Optical detection apparatus

A technology of optical detection and equipment, applied in the field of optical detection, can solve problems such as limited operating table area, reduced operating space, dimness, etc., to achieve the effect of saving the area on the operating table and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

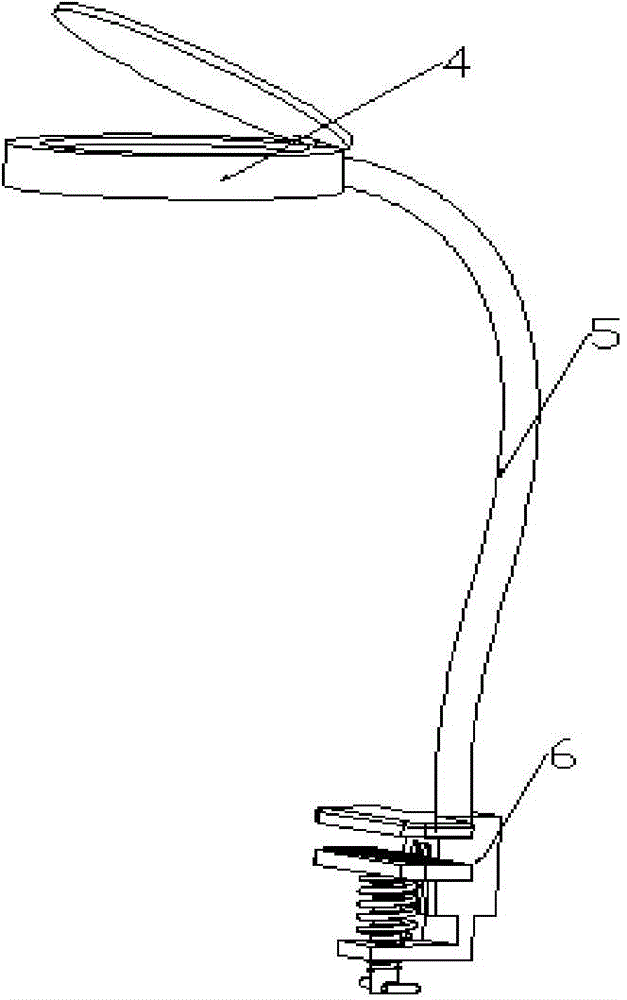

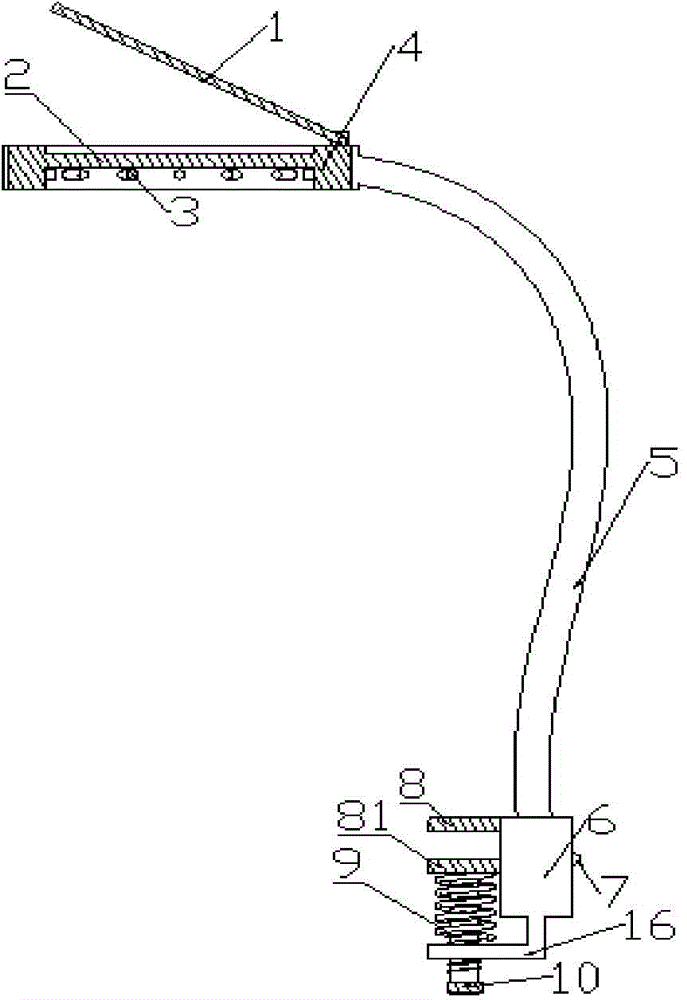

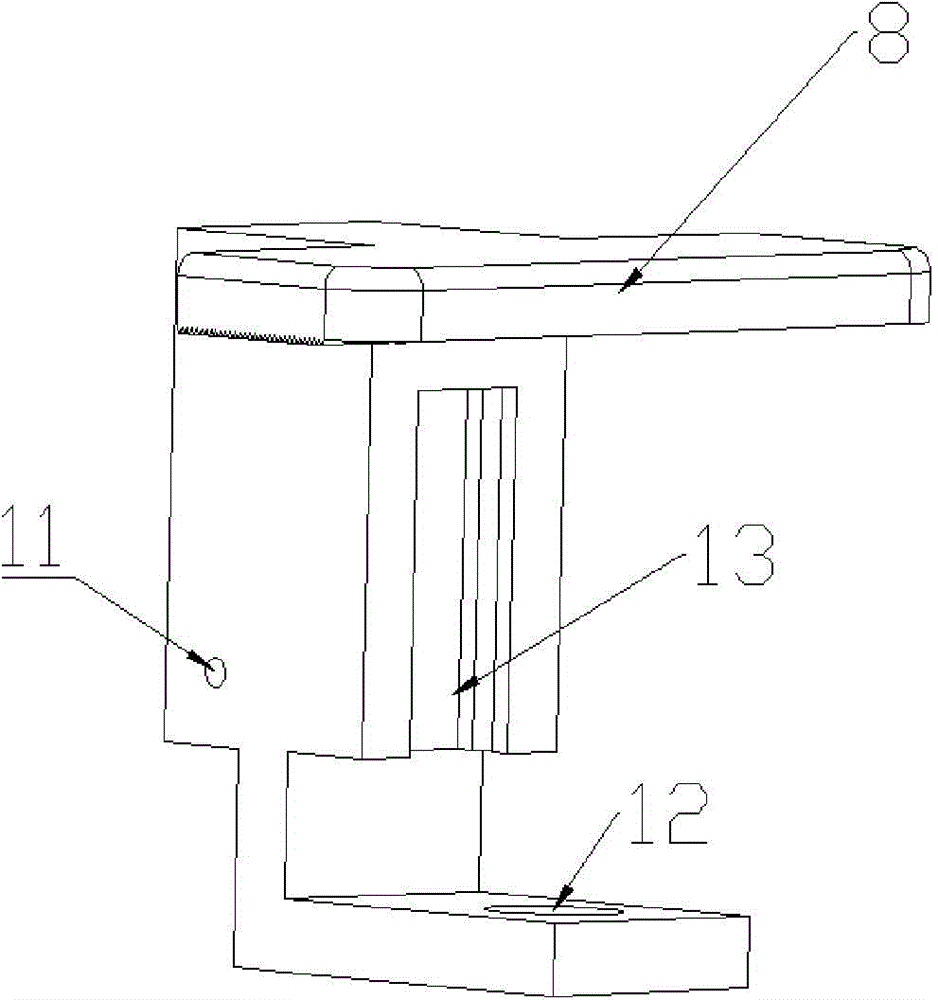

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, an optical detection device includes a magnifying glass main body 4, a shaping hose 5 and a fixed body 6, the magnifying glass main body 4 is provided with a magnifying glass 2, the magnifying glass main body 4 is connected with a shaping hose 5, and the shaping hose 5 is connected to the fixing body 6 The upper end of the fixed main body 6 is provided with a fixed upper plate 8, and the lower end of the fixed upper plate 8 is provided with a cross slide 13, and the cross slide 13 is provided with a fixed lower plate 81, and the lower end of the fixed main body 6 is provided with a fixed plate 16, and on the fixed plate 16 A fixing hole 12 is provided, and a fastening bolt 10 is worn on the fixing hole 12, and the fastening bolt 10 is pushed against the lower end of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com