Roller washing machine dewatering control method based on eccentricity judgment of 3D displacement sensor

A technology of displacement sensor and drum washing machine, which is applied in the control device of washing machine, washing device, textile and paper making, etc. It can solve the impact of vibration, noise, safety and life of washing machine, and can not test the vibration of the outer tub and the whole machine in real time and accurately Conditions, unsatisfactory dehydration effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

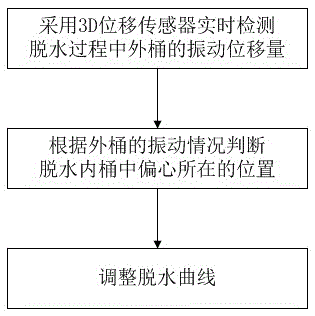

[0087] Such as figure 1 As shown, a dehydration control method based on 3D displacement sensor to judge the eccentricity of the drum washing machine. The 3D displacement sensor installed on the outer tub is used to detect the vibration displacement of the outer tub in real time during the dehydration process, and the eccentricity of the dehydration inner tub is judged according to the vibration of the outer tub. position to adjust the dehydration curve.

[0088] Specifically, the steps in the following order are included:

[0089] (1) Start dehydration and adjust the clothes.

[0090] (2) Set the dehydration speed of the washing machine to 90rpm. When the dehydration speed reaches 90rpm, the A-profile (moment of inertia) of the clothes is weighed, and the eccentricity threshold of the clothes is determined according to the weight range of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com