Self-locking type eccentric wheel manual pressing device

A technology of a pressing device and an eccentric wheel, which is applied in the field of mechanical processing, can solve the problems of long time for pressing workpieces, low degree of automation, laborious tightening process, etc., and achieve the effect of convenient operation, strong versatility, and simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

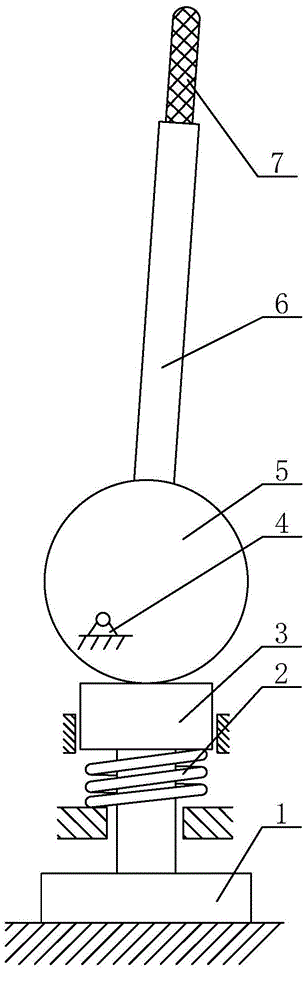

[0019] Such as figure 1 The eccentric wheel self-locking manual pressing device shown includes a T-shaped pressing head 3 for pressing the workpiece 1, a fixed support 4 for installing the eccentric wheel 5, and a fixing support 4 for driving the eccentric wheel 5 to press The drive rod 6 of the T-shaped pressing head 3 also includes an eccentric wheel 5 for driving the T-shaped pressing head 3 to press the workpiece 1 and a reset mechanism for driving the T-shaped pressing head 3 to reset upward. Spring 2; the lower end of the drive rod 6 is fixedly mounted on the eccentric wheel 5, the upper end of the drive rod 6 is fixedly mounted with a non-slip handle 7, the eccentric wheel 5 is rotatably mounted on the fixed support 4, and the The T-shaped pressing head 3 is arranged on the lower side of the eccentric wheel 5 , and the return spring 2 is arranged on the lower side of the T-shaped pressing head 3 .

[0020] In this embodiment, a bearing for reducing friction is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com