Integrated optical element

A technology for integrating optics and optical components, applied in the field of optical fiber communication and fiber lasers, can solve the problems of large space occupation, complicated operation, large optical loss, etc., and achieve the effect of reducing space occupation, simplifying operation process, and reducing space occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

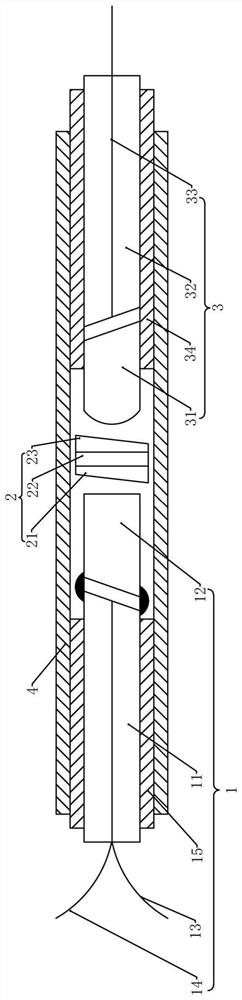

[0044] The embodiment of the present application provides an integrated optical element, which integrates the functions of a wavelength division multiplexer, an isolator, and a mode field adapter. While the functions are integrated, the occupation of workpieces is reduced and the cost is reduced.

[0045] refer to figure 1 , the integrated optical element provided in this embodiment includes a first optical component 1 , an isolator core 2 and a second optical component 3 arranged in sequence.

[0046] The first optical assembly 1 includes a first capillary 11 and a first demultiplexing lens 12 arranged in sequence, wherein the first demultiplexing lens 12 is arranged between the first capillary 11 and the isolator core 2, and the first demultiplexing lens 12 faces the isolation One end of the core 2 is coated with a WDM film, and the WDM film is a wavelength division multiplexing film, which is used to divide or combine light of two wavelengths.

[0047] The first optical as...

Embodiment 2

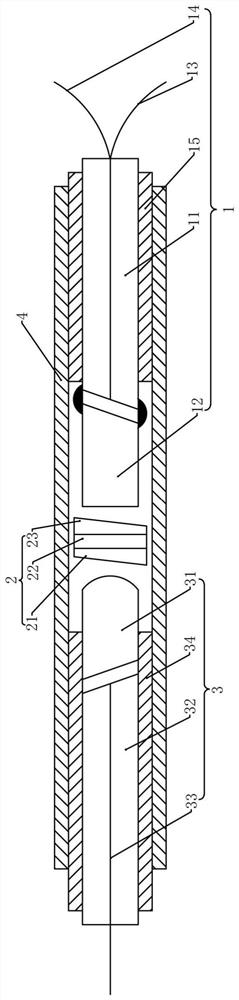

[0082] refer to figure 2 On the basis of the first embodiment, this embodiment provides another optical path for integrating optical elements. In this embodiment, the first signal light is input from the second optical component 3, passes through the isolator core 2 and then passes through the first optical component. The output of the component 1, specifically, the first signal light is transmitted from the third optical fiber 33 into the second optical component 3, enters the C lens 31 through the second capillary 32 and the flat surface of the C lens 31, and is collimated by the convex surface of the C lens 31. Straight out, after the isolator core 2, it enters the end face of the first wave splitting lens 12 coated with the WDM film, and is transmitted to the first capillary 11 through the first wave splitting lens 12, and the signal light of the first wavelength is transmitted from the first wave. Fiber 13 output.

[0083] At the same time, the second signal light is in...

Embodiment 3

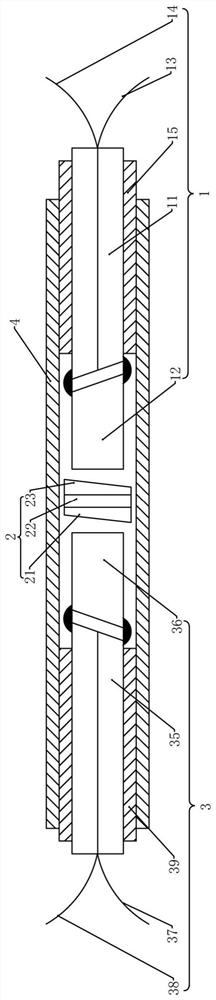

[0086] refer to image 3 , on the basis of the first embodiment, the second optical component 3 has the same structure as the first optical component 1 , and is symmetrically arranged with respect to the isolator core 2 .

[0087] The first optical assembly 1 includes a first capillary 11 and a first demultiplexing lens 12 arranged in sequence, wherein the first demultiplexing lens 12 is arranged between the first capillary 11 and the isolator core 2, and the first demultiplexing lens 12 faces the isolation One end of the core 2 is coated with a WDM film.

[0088] The first optical assembly 1 further includes a first optical fiber 13 and a second optical fiber 14 . One ends of the first optical fiber 13 and the second optical fiber 14 pass through the first capillary tube 11 and extend outside the first capillary tube 11 , and the other end of the first optical fiber 13 . One end is connected to the end face of the first capillary 11 facing the first demultiplexing lens 12, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com