Liquid crystal display device

A technology of liquid crystal display device and liquid crystal layer, which is applied in the directions of instruments, nonlinear optics, optics, etc., can solve problems such as cost increase, and achieve the effect of suppressing color shift and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

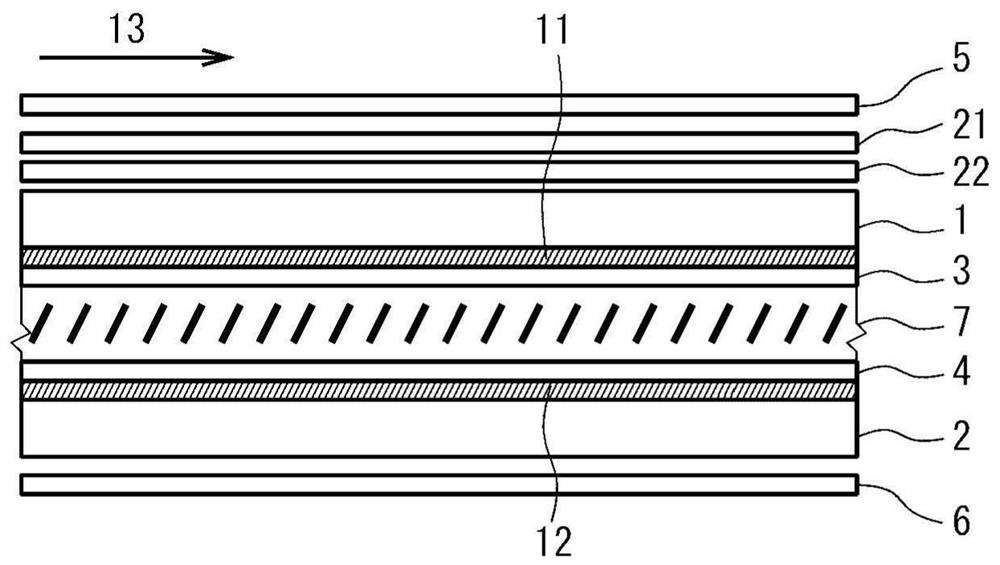

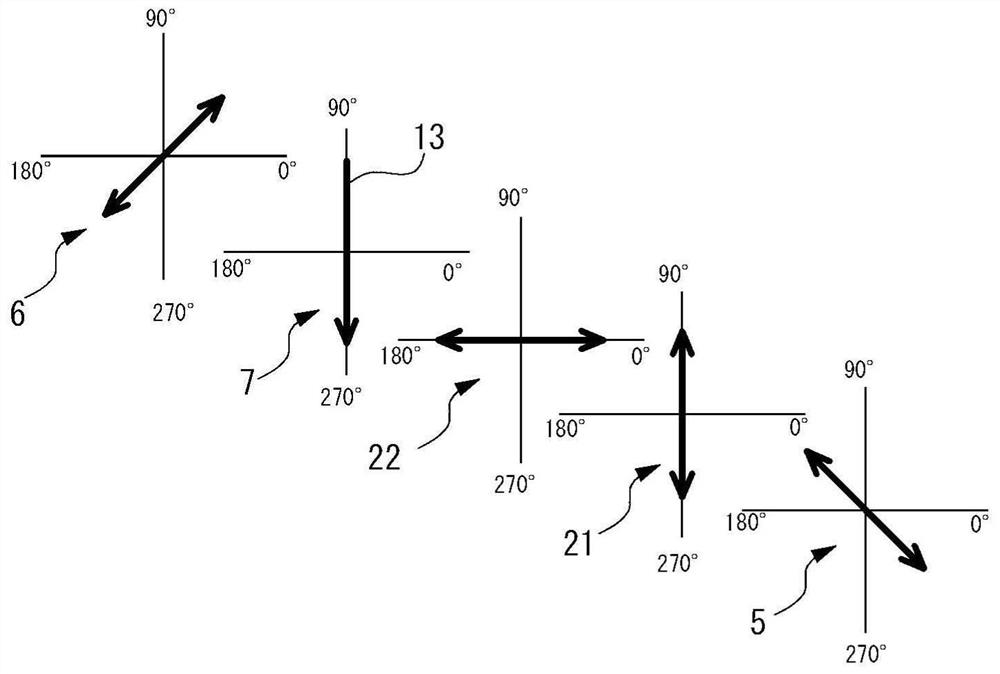

[0074] ・Structure of the liquid crystal display device: the structure of the first embodiment (see figure 1 and figure 2 )

[0075] ・First optical plate: An optical plate with an in-plane phase difference of 55 nm, a thickness direction phase difference of 220 nm, and negative biaxial optical anisotropy

[0076] ・Second optical plate: An optical plate with an in-plane retardation of 330 nm and positive uniaxial optical anisotropy

[0077] Figure 12(A) is a graph showing the calculation results of the spectroscopic spectrum of Example 1. As shown in the figure, in the liquid crystal display device of Example 1, when viewed from the front and when viewed at a polar angle of 50°, the following trend can be seen: Compared with the case of the above-mentioned comparative example, the transmittance on the short-wavelength side changes. The change in transmittance is small and the long-wavelength side is large. Among them, although the difference in transmittance between spect...

Embodiment 2

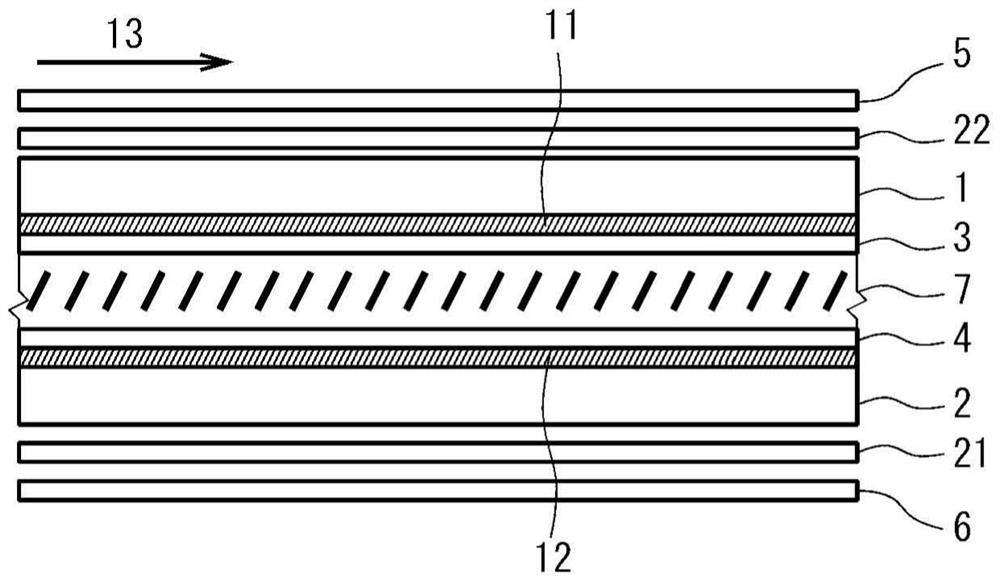

[0079] ・Structure of the liquid crystal display device: the structure of the second embodiment (see image 3 and Figure 4 )

[0080] ・First optical plate: An optical plate with an in-plane phase difference of 55 nm, a thickness direction phase difference of 220 nm, and negative biaxial optical anisotropy

[0081] ・Second optical plate: An optical plate with an in-plane retardation of 330 nm and positive uniaxial optical anisotropy

[0082] Figure 12 (B) is a graph showing the calculation results of the spectroscopic spectrum in Example 2. As shown in the figure, also in the liquid crystal display device of Example 2, the same spectroscopic spectrum as that of the above-mentioned Example 1 was obtained, so it is considered that the change in color tone with respect to the change in viewing angle is suppressed as compared with the comparative example.

Embodiment 3

[0084] ・Structure of the liquid crystal display device: the structure of the second embodiment (see image 3 and Figure 4 )

[0085] ・First optical plate: An optical plate with an in-plane phase difference of 55 nm, a thickness direction phase difference of 220 nm, and negative biaxial optical anisotropy

[0086] ・Second optical plate: An optical plate with an in-plane retardation of 255 nm and positive uniaxial optical anisotropy

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com