Mechanical water heater cold water automatic return device

An automatic backflow and water heater technology, applied in the direction of mechanical equipment, fluid heaters, lighting and heating equipment, etc., can solve the problems of system complexity, inconvenience, installation and use inconvenience, etc., and achieve broad application prospects, convenient use and operation, and installation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

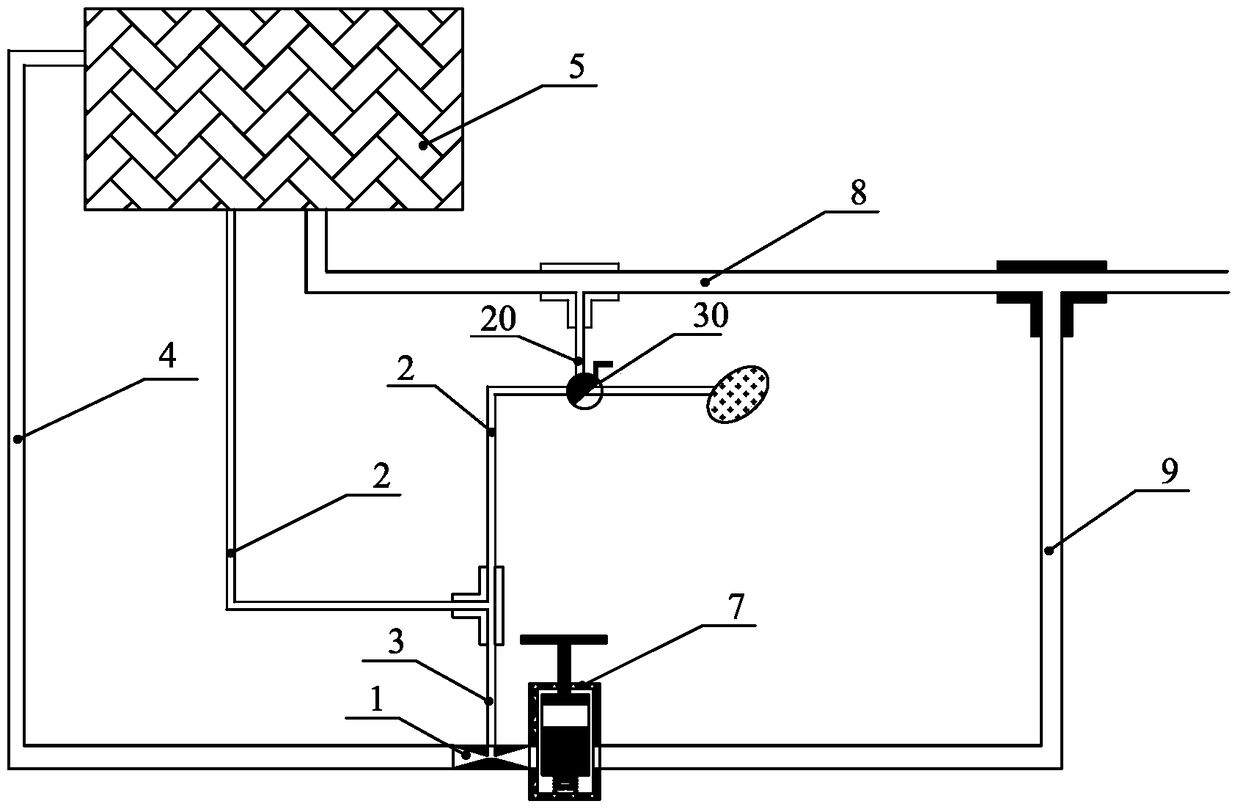

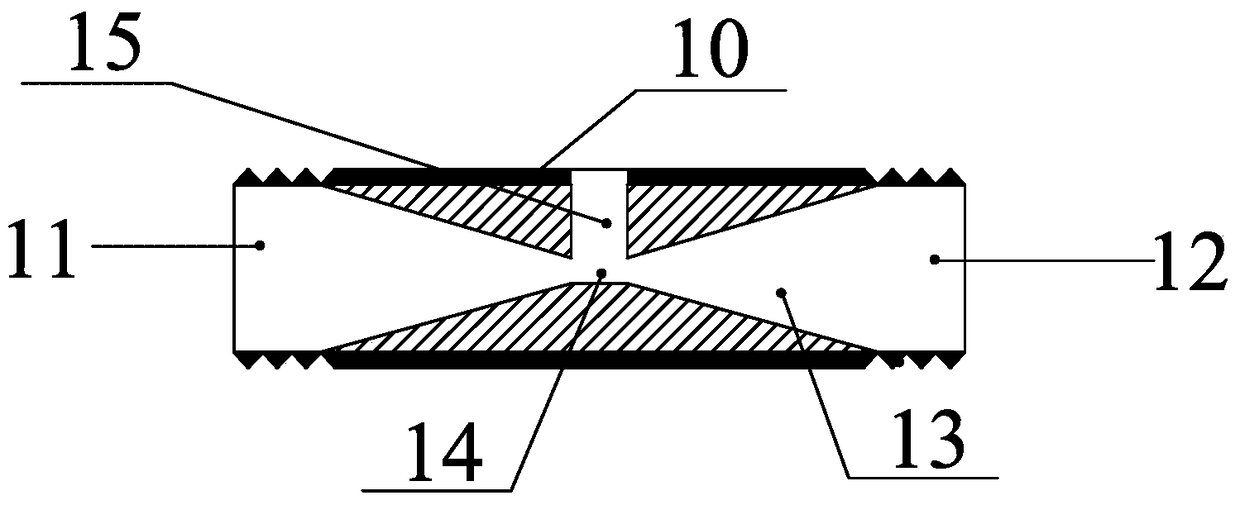

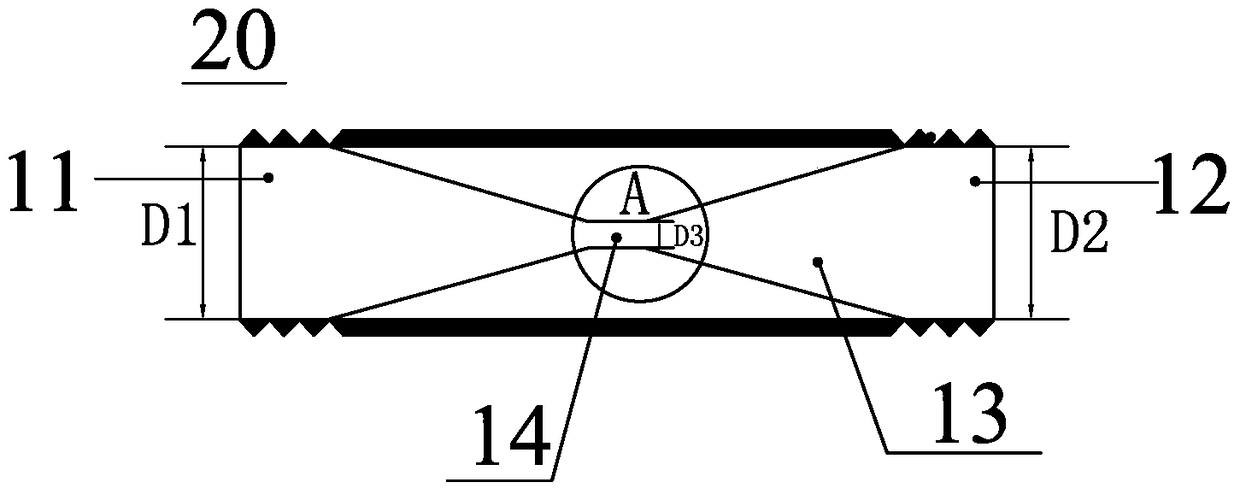

[0032] Such as figure 1 The mechanical water heater cold water automatic return device shown in has a water pump 1 (see figure 2 , 3 , 4), the water pump 1 includes a tubular body 10, the body 10 is hollow, the left and right ends are the water outlet 11 and the water inlet 12 respectively, and the hollow part of the body is used as the fluid channel 13. The cross-sectional area of the fluid channel 13 gradually decreases along the two ends of the body toward the middle, so the fluid channel 13 presents a shape with two ends wide and a middle narrow. In this embodiment, the fluid channel 13 is in the shape of two tapered tops facing each other and arranged symmetrically, similar to an hourglass, and the channel 14 between the two tapered tops is the narrowest part of the fluid channel 13, which is the cross-sectional area of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com