an air jet loom

An air-jet loom and frame technology, which is applied in looms, textiles, textiles and paper making, etc., can solve the problem of low assembly accuracy of the main wallboard and the warp wallboard, affecting the service life of the beating shaft and the balance of the beating mechanism. It can save installation space, simple structure and heavy weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0030] An air-jet loom comprises a frame, a warp let-off mechanism, a shedding mechanism, a weft insertion mechanism, a weft beating mechanism, a coiling mechanism, a warp loosening mechanism and a pneumatic folding mechanism; wherein, the frame includes a wallboard, a support and middle bracket.

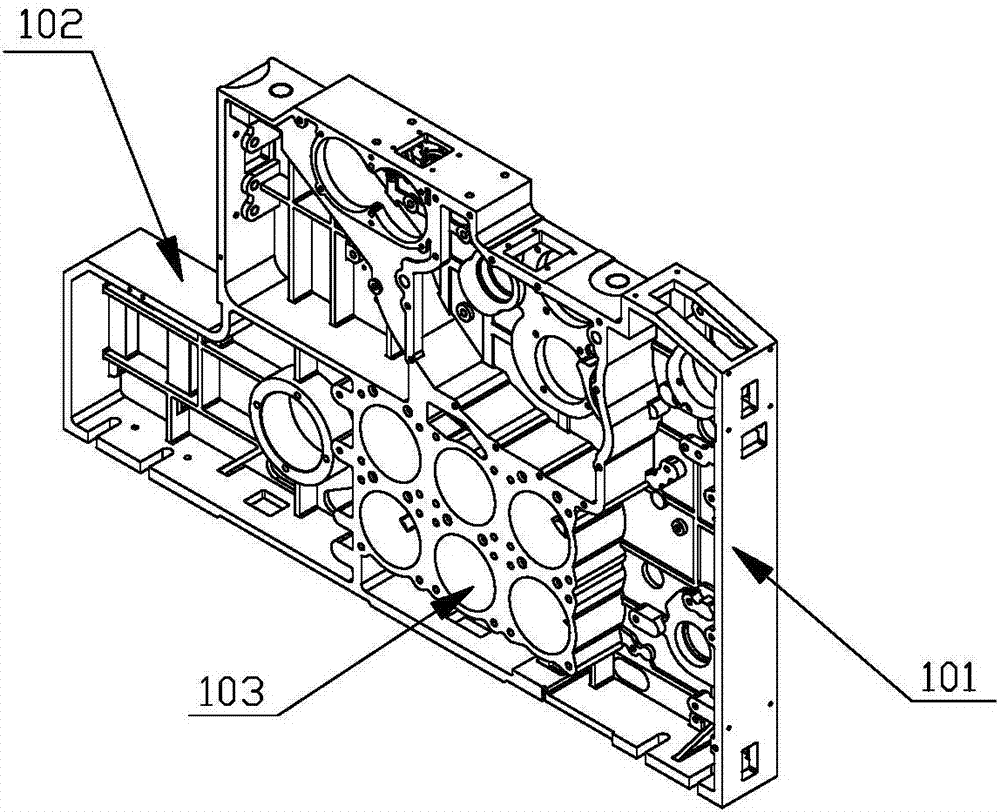

[0031] Such as figure 1 As shown, the wall panels include a main wall panel 101 and a let-off wall panel 102;

[0032] Through the above design, it is beneficial to ensure the integrity and stability of the air-jet loom wall panel, and saves the trouble of assembly.

[0033] Specifically, the main wallboard 101 and the warp let-off wallboard 102 are connected as a whole through a casting process, which is convenient for processing.

[0034] In addition, several air bag inner cavities 103 are provided on the main wall board 101 , the air bag inner c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com