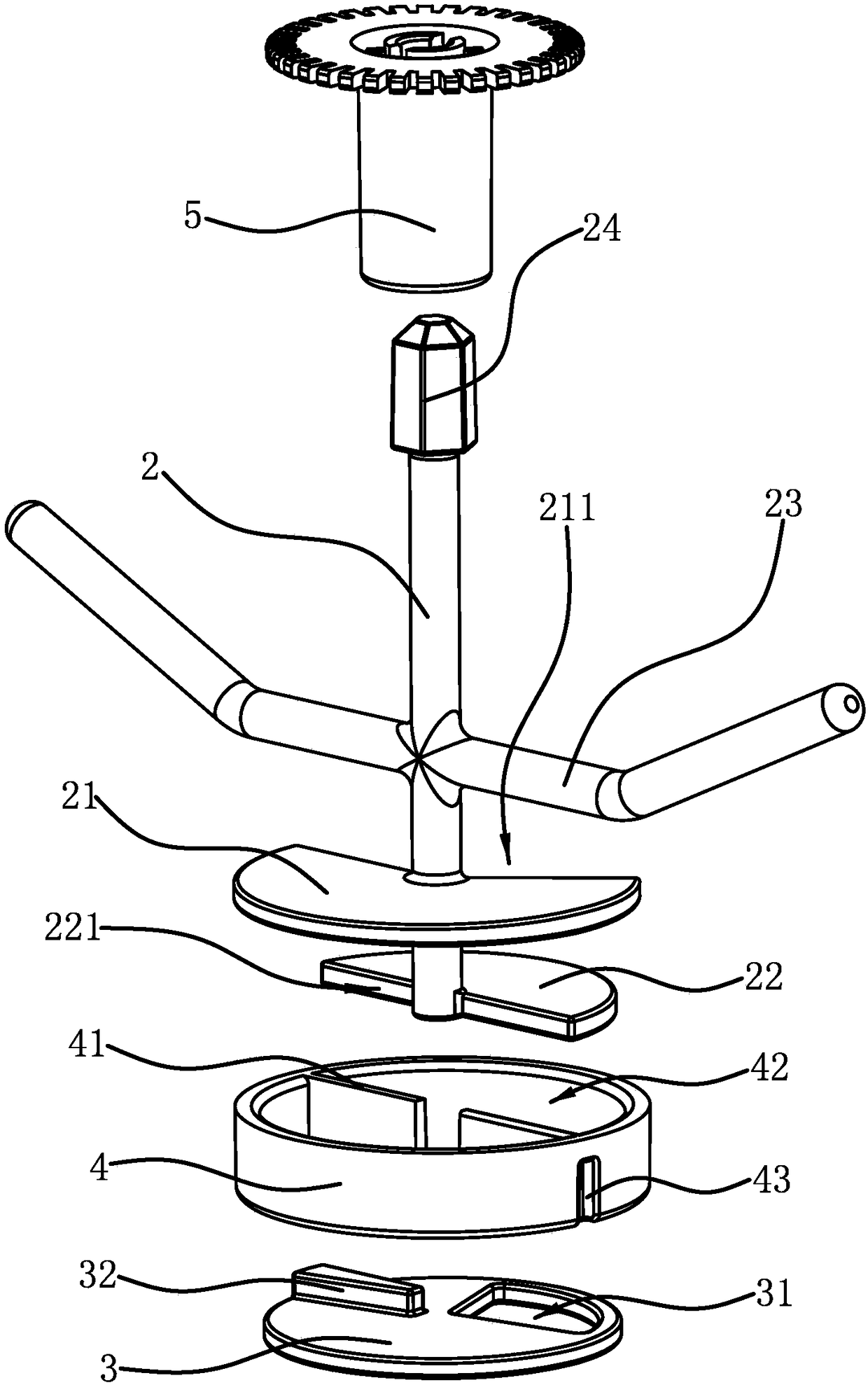

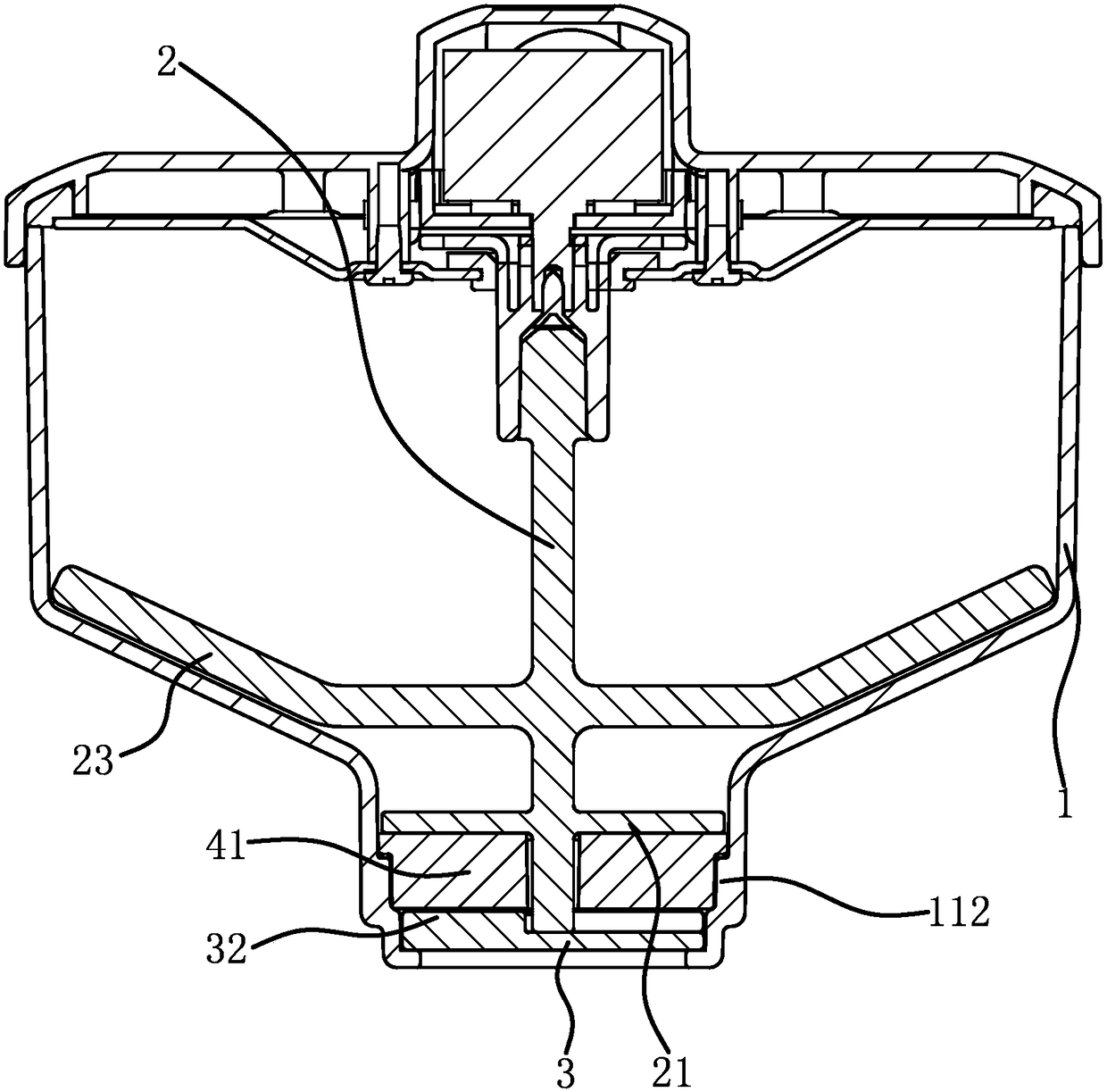

[0028] like figure 1 , figure 2As shown, a powder discharge device of a milk machine includes a main shaft 2 and a funnel-shaped material barrel 1, the material barrel 1 is vertically arranged, and the end of the material barrel 1 with a smaller opening faces downward, and the main shaft 2 is driven by a servo motor , the upper cover is hinged on the casing, the servo motor is installed on the upper cover, and can move with the opening and closing of the upper cover. Of course, the output shaft of the servo motor is detachably connected with the upper end of the main shaft 2, and there is a The funnel-shaped mounting seat, the barrel 1 is placed in the mounting seat, when the upper cover is opened, the output shaft of the servo motor is separated from the upper end of the main shaft 2, and the barrel 1 can be taken out from the casing. The lower end of the barrel 1 has a discharge portion 11 that is straight and communicates with the opening of the lower end of the barrel 1....

Embodiment 2

[0033] The structure of the powder discharge device of this milk machine is basically the same as that of Embodiment 1, the difference is that Figure 4 As shown, the transmission member includes an arc-shaped groove 33 on the upper side of the cover plate 3, and the arc-shaped groove 33 is arranged concentrically with the main shaft 2, and a transmission pin 222 is provided on the lower side of the lower scraper 22. The transmission pin 222 Slidingly inserted in the arc groove 33, the central angle corresponding to the arc groove 33 is the angle required for the lower scraper 22 to completely break away from the discharge gap 31. When the discharge gap 31 is opened, the transmission pin 222 acts on the One end of the arc-shaped slot 33 acts on the other end of the arc-shaped slot 33 when closed.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap