Mixer shaft for kneading and conveying device of a small fresh noodle making and selling machine

A conveying device and fresh noodle technology, which is applied in the direction of horizontal installation tool mixing/kneading, dough sheeting machine/rolling machine/rolling stick, dough forming and cutting equipment, etc., which can solve the problem that small noodle machines cannot be automated , can not adapt to noodle sales, large noodle machine can not adapt to other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

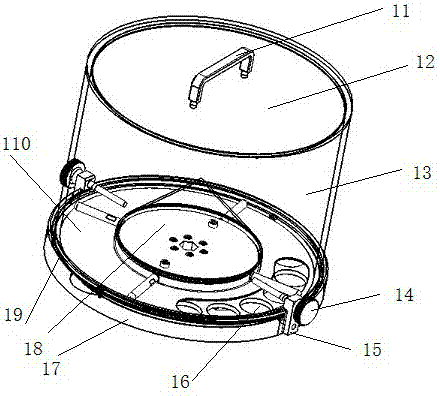

[0034] In order to further illustrate the technical solution of the present invention, the specific implementation manner of the present invention is further described in conjunction with the accompanying drawings, as figure 2 , the handle 11 is installed on the upper cover 12; in this example, transparent plexiglass is selected as the material of the upper cover 12, and the upper cover 12 is installed on the upper end of the outer cover 13. In this example, the method of movable placement is adopted, which is conducive to observation Internal working state; Outer cover 13 is installed on the lower end cap 17, selects as transparent plexiglass as the material of outer cover 13 in this example, material thickness 2 millimeters, makes the cylinder shape of diameter 280 millimeters height 260 millimeters, is conducive to observation like this The internal working state reduces the weight of the whole machine; the noodle blocking rod 14 is installed on the upper part of the noodle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com