A heat absorber particle insulation method and device for tower-type solar thermal power generation

A tower type solar energy and heat sink technology is applied in the field of solar power generation to achieve the effects of reducing thermal fatigue, reducing temperature fluctuation and preventing solidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

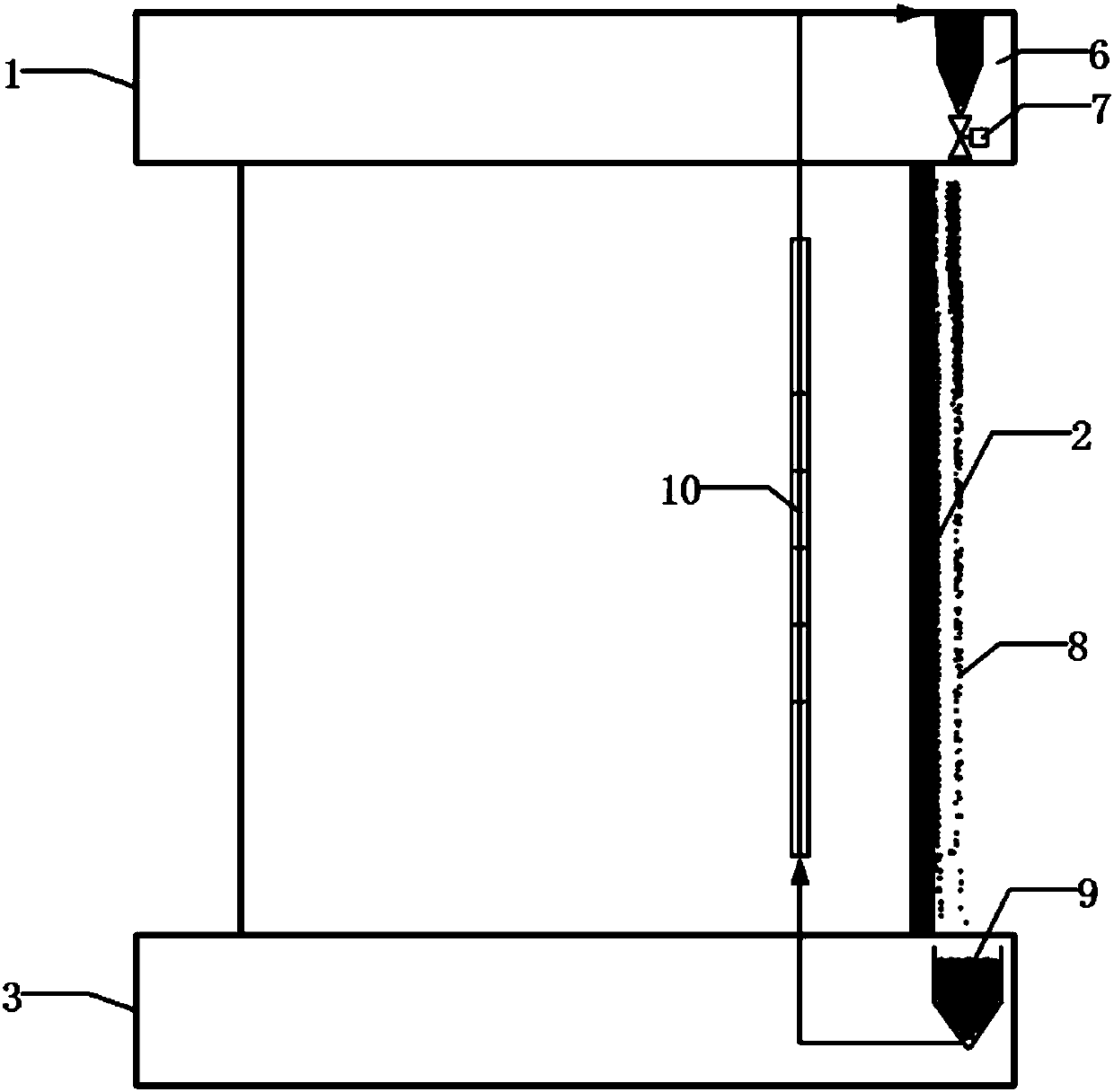

[0026] Such as figure 1 As shown, the heat absorber is surrounded by a plurality of heat absorbing tubes 2 arranged in a cylindrical shape, and the outer surface of the heat absorbing tubes is the outer wall of the heat absorber. The outer wall of the heat absorber receives solar radiation, converts the solar radiation into heat energy, and transmits it to the working medium in the heat absorbing pipe 2 to increase the temperature of the working medium. There are upper and lower heat preservation covers 1 and lower heat preservation covers on the upper and lower sides of the heat absorber. 3. In this embodiment, the magnetic effect is used to make the particles cover the surface of the heat absorber, which can reduce the external heat dissipation of the tube wall and reduce its temperature fluctuation when cloud shielding occurs.

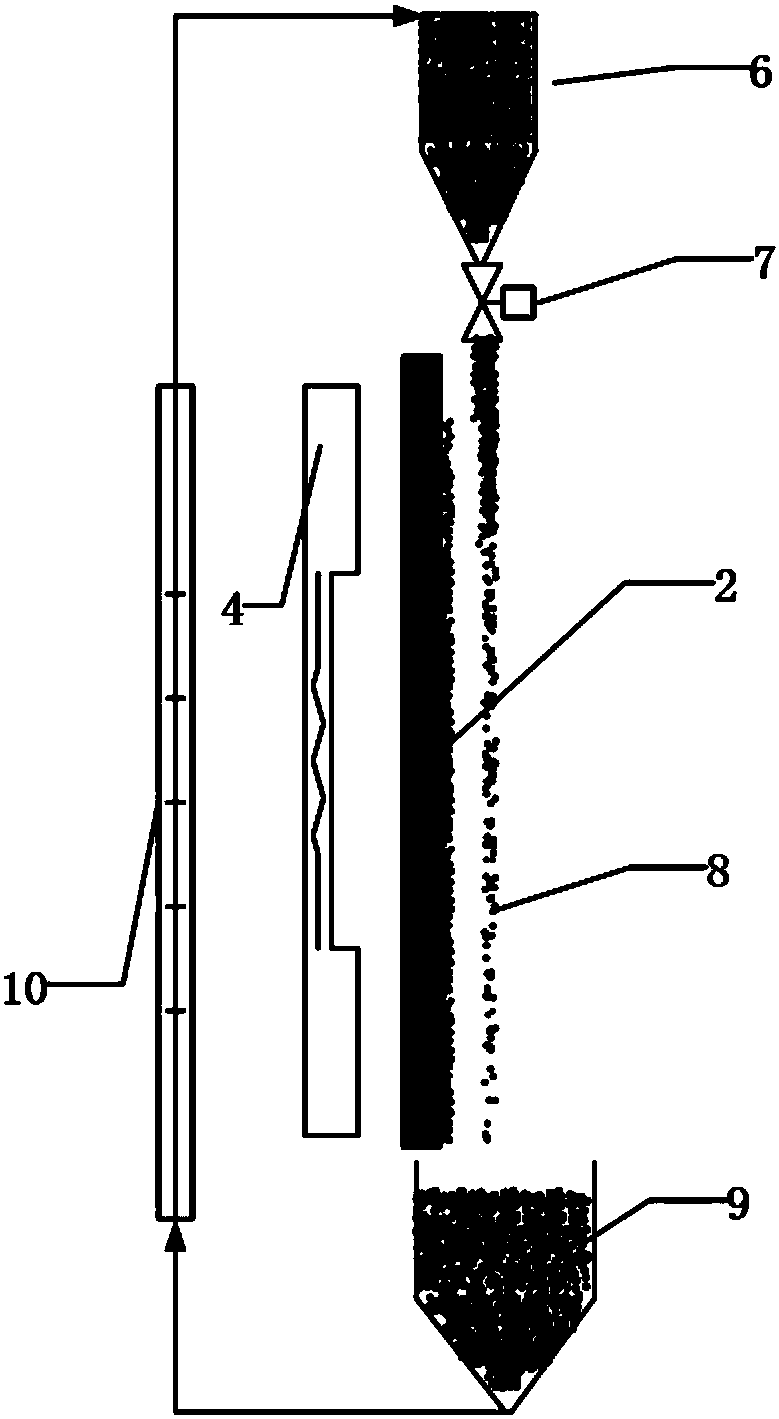

[0027] Such as figure 2 As shown, this embodiment uses magnetic action to cover the particles on the surface of the heat absorber. Since the de...

Embodiment approach 2

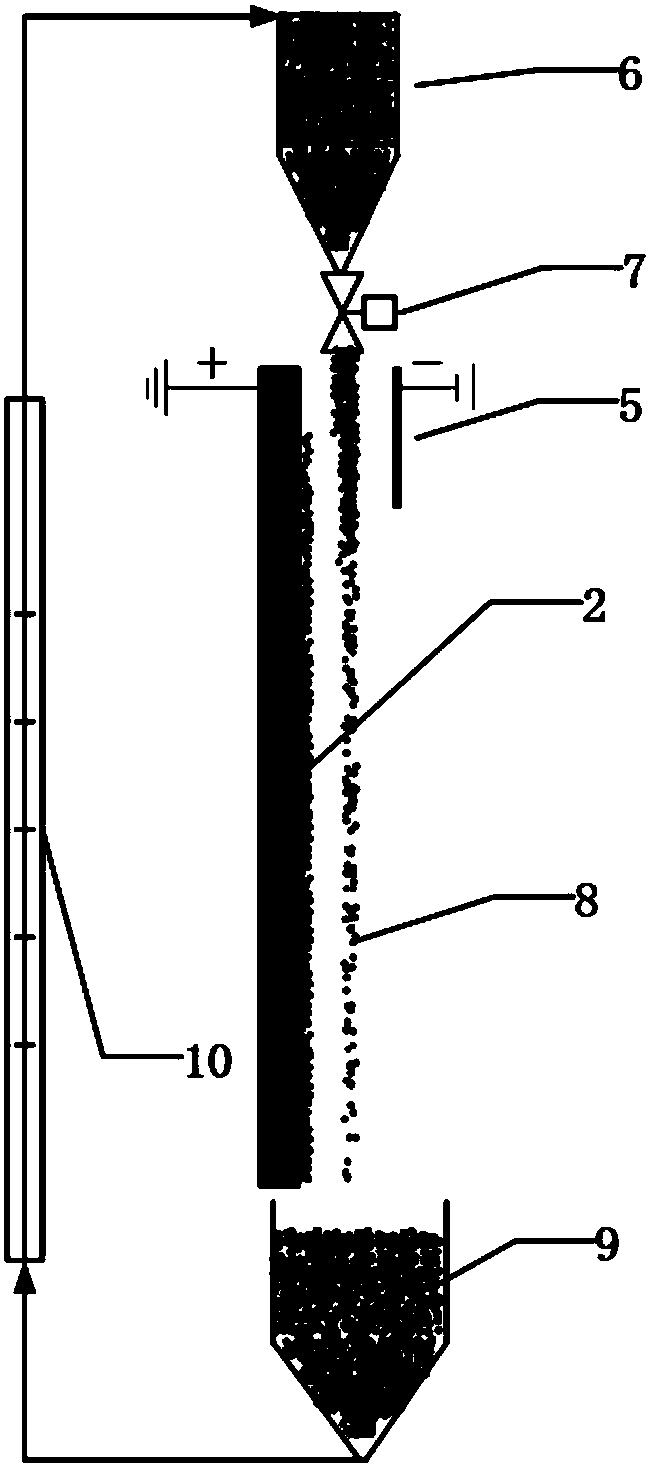

[0032] Such as image 3 As shown, in this embodiment, electric action is used to cover the particles on the surface of the heat absorber. When cloud occlusion occurs, the valve 7 is opened and the particles 8 fall from the particle upper tank 6 . A high-voltage electric field area is formed between the heat-absorbing tube 2 and the cathode line 5, the cathode line is the negative pole, and the heat-absorbing tube is the positive pole and grounded to form a corona discharge. The falling particles 8 are charged when they enter the electric field area, and cover the outer wall of the heat absorbing pipe 2 under the action of the electric field force during the falling process, forming a layer of particle insulation to reduce the external heat loss of the heat absorber.

[0033] When the cloud obscuration disappears and the applied electric field is withdrawn, the particles fall under the action of gravity or under the flapping vibration of the external force applied by the heat ...

Embodiment approach 3

[0036] Such as Figure 4 As shown, in this embodiment, gravity is used to cover the particles on the surface of the heat absorber. Fins are used as an auxiliary structure. When cloud occlusion occurs, the valve 7 is opened, and the particles 8 fall from the particle upper storage tank 6 . Because the fins 11 act on the outer wall of the heat-absorbing pipe with a specific shape and structure. The falling particles 8 are diverted through the diversion baffle 12. During the falling process, under the mechanical action of the fins 11, they cover the outer wall of the heat absorbing pipe 2 to form a layer of particle insulation to reduce the external heat loss of the heat absorber.

[0037]When the cloud obscuration disappears, the particles fall under the flapping vibration exerted by the external force on the heat sink. The dropped particles are collected in the lower particle storage tank 9, and are returned to the particle upper storage tank 6 through the particle conveying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com