heat sink

A technology of heat dissipation device and heat dissipation parts, which is applied in the direction of cooling/ventilation/heating transformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The above-mentioned purpose of the present invention and its structural and functional characteristics will be described based on the preferred embodiments of the accompanying drawings.

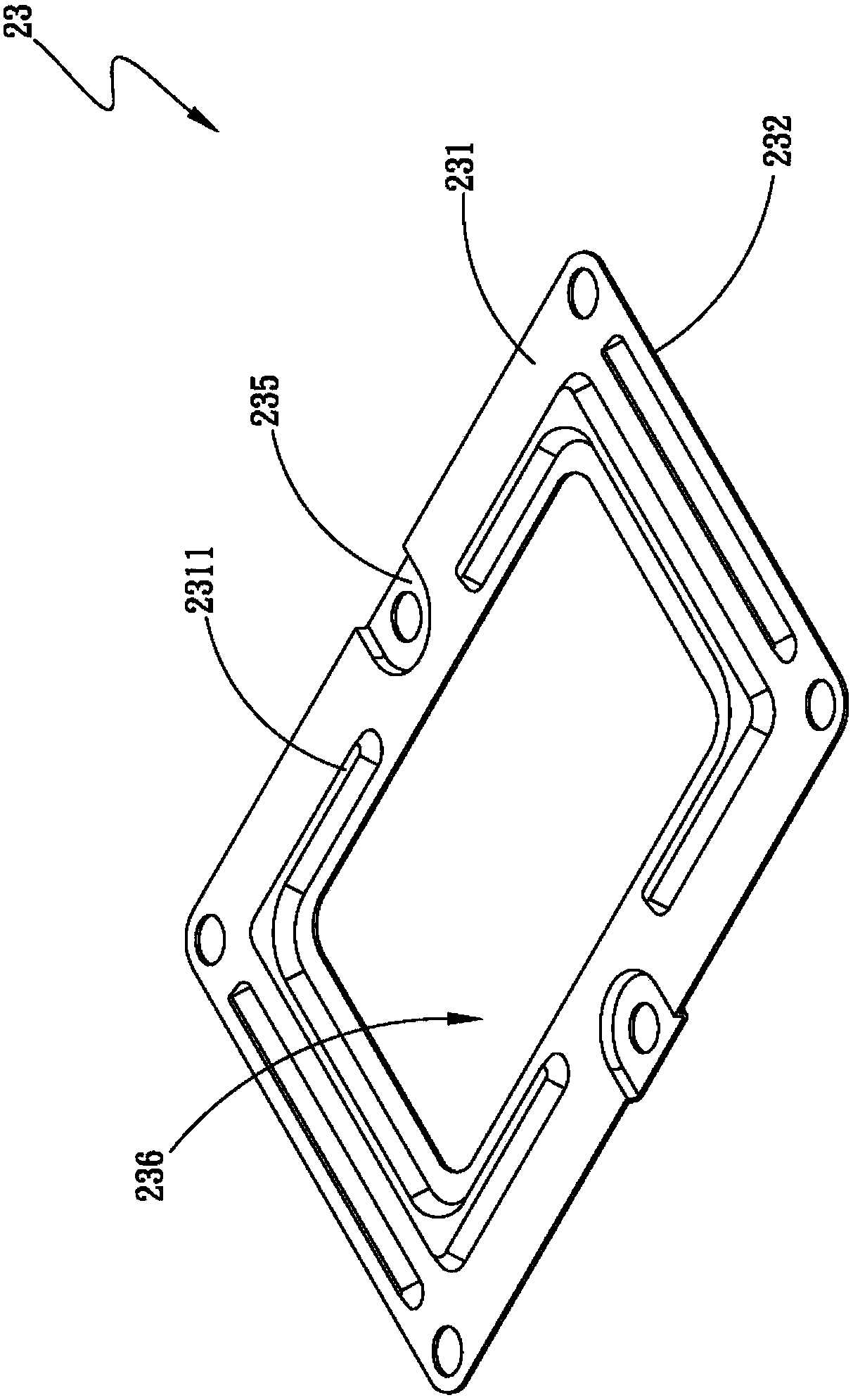

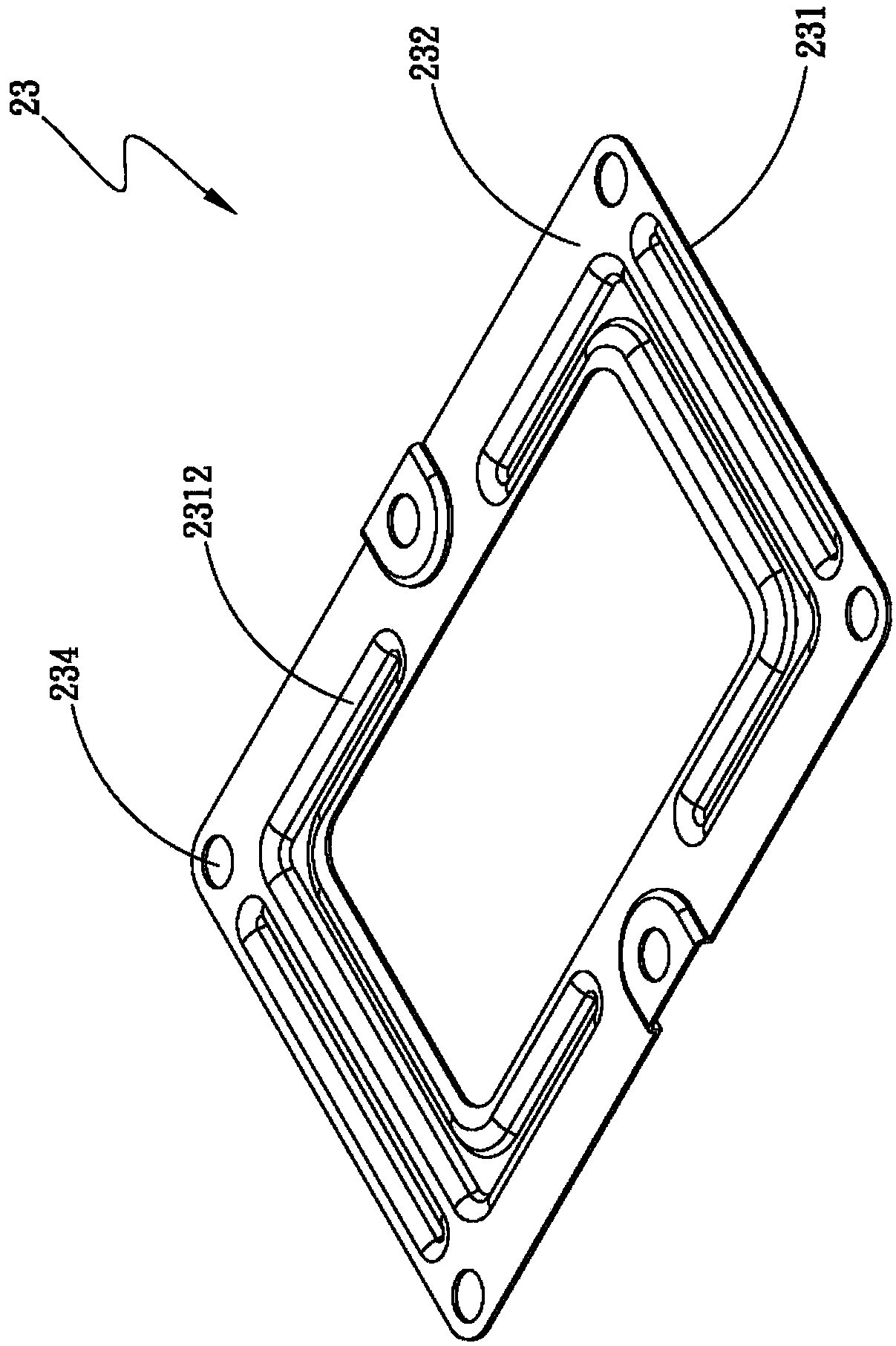

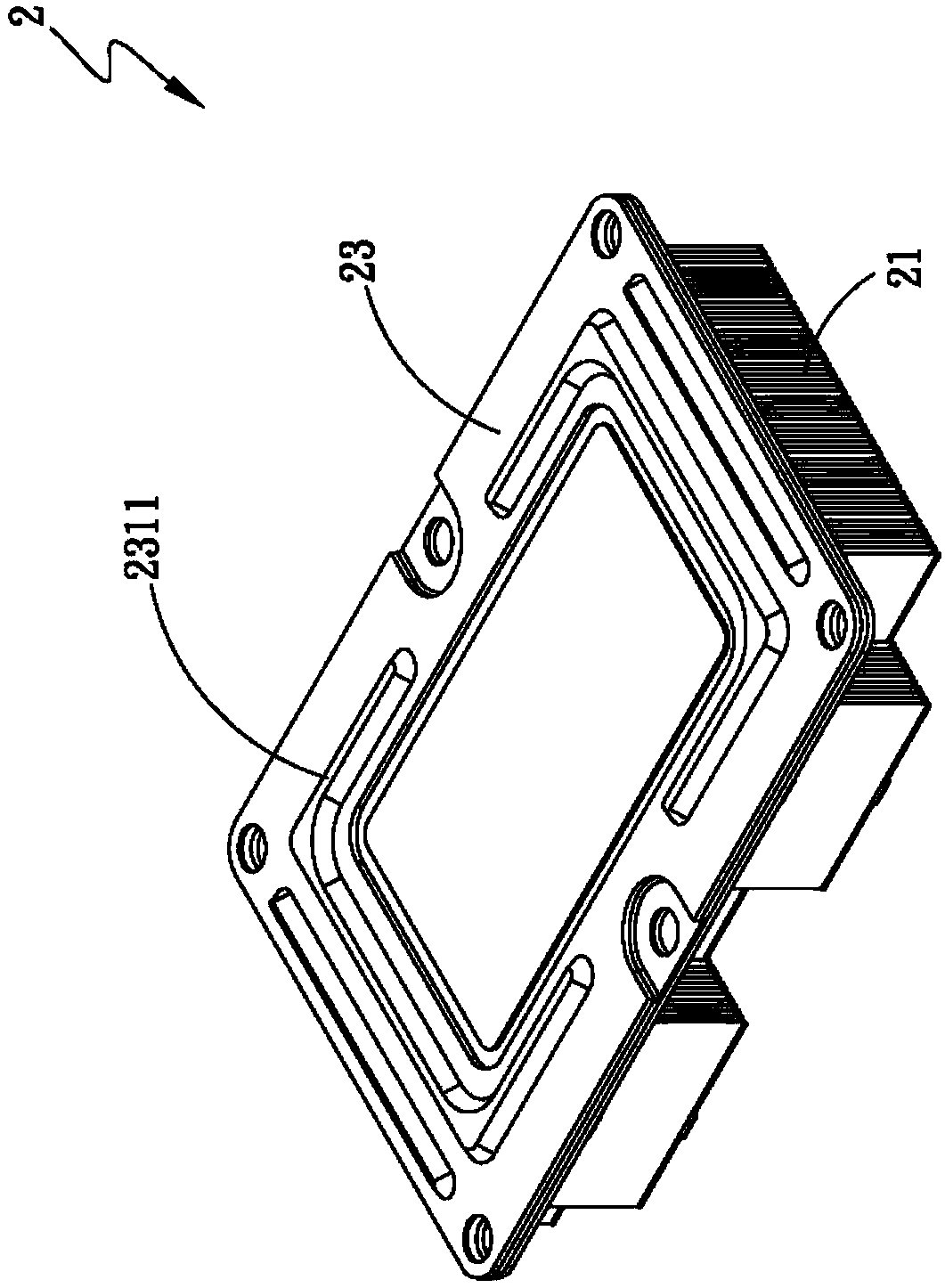

[0050] Such as Figure 1A and 1B And 2A and 2B are the perspective view of the support member of the first embodiment of the heat dissipation device of the present invention and the three-dimensional exploded view and three-dimensional combination view of the heat dissipation device. As shown in the figure, a heat dissipation device 2 includes a heat dissipation member 21 and a heat conduction Part 22 and a supporting part 23, the cooling part 21 has several cooling fins 211 and forms at least one depression 212;

[0051] One side of the heat conduction element 22 is attached to the heat dissipation element 21 correspondingly, and at least one joint portion 224 and at least one through hole 225 are formed on opposite sides of the heat conduction element 22 ;

[0052] The supporting me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com