Nano-pore polymer electrolyte film and its preparation method

A technology of electrolyte membrane and polymer, applied in the direction of secondary battery parts, etc., can solve the problems of poor product uniformity and stability, difficult control of thermal compound process and solvent extraction process, and low yield of battery products, so as to reduce production The effect of low cost, low product cost, and excellent physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

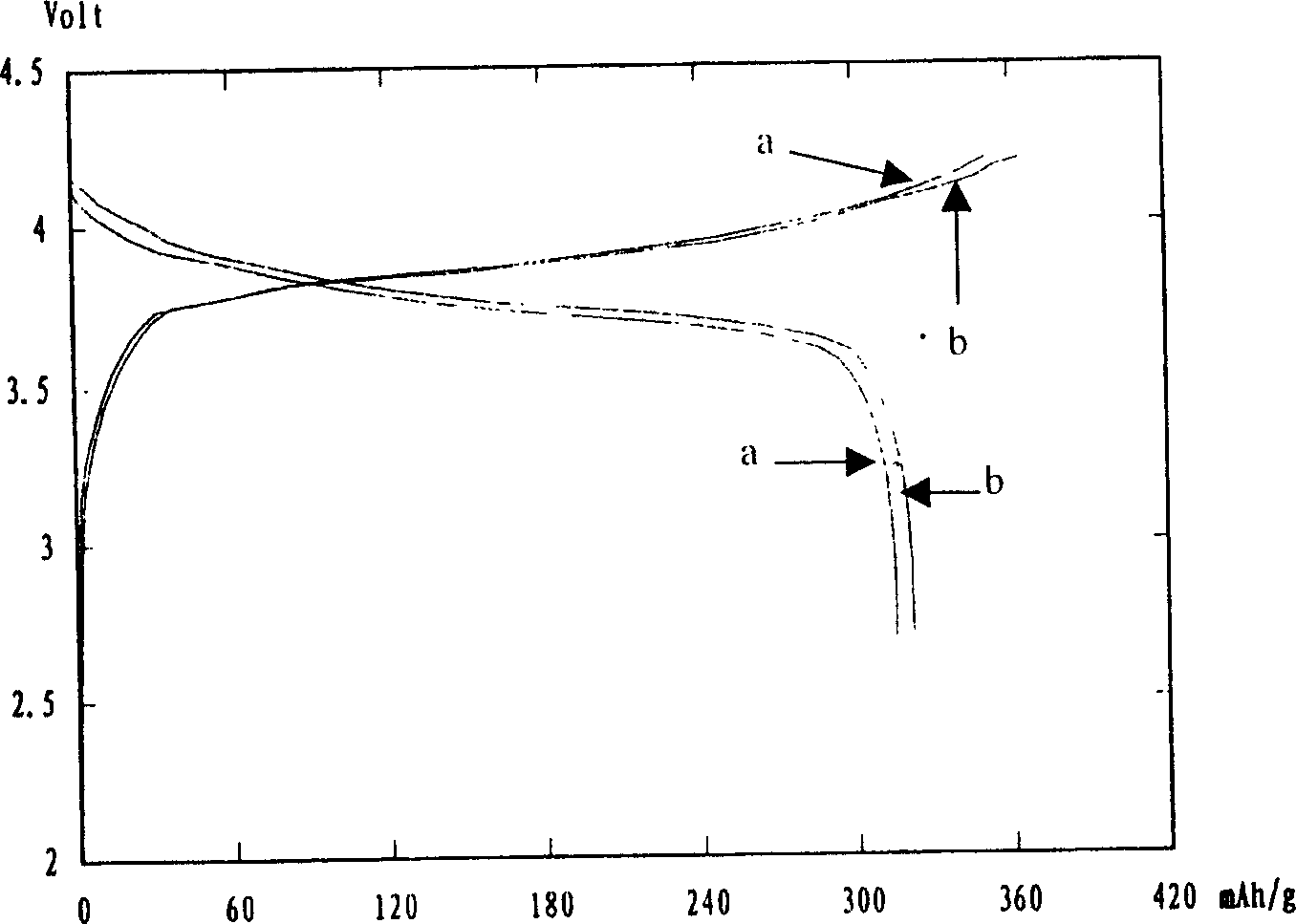

[0031] Dissolve 80 grams of EVA resin with a melt index of 3 and a vinyl acetate content of 14% in 400 milliliters of toluene, add 160 milliliters of acrylonitrile monomer and 30 milliliters of triethyl phosphate, and then heat up to 80 °C ± 2 °C , start to drop 100 milliliters of toluene solution containing 0.4 gram dicumyl peroxide and 10 gram trimethylolpropane triacrylate, dropwise for about 3 hours, then continue to react at this temperature for 8 hours. Adding 120 grams of concentration after the reaction is finished is 20% gas phase method SiO 2 / triethyl phosphate slurry and stirred for 2 hours. The reaction product is scraped on the glass plate or directly coated on the carbon negative electrode sheet, and the microporous polymer electrolyte membrane or the microporous polymer electrolyte / carbon negative electrode composite electrode sheet is formed after the solvent is volatilized. The performance test results of the microporous polymer electrolyte membrane are show...

Embodiment 2

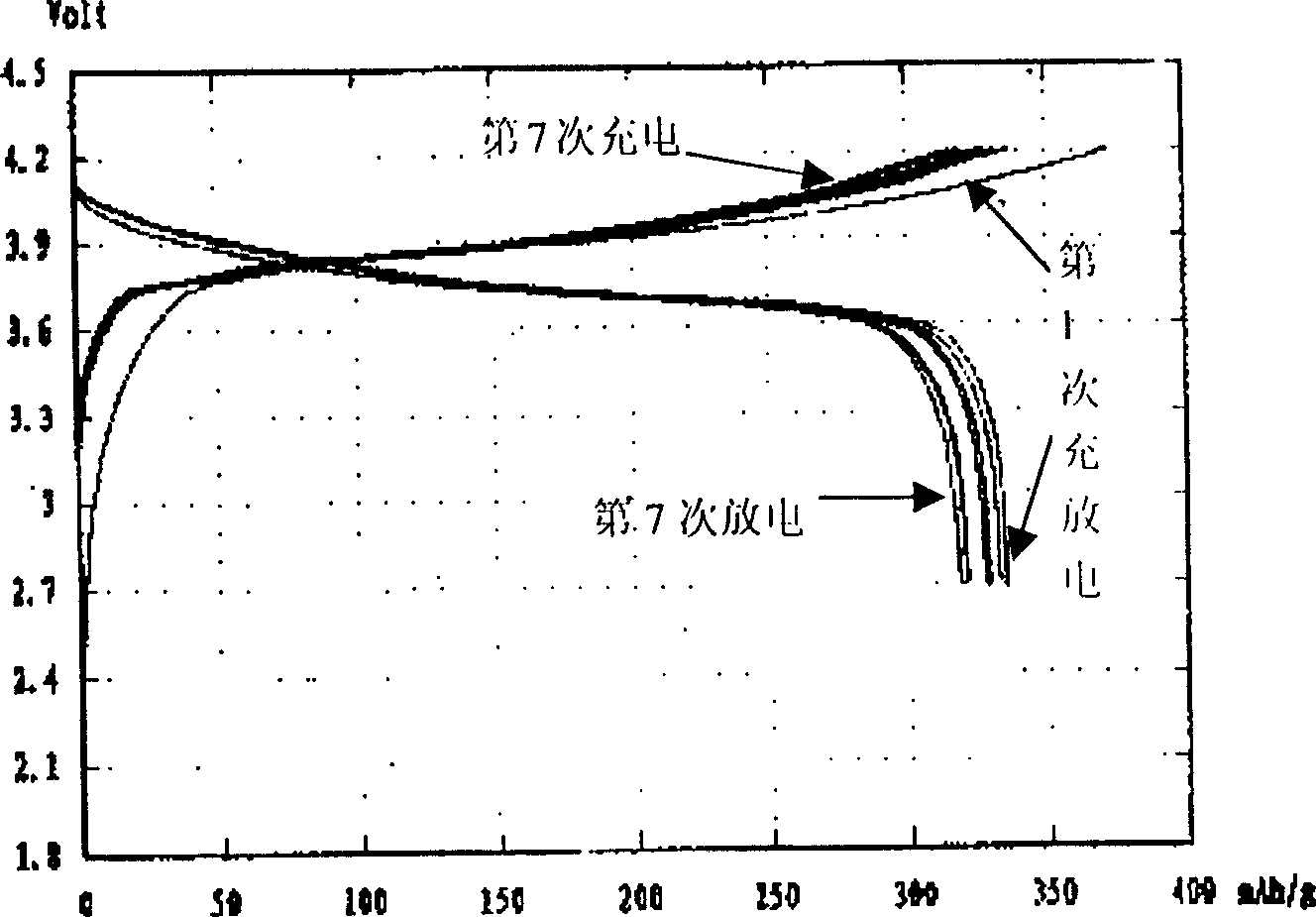

[0037] Dissolve 80 grams of EVA resin with a melt index of 14 and a vinyl acetate content of 25% in 400 milliliters of toluene, add 240 milliliters of acrylonitrile monomer and 30 milliliters of triethyl phosphate, and then heat up to 80 °C ± 2 °C , start to drop 100 ml of toluene solution containing 0.6 gram of dicumyl peroxide and 15 gram of trimethylolpropane triacrylate, the time of dropping is about 3 hours, and the total reaction time is 12 hours. Adding 200 grams of concentration after the reaction is 50% Al 2 o 3 / triethyl phosphate slurry and stirred for 2 hours. The reaction product is scraped on the glass plate or directly coated on the carbon negative electrode sheet, and the microporous polymer electrolyte membrane or the microporous polymer electrolyte / carbon negative electrode composite electrode sheet is formed after the solvent is volatilized.

[0038] The performance test results of the microporous polymer electrolyte membrane are shown in Table 1.

[0039...

Embodiment 3

[0041] Except that the cross-linking agent is divinylbenzene and the dosage is 10 grams, the same operation as in Example 2 was followed to obtain a polymer electrolyte membrane for lithium-ion batteries. The performance test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrochemical stability window | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com