Steel pipe and machining process thereof

A processing technology, steel pipe technology, applied in the direction of metal processing equipment, pipe components, pipeline protection, etc., can solve the problems of damage, steel pipe deformation, etc., to enhance the buffering effect, improve the cooling effect, reduce deformation or damage effect of possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

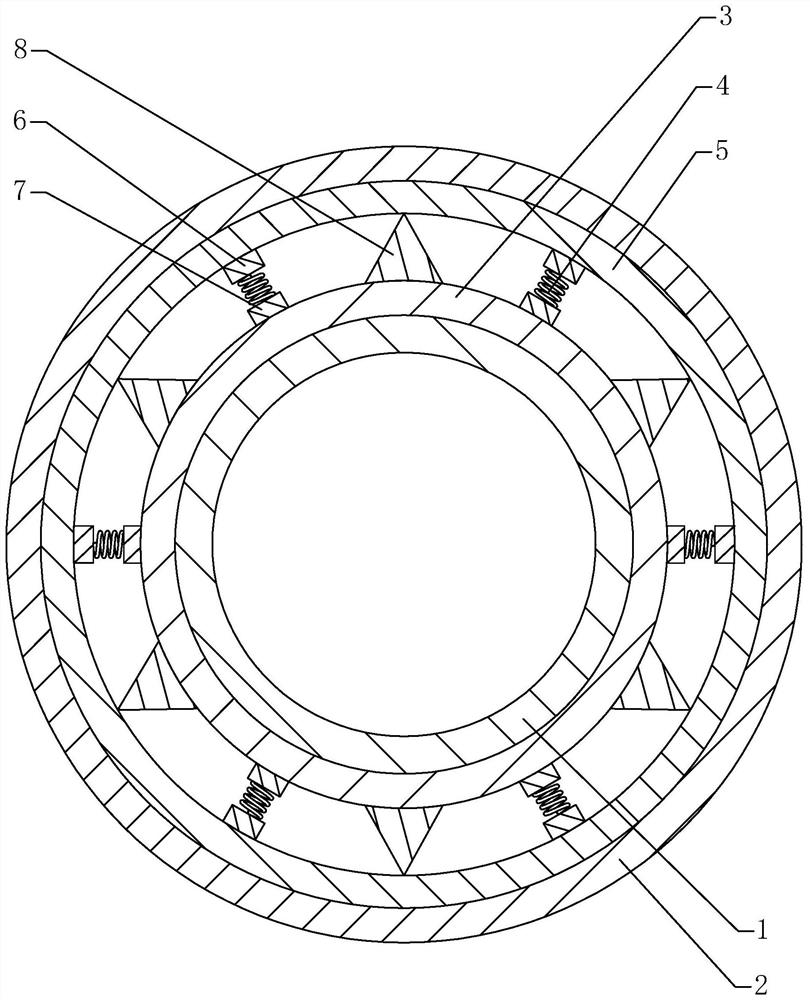

[0042] The following is attached Figure 1-2 The application is described in further detail.

[0043] The embodiment of the present application discloses a steel pipe. refer to figure 1 , a steel pipe, including a steel pipe body 1, a protective sleeve 2, a buffer and a mounting frame.

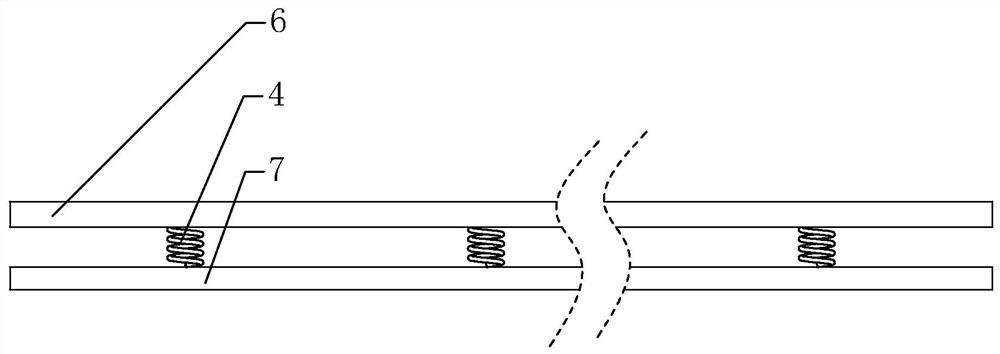

[0044] refer to figure 1 , the buffer includes a first buffer layer 3, a spring 4 and a second buffer layer 5, the first buffer layer 3 and the second buffer layer 5 are rubber sleeves, the first buffer layer 3 is arranged on the outer wall of the steel pipe body 1 by glue Above, the second buffer layer 5 is set on the inner wall of the protective sleeve 2 by glue, the protective sleeve 2 is a stainless steel tube, the protective sleeve 2 is set on the steel pipe body 1, the first buffer layer 3 and the second buffer layer 5 Arranged at intervals, the springs 4 are arranged between the first buffer layer 3 and the second buffer layer 5 .

[0045] refer to figure 1 and figure 2 , the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com