Combined filter screen and compressor with same

A technology for compressors and compressor shells, which is applied in the field of compressors, and can solve the problems of heavy filtering burden on the filter screen and the inability of the filter screen to remove debris in time, so as to prolong the service life and reduce the filtering burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

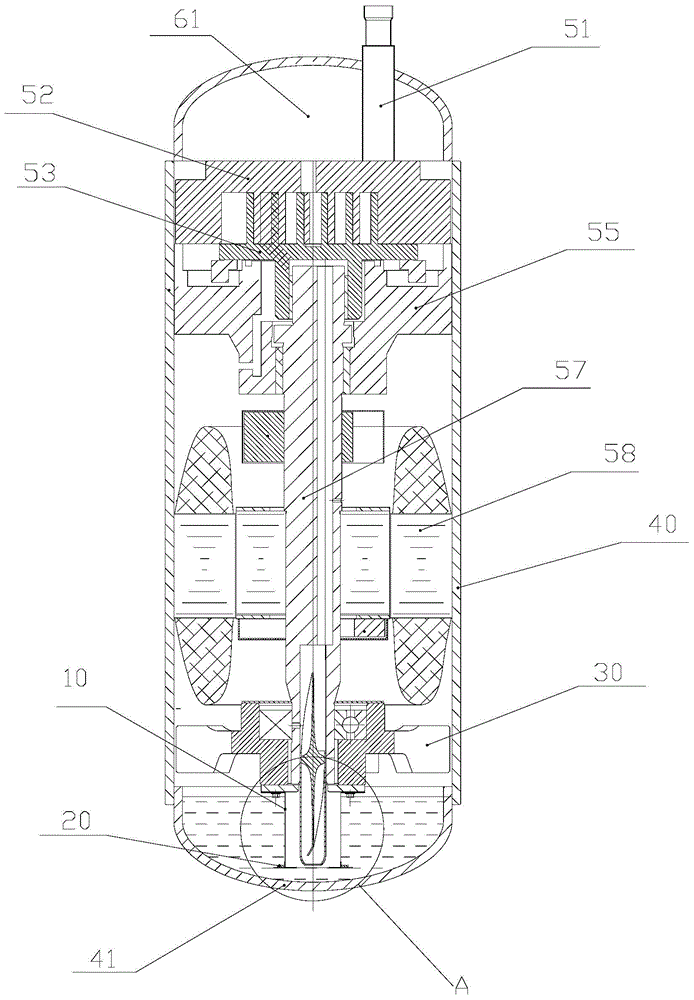

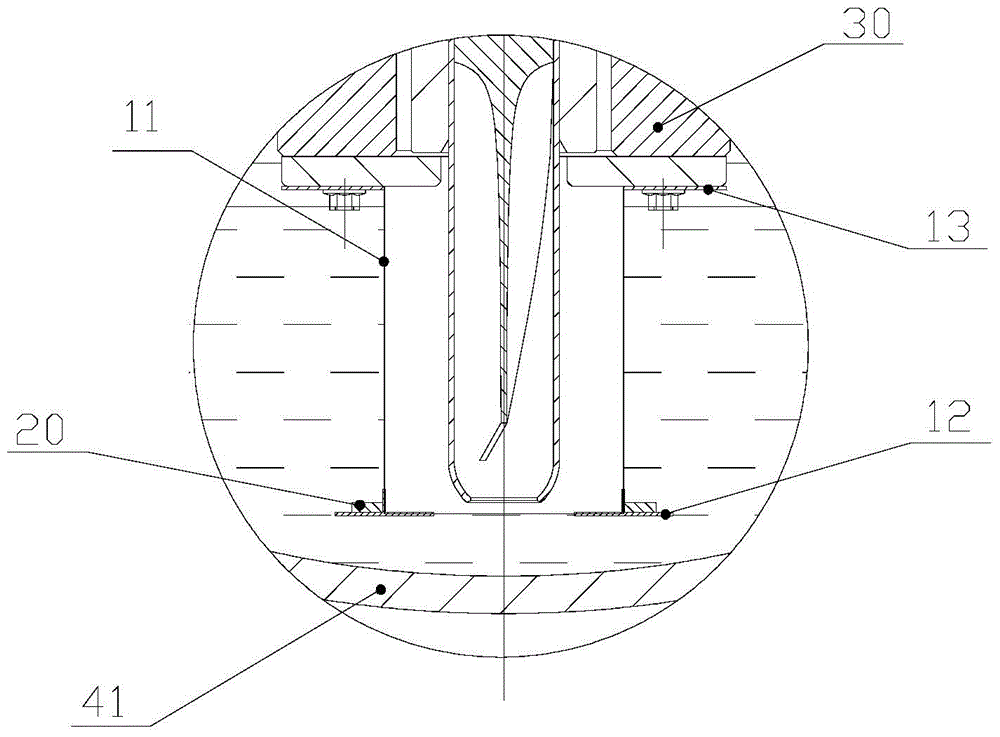

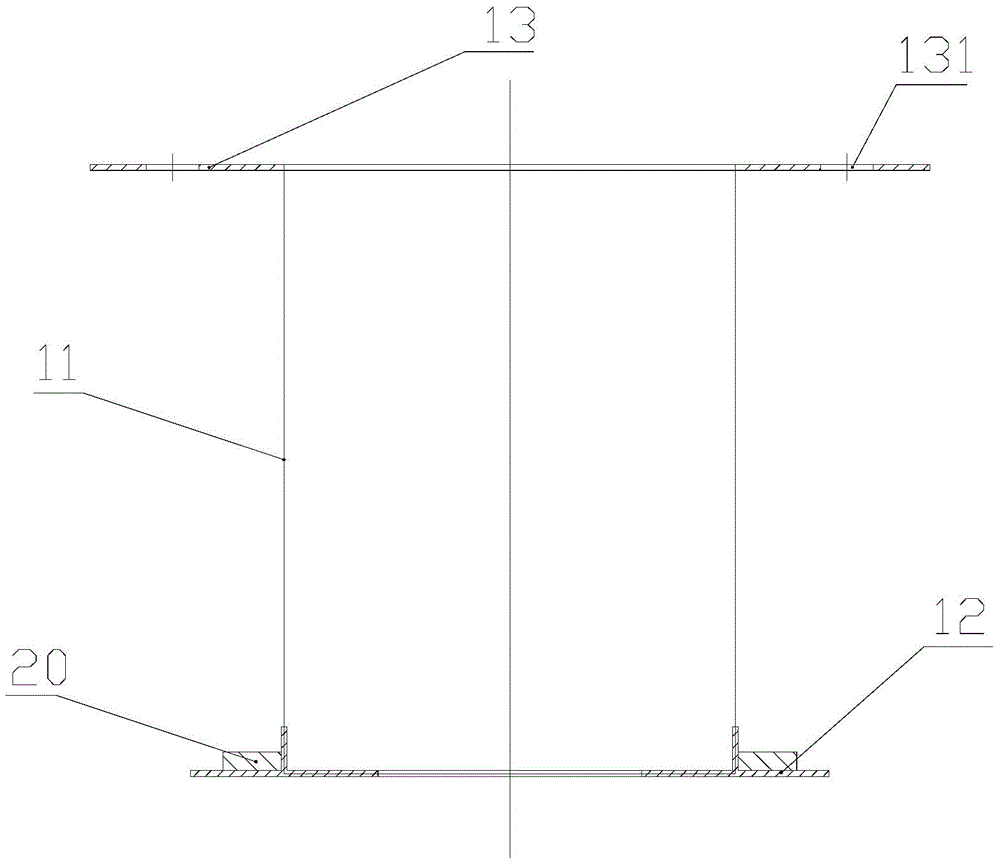

[0026] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

[0027] Such as Figures 1 to 7 As shown, according to an embodiment of the present invention, the combined filter screen includes a filter screen main body 10 and an impurity removal part 20, the filter screen main body 10 has a cylindrical section 11, the filter screen main body 10 is used for filtering oil, and the impurities in the oil are Debris is filtered, and impurity removal part 20 is fixedly arranged on the outer periphery of cylindrical section 11, and absorbs the debris filtered out by filter screen main body 10, and impurity removal part 20 is fixedly arranged on the outer periphery of cylindrical section 11 of filter screen main body 10, like this The impurities and debris filtered out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com