a battery

A technology of batteries and batteries, applied to batteries. field, it can solve the problems of no expansion space for the battery core, consistency deviation of the battery case, heat resistance of the glue, etc., and achieve the effect of avoiding damage to the case

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

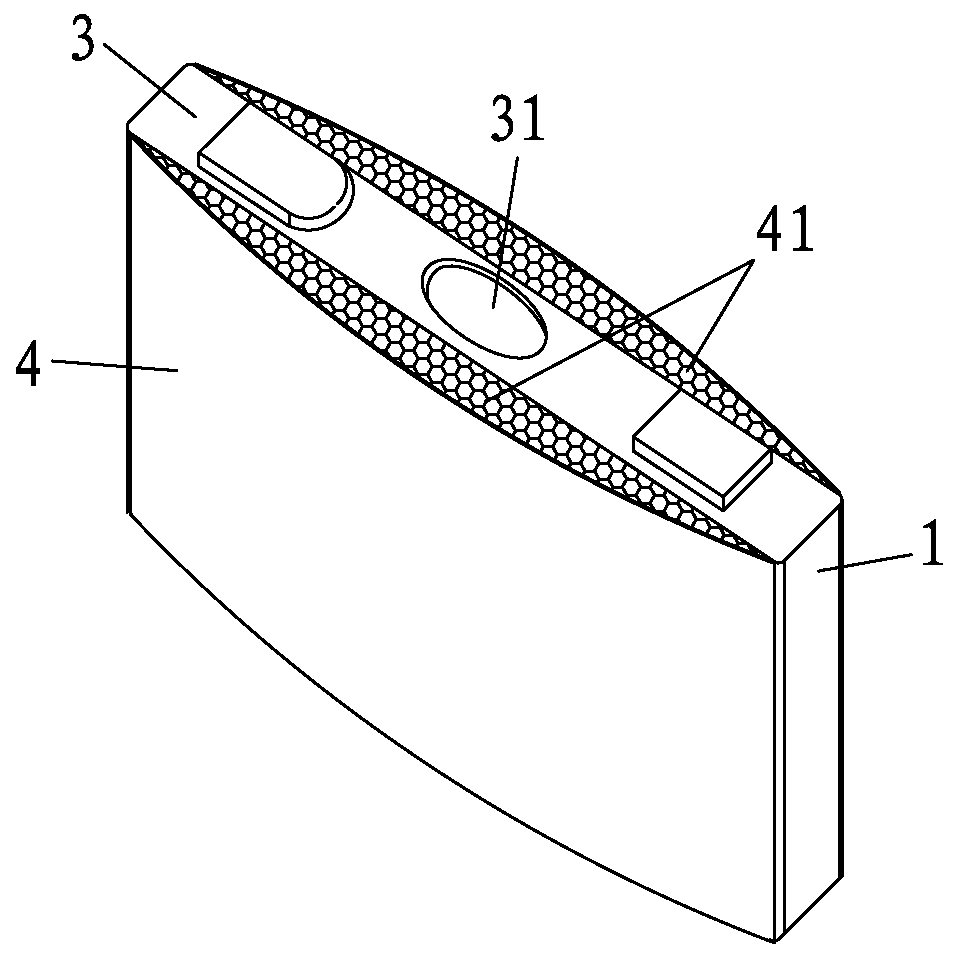

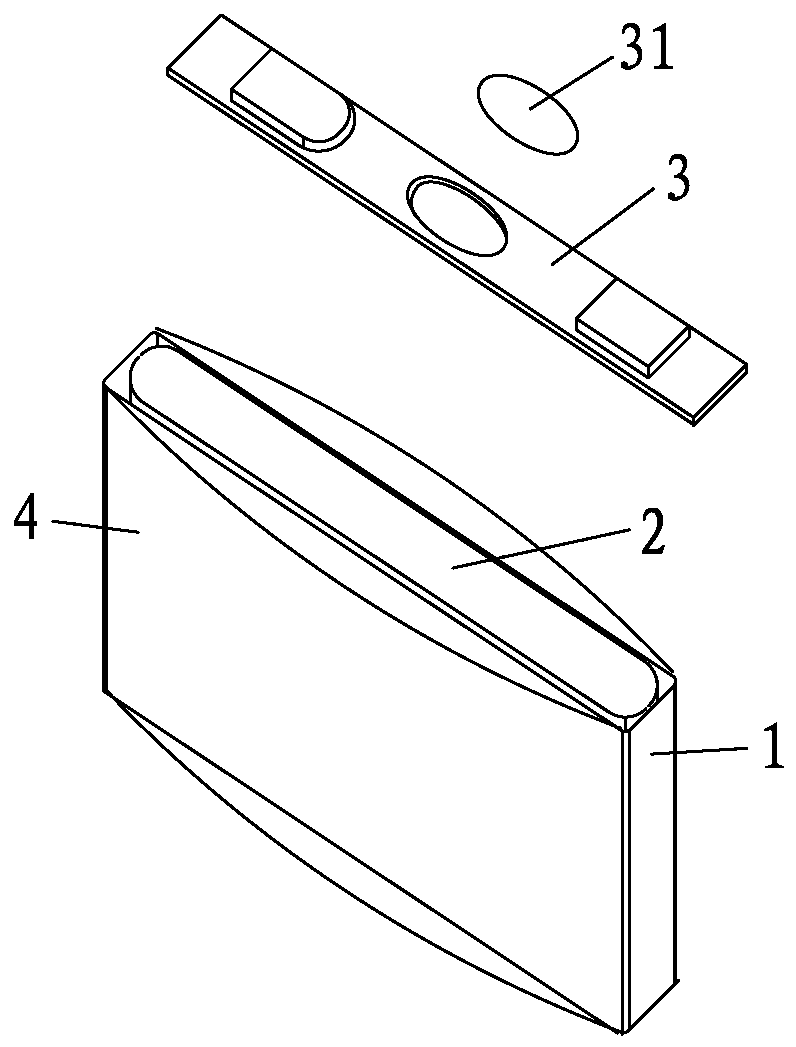

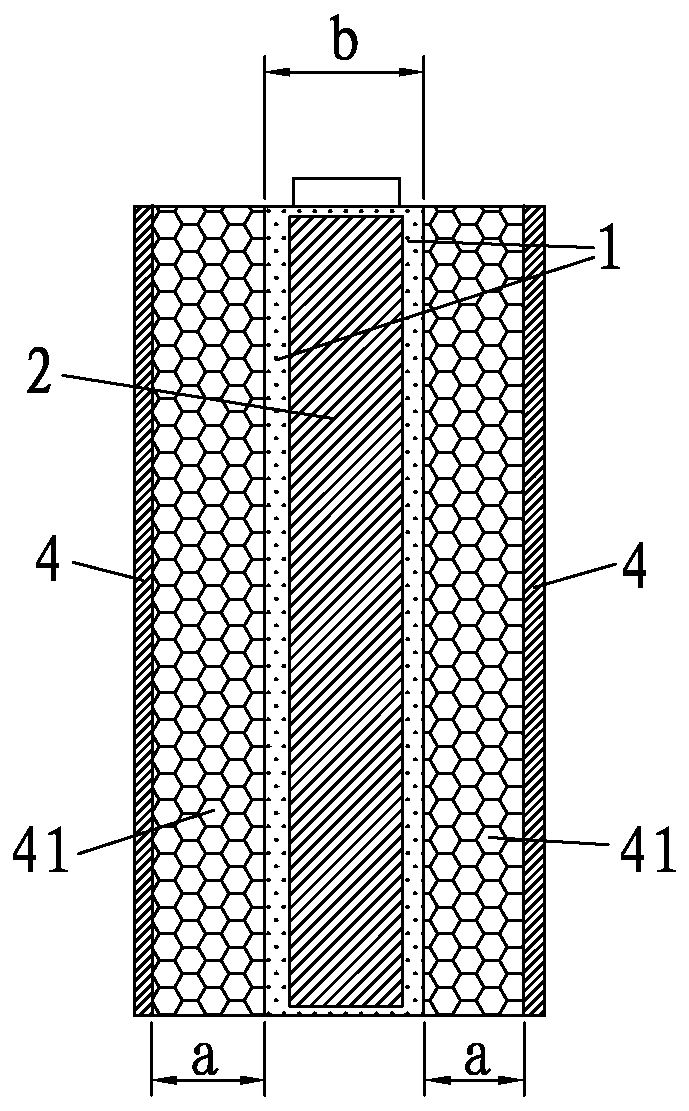

[0031] Such as Figure 1~3 As shown, a battery includes a casing 1 and a battery cell 2 housed in the casing 1. The structure also includes an outer wrapping structure 4 with an elastic function. The outer wrapping structure 4 is arranged outside the casing 1. The outer wrapping structure 4 and A gap 5 is provided between the housings 1 . Due to the existence of the above structure, when the battery is fixed by the module fixture, the internal loosening of the battery cell 2 due to the thickness change of the battery cell 2 will not cause the battery cell 2 to be loose and cannot be positioned and assembled, and automatic production can be realized, and the production efficiency is greatly improved. If there is no outsourcing structure 4, when the size of the fixture and the battery is excessive, the module will damage the cell 2, squeeze the cell 2, and cause a safety accident. Even if it is squeezed hard, the cycle life will be shortened due to no expansion space ; When the...

Embodiment 2

[0038] Such as Figure 4 As shown, the difference from Example 1 is that the length of the connecting side of the outsourcing structure 4 in this embodiment is shorter than the length of the connecting side of the case, so that the outsourcing structure 4 is arranged outside the battery case, which saves material costs and reduces battery life. the weight of.

[0039] Other structures are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0041] Such as Figure 5 As shown, the difference from Embodiment 2 is that the outsourcing structure 4 of this embodiment is set as a layered structure, and the layered structure is formed by superimposing two arc-like outsourcing structures. Of course, multiple arcs can also be superimposed as required. In the sheet-like outsourcing structure, in addition, outsourcing structures 4 of different structures can also be superimposed.

[0042] Other structures are the same as those in Embodiment 2, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com