Waxing device capable of enabling wax block to be clung to yarn

A wax block and yarn technology, used in textiles and papermaking, etc., can solve the problems of poor waxing effect of yarn, increased pressure between yarn and wax block, and yarn breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

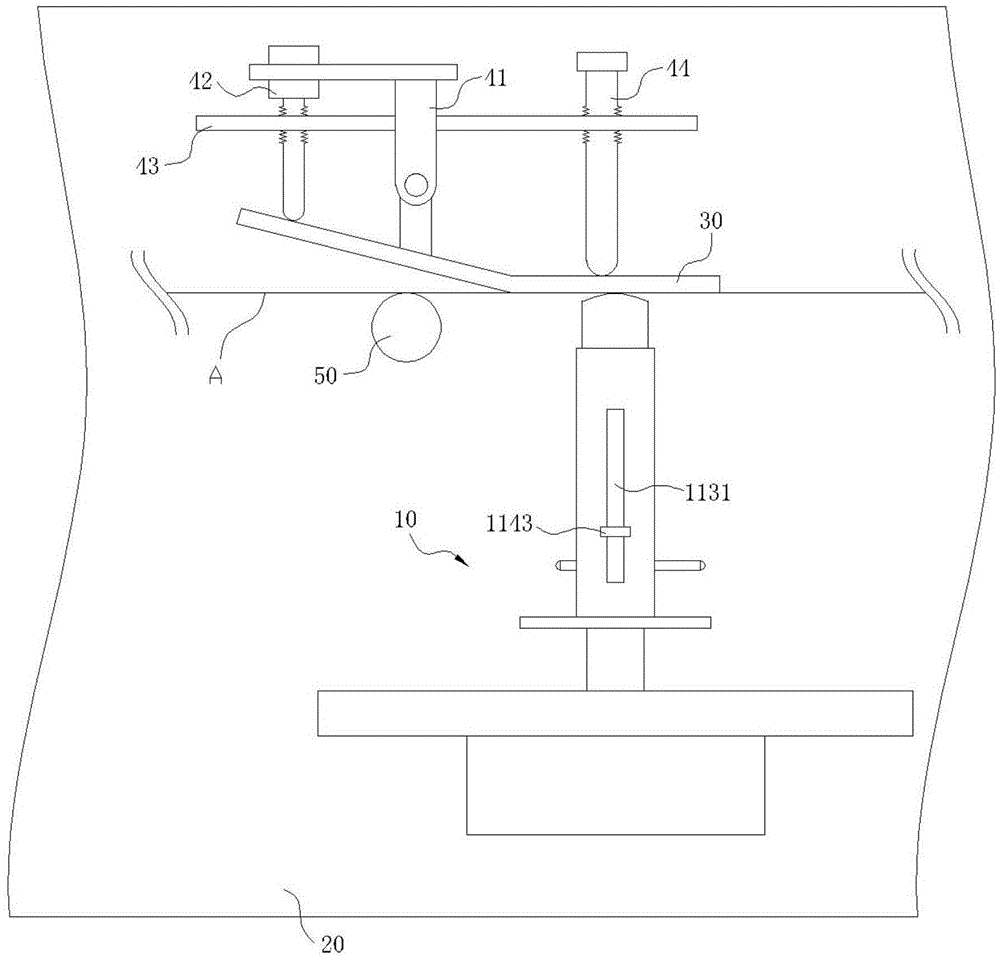

[0022] Such as Figure 1~3 As shown, a waxing device that can make the wax block close to the yarn includes a waxing machine 10, a fixing plate 20 for fixing the waxing machine 10, a V-shaped pressing plate 30, and a hinge device installed in the middle of the pressing plate 30 41. An adjustment component 42 connected to the hinge device 41 and located at one end of the pressure plate 30 , a base plate 43 for installing the adjustment component 42 , an adjustment component installed on the base plate 43 and located at the other end of the pressure plate 30 44 , the adjusting member 42 and the adjusting member 44 are screwed to the base plate 43 , and the pressing plate 30 is located on the top of the waxing machine 10 . Also includes a guide wheel 50, the guide wheel 50 is located at one side of the waxing machine 10, and the guide wheel 50 is located at the non-waxed side of the yarn A.

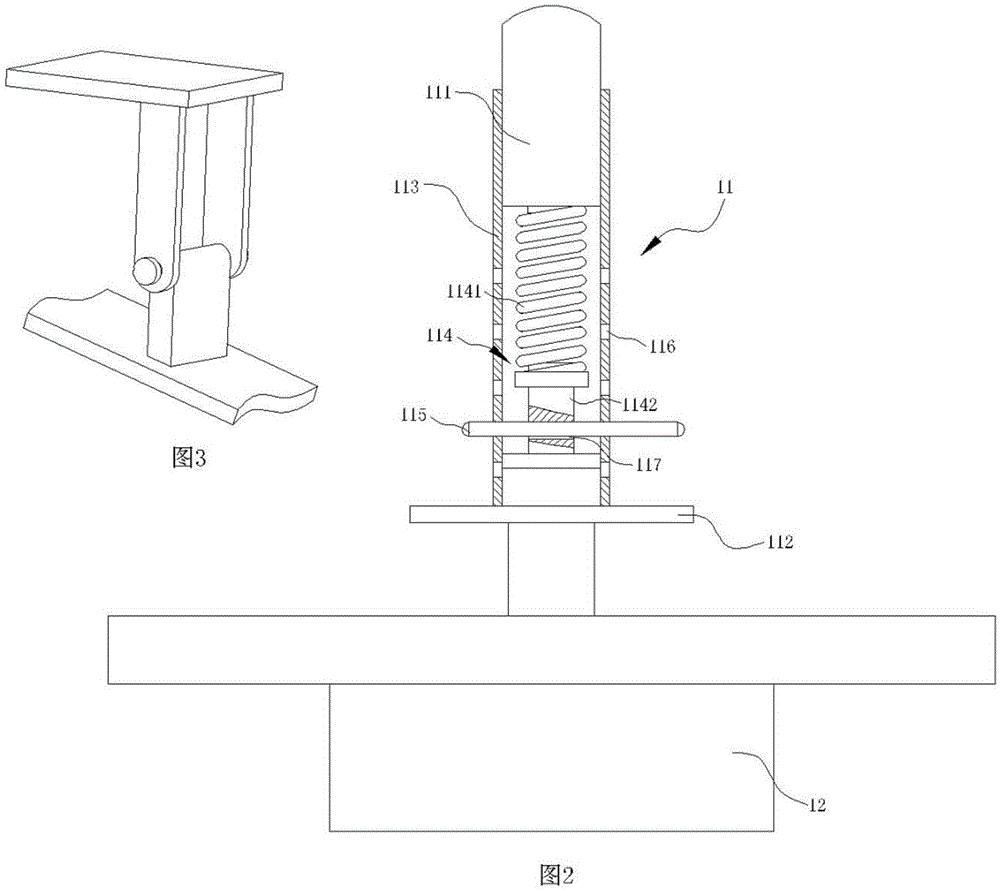

[0023] The waxing machine 10 includes a wax block device 11 and a transmission device 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com