A Treatment Method for Preventing Fracture Melting of Tensile Specimen

A technology for tensile specimens and processing methods, applied in the direction of applying stable tension/pressure to test material strength, measuring devices, instruments, etc., can solve the problems of increased test cost, test failure, port melting, etc., and achieve improved test success High efficiency, easy operation, and the effect of preventing instant breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

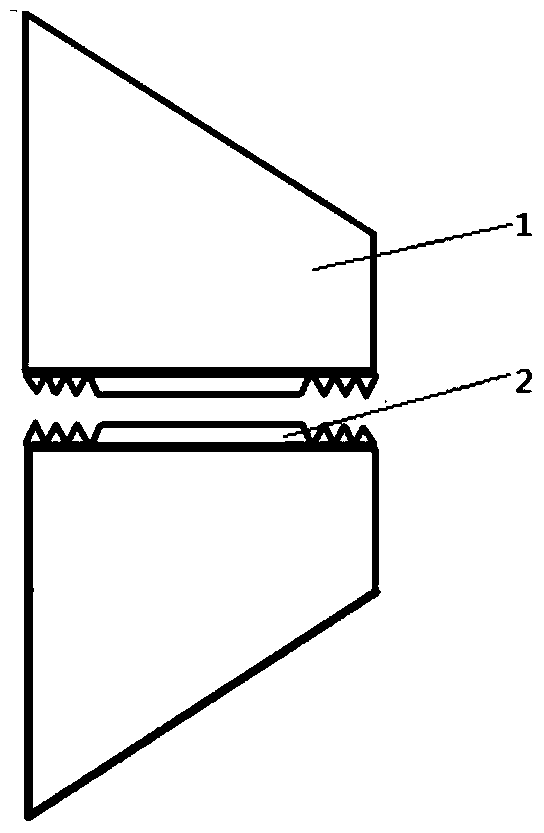

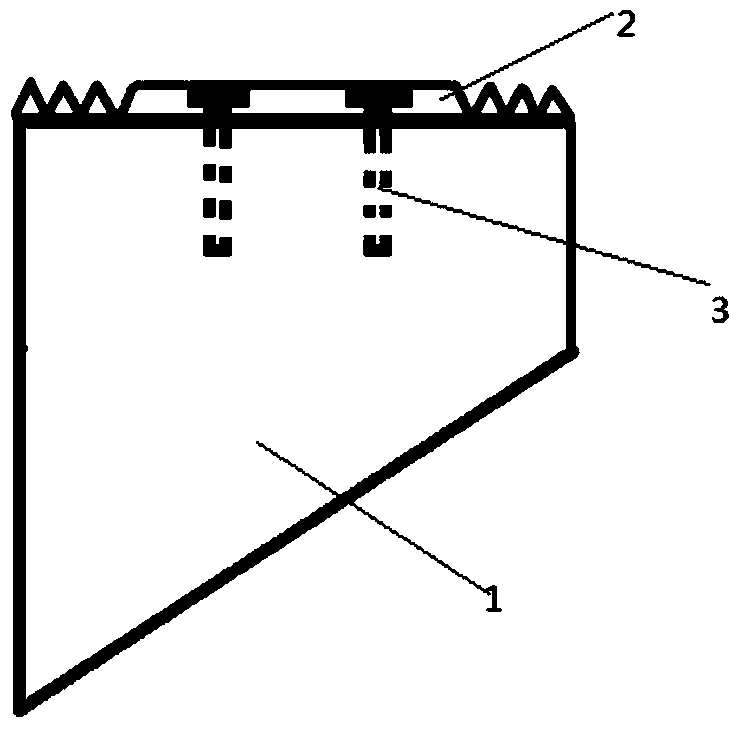

[0026] The thermal simulation testing machine model that the present invention adopts is Gleeble1500D. Carry out the Q235B strip high-temperature tensile test on the thermal simulation testing machine, weld the thermocouple wire on the sample according to the test requirements, and protect the thermocouple wire with a quartz tube, select the serrated clip 2 that matches the size of the sample, and insert the The serrated clip 2 is tightened on the trapezoidal block 1 with the screw 3, and the sample is clamped on the fixture. The temperature of the sample is raised to 1200°C at 10°C / s, kept for 5 minutes, and cooled to 1000°C at 5°C / s. Keep warm at 1000°C for 10 minutes, stop vacuuming, open the inlet valve of the sample chamber to fill helium, control the flow rate to 3 liters / hour, and the sample begins to stretch (strain rate =1×10 -3 / s), when the power angle (power angle) fluctuation range Δ (powerangle) > 30°, manually stop the thermal heating button, and manually cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com