Continuous adjustable nonresistive bidirectional coupler

A two-way coupling and connector technology, applied in connecting devices, waveguide-type devices, electrical components, etc., can solve the problems of inability to achieve coupling degree adjustability, inability to achieve bidirectional transmission, and inability to achieve interchangeability, to ensure batch consistency. performance, optimize the layout of signal traces, reduce material costs and labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

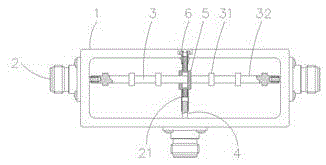

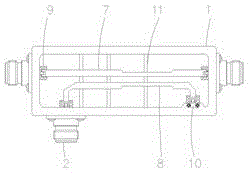

[0024] Example: Combine Figure 1A — Figure 1B , the continuously adjustable non-impedance bidirectional coupler of this embodiment includes:

[0025] Cavity 1, connector 2, coupling main rod 3, coupling sub-rod 4, adjusting rod 5 and adjusting nut 6;

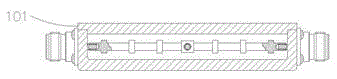

[0026] The cavity 1 is square, with a square cavity inside, and connector mounting holes on three sides, and the cover plate 101 is installed on the cavity;

[0027] Both ends of the coupling main rod 3 are connected with the connector 2;

[0028] One end of the coupling sub-rod 4 is provided with an elastic hole, which is connected with the central conductor 21 of the connector 2, and the other end is provided with a threaded hole, which is connected with the adjustment rod 5;

[0029] One end of the adjusting rod 5 is connected with the coupling auxiliary rod 4, and the other end is connected with the adjusting nut 6;

[0030] In the specific implementation, the cavity 1, the cover plate 101, the adjusting nut 6, the cou...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap