Double-needle single-shuttle type sewing machine

A sewing machine and single-shuttle technology, which is applied in the direction of sewing machine components, sewing machine needle holders, sewing equipment, etc., can solve the problems of loose sewing, chain stitching is not particularly strong, and difficult to meet the needs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

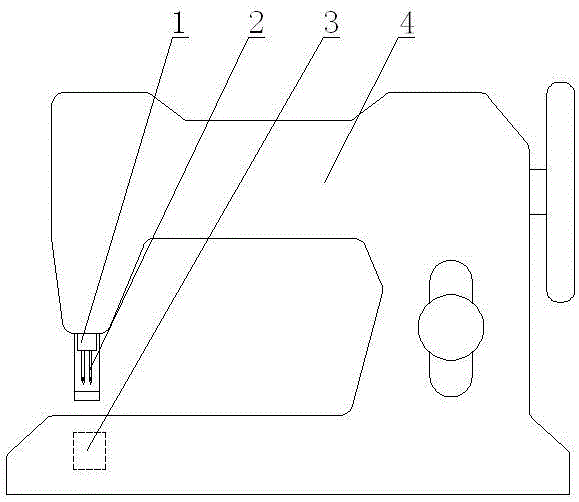

[0015] As shown in the figure, two sewing needles 2 fixed on the needle bar 1 of the sewing machine 4 are distributed in parallel, and the needle bar 1 moves up and down by manpower or motor through a series of gears and cams. Shuttle hook and bobbin assembly 3 are arranged at the bottom of sewing machine 4, and the quantity of shuttle hook and bobbin assembly 3 in sewing machine 4 is 1; Thread; driven by the mechanical mechanism, it rotates synchronously with the movement of the needle bar 1; when sewing, two parallel sutures will be formed on one side of the fabric, and a 2-in-1 chain of sutures will be formed on the other side of the fabric suture.

[0016] When sewing, the sewing needle of the sewing machine partially passes through the fabric, and two needles pass through the fabric at the same time to pull out two loops. A shuttle hook and bobbin assembly catches the loop before the needle is pulled out, it moves synchronously with the needle, once the needle is pulled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com