Self-adjusting anti-deflection hammer

A hammer and anti-bias technology, applied in hand hammers, manufacturing tools, striking tools, etc., can solve the problems of accidentally injuring the fingers of the surrounding people and users, not being on the axis of the nail, and the hammer hitting the fingers, etc. The probability of injuring fingers, preventing deflection, and the effect of preventing deflection of the hammer head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

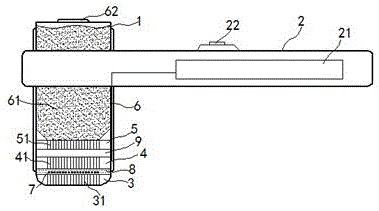

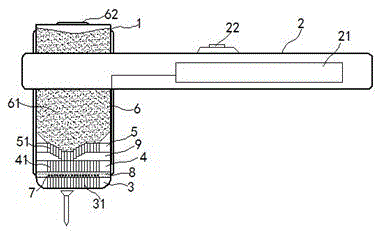

[0019] exist figure 1 , figure 2 In the shown embodiment, the self-adjusting anti-deflection hammer includes two parts: a hammer head 1 and a hammer handle 2; the hammer handle 2 is fixedly installed on the hammer head 1; 21, a control switch 22 is also installed on the hammer handle 2;

[0020] The lower part of the hammerhead 1 includes a hammering plate 3, on which hammering columns 31 are arranged in an equidistant array, each of the hammering columns 31 is parallel to each other, and each hammering column 31 Perpendicular to the plate surface of the hammering plate 3; an electromagnetic plate 4 is installed above the hammering plate 3, and electromagnetic columns 41 are arranged in an equidistant array on the electromagnetic plate 4; Permanent magnet plate 5, permanent magnet columns 51 are arranged in an equidistant array on the permanent magnet plate 5, and the magnetic pole direction of each described electromagnetic column 41 is consistent and can translate up and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com