SFC polymer ceramic fiber monofilament material and preparation method thereof

A ceramic fiber and monofilament technology is applied in the field of SFC poly-ceramic fiber monofilament material and its preparation, which can solve the problems of unusability and poor alkali resistance, and achieve high elastic modulus, low elongation, and good aging resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

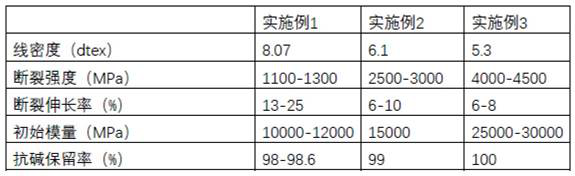

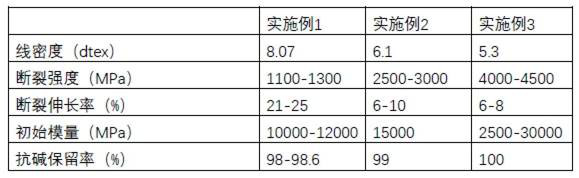

Embodiment 1

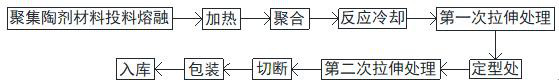

[0031] Such as figure 1 , step 1, preparing the original monofilament of mixed SFC material

[0032] a. Put polyethylene terephthalate slices in a stirring dryer, stir while heating, and dry them to obtain dry polyester and ceramic materials, wherein the drying temperature is 120°C, and the dried polyethylene terephthalate The moisture content of ethylene phthalate and ceramic powder is 1%;

[0033] b. Add the anti-alkali modification additive to the dried polyester chips and ceramic powder, stir and mix well, then send it into the screw melt extruder, heat and melt to obtain a polyester mixture, in which polyterephthalene The weight ratio of ethylene glycol formate and ceramic powder is 89:10:1, the speed of the screw extruder is 28rpm, the absolute pressure inside the screw extruder is 8.5MPa, and the shell of the screw extruder is heated by electricity, The diameter of the screw is 120mm, the aspect ratio of the screw is 30:1, the temperature of the 1-6 zone of the screw ...

Embodiment 2

[0047] Such as figure 1 , step 1, preparing the original precursor wire of polyester ceramic SFC material

[0048] a. Put polyethylene terephthalate slices in a stirring dryer, heat, stir, and dry to obtain a dried polyester ceramic material, wherein the drying temperature is 120°C, and the dried polyethylene terephthalate The moisture content of the ester is 0.5%;

[0049] b. Add the anti-alkali modified additive ceramic powder into the dry polyethylene terephthalate slices, stir and mix evenly, then send it into the screw melt extruder, heat and melt, mix evenly, and make Obtain polyester mixture, wherein, the weight ratio of polyethylene terephthalate is 80:5:5, the rotating speed of screw extruder is 20rpm, and the absolute pressure in the screw extruder is 9.0MPa, and the screw extruder The temperature of each zone is: 228°C, 256°C, 276°C, 280°C, 272°C, 274°C: the temperature of the extrusion head of the screw extruder is 274°C;

[0050] c. Extrude the molten polyester...

Embodiment 3

[0063] Such as figure 1 , step 1, preparing SFC precursor

[0064] a. Put polyethylene terephthalate slices and ceramics in a stirring dryer, heat, stir, and dry to obtain dry polyester and ceramic materials, wherein the drying temperature is 120 ° C, and the SFC moisture content after drying is 1%;

[0065] b. Add the anti-alkali modification additive and polyester ceramics into the dried polyethylene terephthalate slices, stir and mix well, then send them into the screw melt extruder, heat and melt, mix evenly, and make Obtain polyester mixture, wherein, the weight ratio of polyethylene terephthalate, polyethylene and polypropylene is 90:15:0.5, the rotating speed of screw extruder is 15rpm, and the absolute pressure in the screw extruder is 9.5 MPa, the temperature of each zone of the screw extruder is: 234°C, 250°C, 274°C, 276°C, 266°C, 270°C: the temperature of the extrusion head of the screw extruder is 270°C;

[0066] c. Extrude the molten polyester ceramic mixture t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com