Aqueous compositions and hardcoats

A water-based composition, hard coating technology, applied in coatings, layered products, instruments, etc., can solve problems such as easy injury, achieve high hardness, inhibit the rise of haze, and excellent optical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0110] (Preparation of an aqueous solution for an easily bonding layer)

[0111] The aqueous solution for an easily bonding layer was prepared by the following mix|blending.

[0112] 8 parts by mass of tin oxide particle dispersion

[0113] (Ishihara Sangyo Co., Ltd., FS-10D)

[0114] 2.8 parts by mass of polyurethane

[0115] (Mitsui Chemicals Co., Ltd., Takelac WS-5100)

[0116] 4.2 parts by mass of crosslinking agent

[0117] (manufactured by Nisshinbo Chemical Co., Ltd., 10% dilution of Carbodilite V-02-L2)

[0118] Surfactant A0.2 parts by mass

[0119] (manufactured by Sanyo Chemical Industry Co., Ltd., Sanded BL 10% aqueous solution, anionic)

[0120] Surfactant B 0.2 parts by mass

[0121] (Sanyo Chemical Industry Co., Ltd., a 10% dilution of Naroacti CL-95, non-ionic)

[0122] 84.6 parts by mass of water

[0123] (Preparation of Aqueous Composition for Hard Coating)

[0124] The preparation of the aqueous hard-coat composition was performed so that the follo...

Embodiment 2~8 and comparative example 1~4

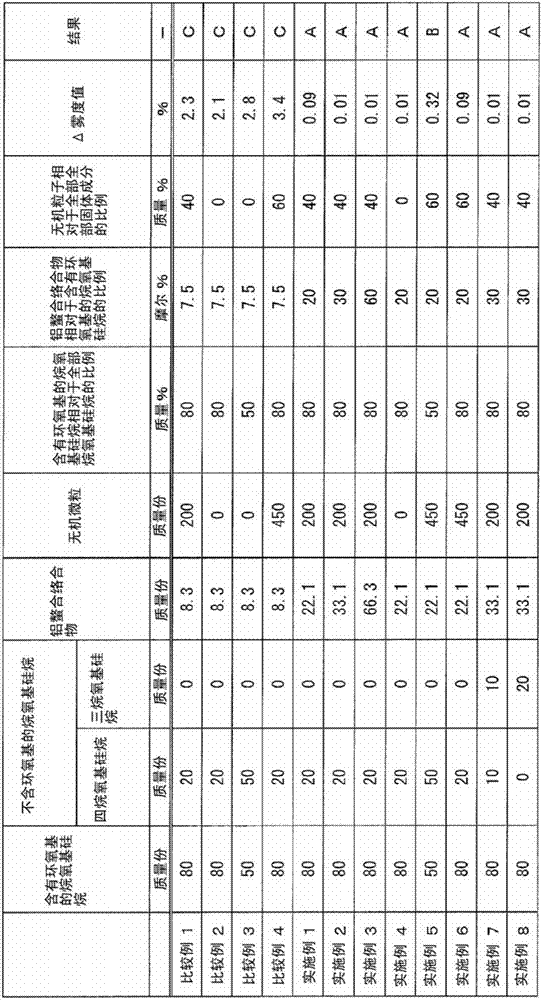

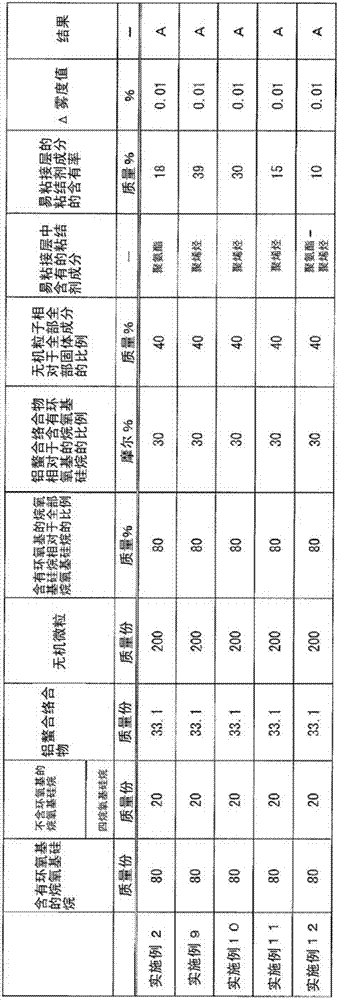

[0145] An easily bonding layer was formed in the same manner as in Example 1, and the aqueous solution for a hard coat layer prepared so as to achieve the combination in Table 1 was applied in the same manner as in Example 1 to prepare a sample.

[0146] (evaluate)

[0147] Alkali treatment

[0148] The samples of Examples 1 to 8 and Comparative Examples 1 to 4 were immersed in a 5% NaOH aqueous solution at 30° C. for 10 minutes, and the haze values before and after the treatment were measured. The haze measurement machine NDH5000 by Nippon Denshoku Industries Co., Ltd. was used for the measurement of haze. The increase in haze value is shown in Table 1. The evaluation that the increase of the haze value is 0.1 or less is A, the evaluation of more than 0.1 and 0.5 or less is B, and the evaluation of more than 0.5 is C.

[0149] Table 1

[0150]

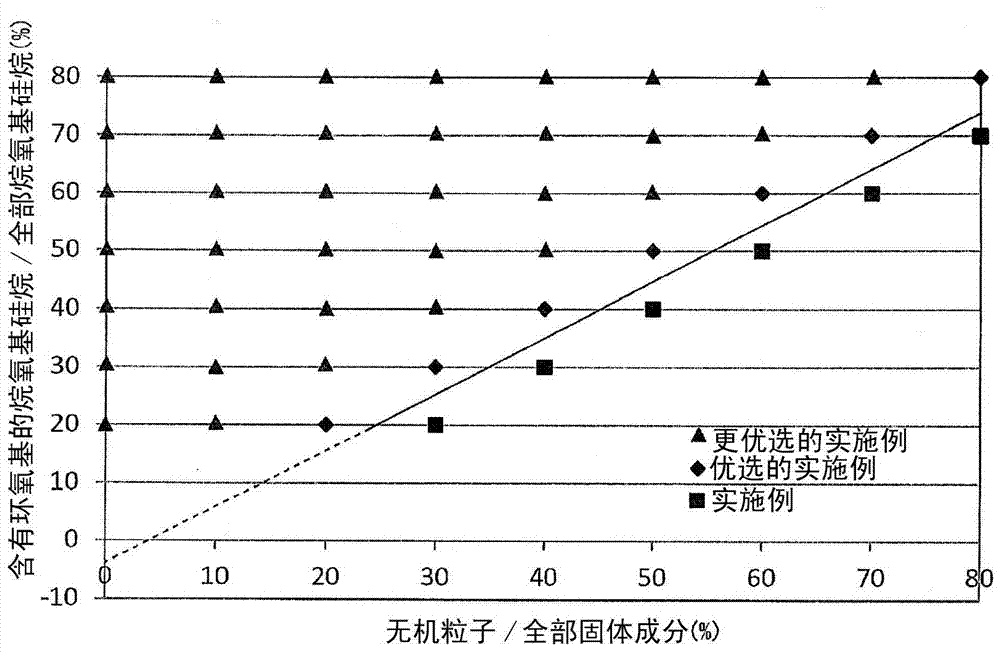

[0151] As shown in Table 1, in Comparative Examples 1 to 4, since the content of the aluminum chelate complex was low, the ...

Embodiment 9

[0156] (Preparation of an aqueous solution for an easily bonding layer)

[0157] The aqueous solution for an easily bonding layer was prepared according to the following mix|blending.

[0158] Tin oxide particle dispersion 8 parts by mass

[0159] (Mitsubishi Materials Co., Ltd., SDL-2)

[0160] Polyolefin 9 parts by mass

[0161] (Manufactured by UNITIKA Co., Ltd., AROBES SE-1013N)

[0162] Cross-linking agent 2 parts by mass

[0163] (manufactured by Nisshinbo Chemical Co., Ltd., 10% dilution of Carbodilite V-02-L2)

[0164] Surfactant A 2 parts by mass

[0165] (manufactured by Sanyo Chemical Industry Co., Ltd., Sanded BL 10% aqueous solution, anionic)

[0166] Surfactant B 2 parts by mass

[0167] (Sanyo Chemical Industry Co., Ltd., a 10% dilution of Naroacti CL-95, non-ionic)

[0168] 77 parts by mass of water

[0169] (Formation of easy bonding layer and hard coat layer)

[0170]The corona treatment was given to the PET base material, the said aqueous solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com