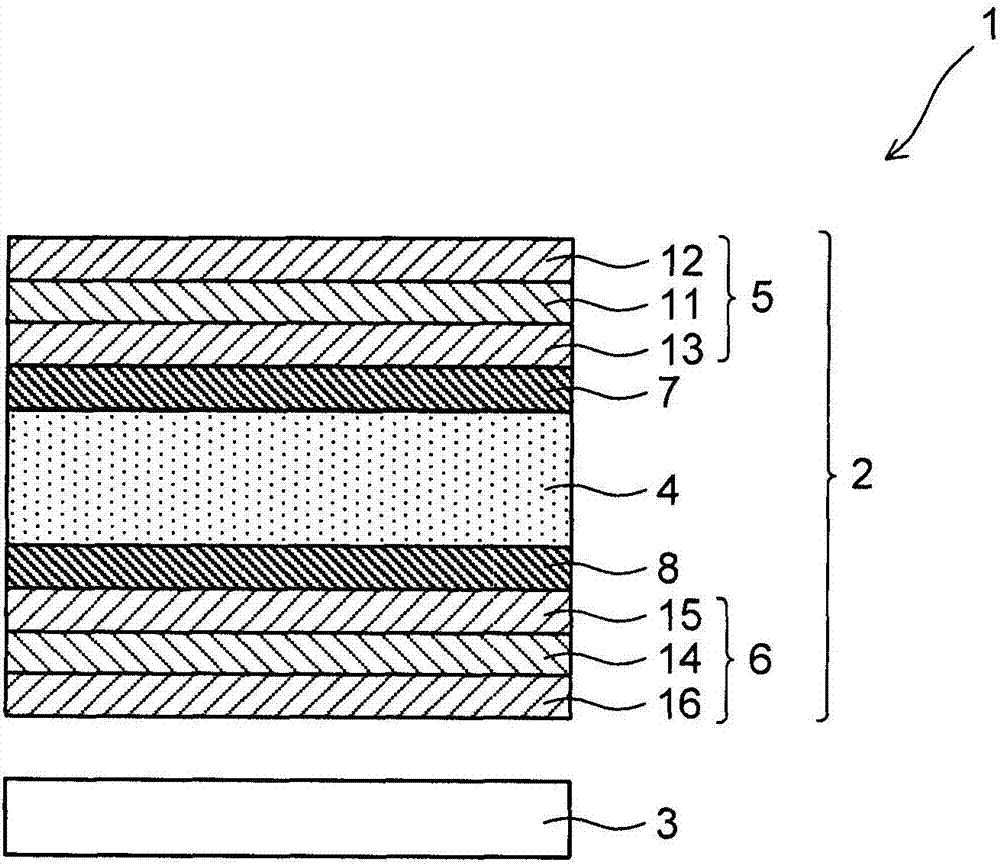

Phase Difference Film, Polarizing Plate And Liquid Crystal Display Device

A retardation film and polarizer technology, applied in polarizing components, instruments, optics, etc., can solve problems such as increased production costs, damage to the quality of polarizers, and reduced productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

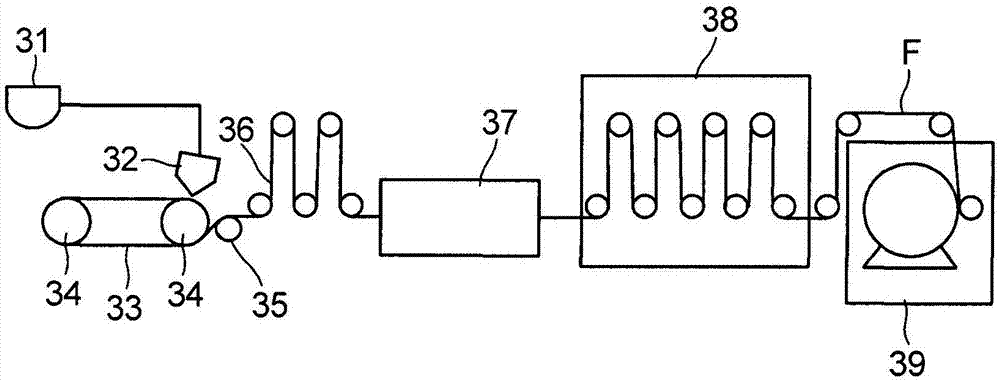

Method used

Image

Examples

Synthetic example

[0195]

[0196] Synthesis examples of sugar esters are shown below.

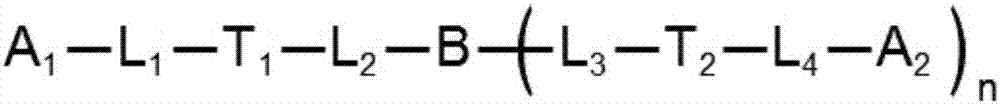

[0197] 【Chemical 14】

[0198]

[0199] Exemplary compound A-1

[0200] Exemplary compound A-2

[0201] Exemplary compound A-3

[0202] Exemplary compound A-4

[0203] Exemplary compound A-5

[0204] 34.2g (0.1 mol) of sucrose, 180.8g (0.8 mol) of benzoic anhydride, and 379.7g (4.8 mol) of pyridine were respectively charged in a four-headed retort with a stirring device, a reflux condenser, a thermometer and a nitrogen inlet tube , the temperature was raised while bubbling nitrogen gas from the nitrogen gas introduction tube with stirring, and the esterification reaction was performed at 70° C. for 5 hours. Next, reduce the pressure in the retort to 4×10 2 Below Pa, after distilling off excess pyridine at 60°C, depressurize the retort to below 1.3×10Pa, raise the temperature to 120°C, and remove most of benzoic anhydride and benzoic acid generated. Next, 1 L of toluene and 300 g of a 0.5...

Embodiment

[0472] The following examples are given to describe the present invention in detail, but the present invention is not limited to these examples. In addition, the expression of "part" or "%" is used in an Example, Unless otherwise specified, it means "part by mass" or "% by mass".

[0473] As nitrogen-containing heterocyclic compounds used in the following examples and comparative examples, the following nitrogen-containing heterocyclic compounds were prepared.

[0474] 【Chemical 27】

[0475]

[0476]

[0477] [Production of Retardation Film A1]

[0478]

[0479] Silica fine particles (Aerosil R972V manufactured by Japan Aerosil Co., Ltd.)

[0480] 11 parts by mass

[0481] 89 parts by mass of ethanol

[0482] The above was stirred and mixed with a dissolver for 50 minutes, and then dispersed with Mantongorin.

[0483]

[0484] The microparticle dispersion 1 was slowly added to the dissolution tank filled with dichloromethane while stirring well. Furthermore, dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moisture permeability | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com