Double-cutter breakage-proof efficient arc-plate type sliced meat cutting machine

An efficient and shatter-resistant technology, applied in metal processing and other fields, can solve problems affecting the appearance quality of output products, increasing costs, affecting oil quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

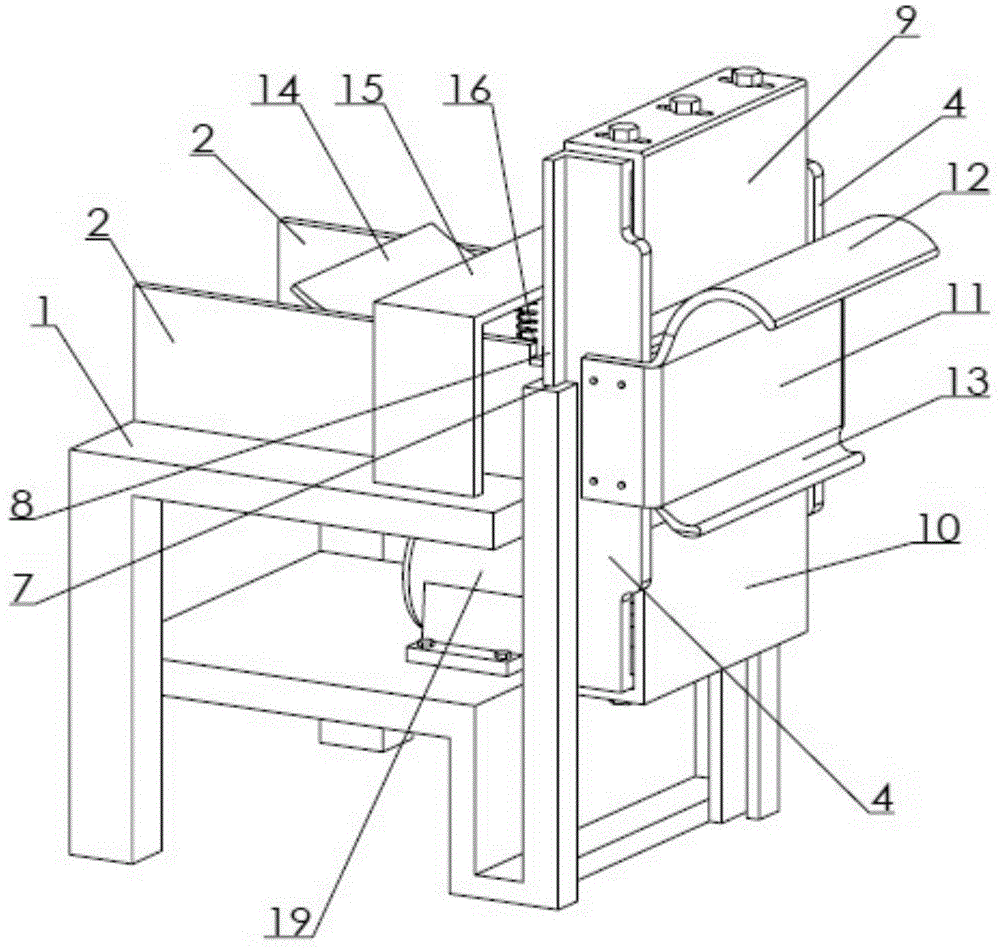

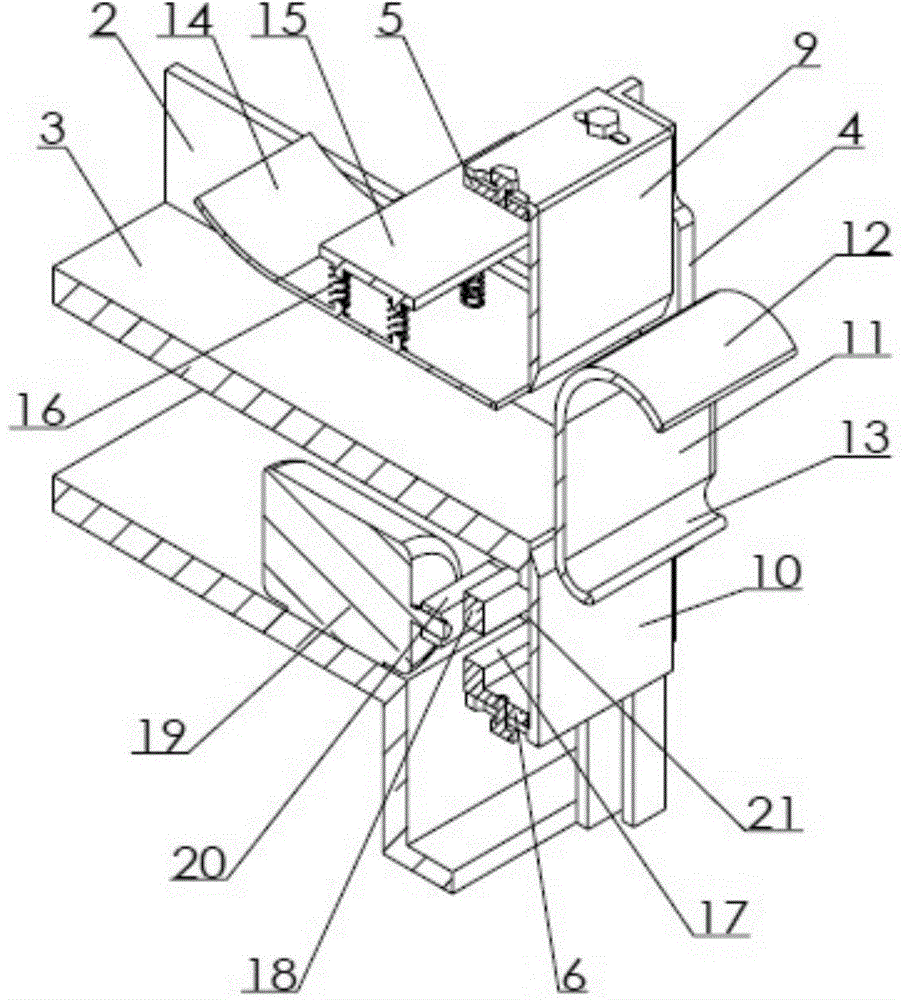

[0016] Examples of the present invention figure 1 , 2 As mentioned above, the double-knife shatter-resistant high-efficiency arc-plate meat slicer is equipped with a platform 1 and a knife holder, and there are two parallel guide plates 2 on the platform. The guide plates will form a meat supply guide groove 3, and the front ends of the guide plates are flush with the front ends of the platen. , the knife rest is provided with two side plates 4, the upper ends of the two side plates are connected by the upper beam 5, the lower ends of the two side plates are connected by the lower beam 6, the upper beam is located above the platform surface, the lower beam is located below the platform surface, and the platforms on both sides of the tool rest Vertical guide grooves 7 fixedly connected to the platform are respectively provided, and vertical guide rails 8 matched with the vertical guide grooves are respectively connected to the two side plates; upper beams are connected with upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com