Reliability detection method of direct-current transmission converter valve trigger monitoring unit

A detection method and DC transmission technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve problems such as thyristor-level faults, tripping and power outage maintenance, and board failures, etc., to achieve high reliability, improve safety, and reduce The effect of the risk of electric shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

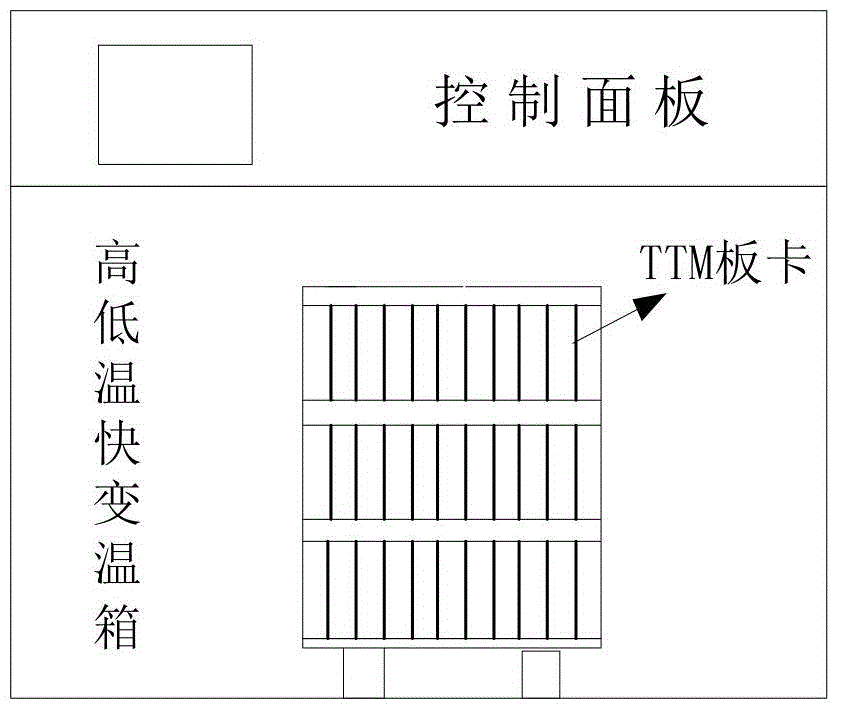

[0032] The present invention has been successfully applied in many domestic UHV DC transmission projects. According to the size of the actual engineering quantity, construction period requirements and actual equipment conditions, the number of boards for each batch of environmental stress detection is reasonably configured. Usually, 3 environments are used. The inspection box can complete the failure and screening inspection of all TTM boards in each batch, and can simultaneously perform functional inspection and visual inspection. like image 3 and 4 Shown are the front and side views of the layout of the TTM board in the environmental test box. There is an air duct between batches of TTM boards.

[0033] After adopting this method, after statistics, the unit has produced more than 4,000 TTM boards in total, and no TTM board was found to be invalid in the engineering site inspection before it was put into operation after leaving the factory. Therefore, it is believed that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com