Coaxial Cable Connectors with Improved Crimp Strength and Impedance Performance

A coaxial cable and connector technology, which is applied in the direction of conductive connection, connection, two-part connection device, etc., can solve the problems of impedance disorder and insufficient improvement of friction force, and achieve the effect of improving crimping strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] A preferred embodiment of the present invention will be described with reference to the drawings. In addition, here, a so-called right angle type connector will be described, but the present invention is not limited thereto.

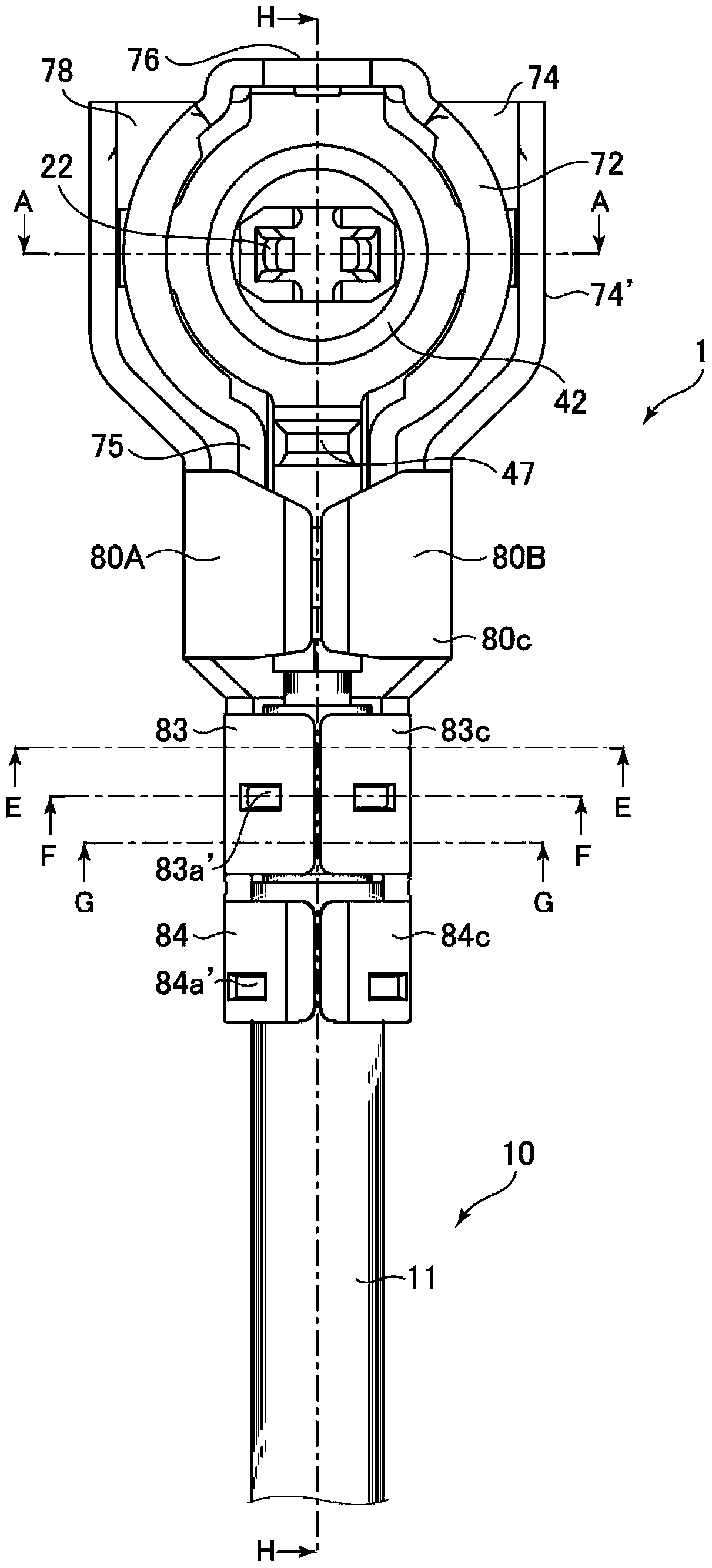

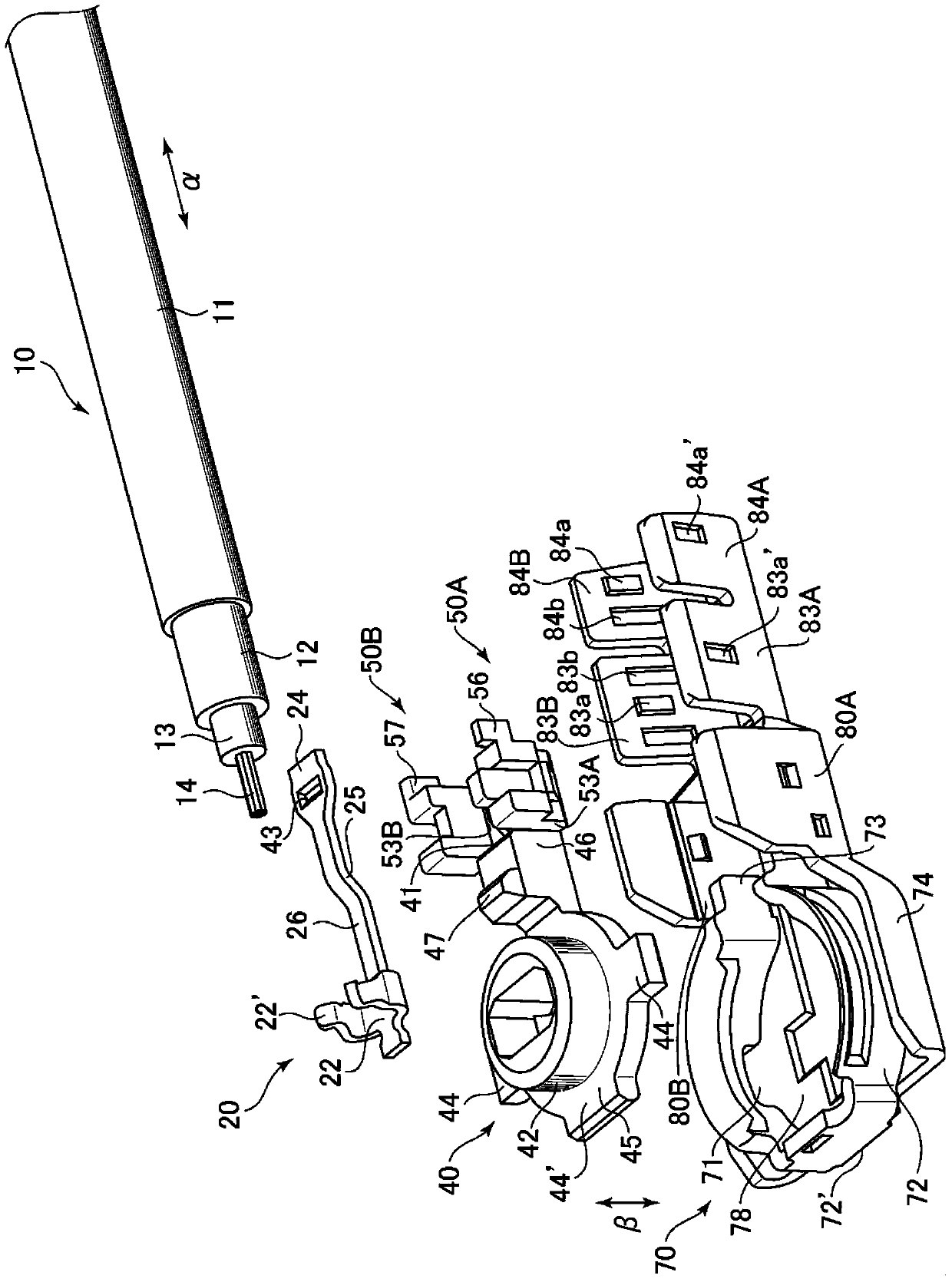

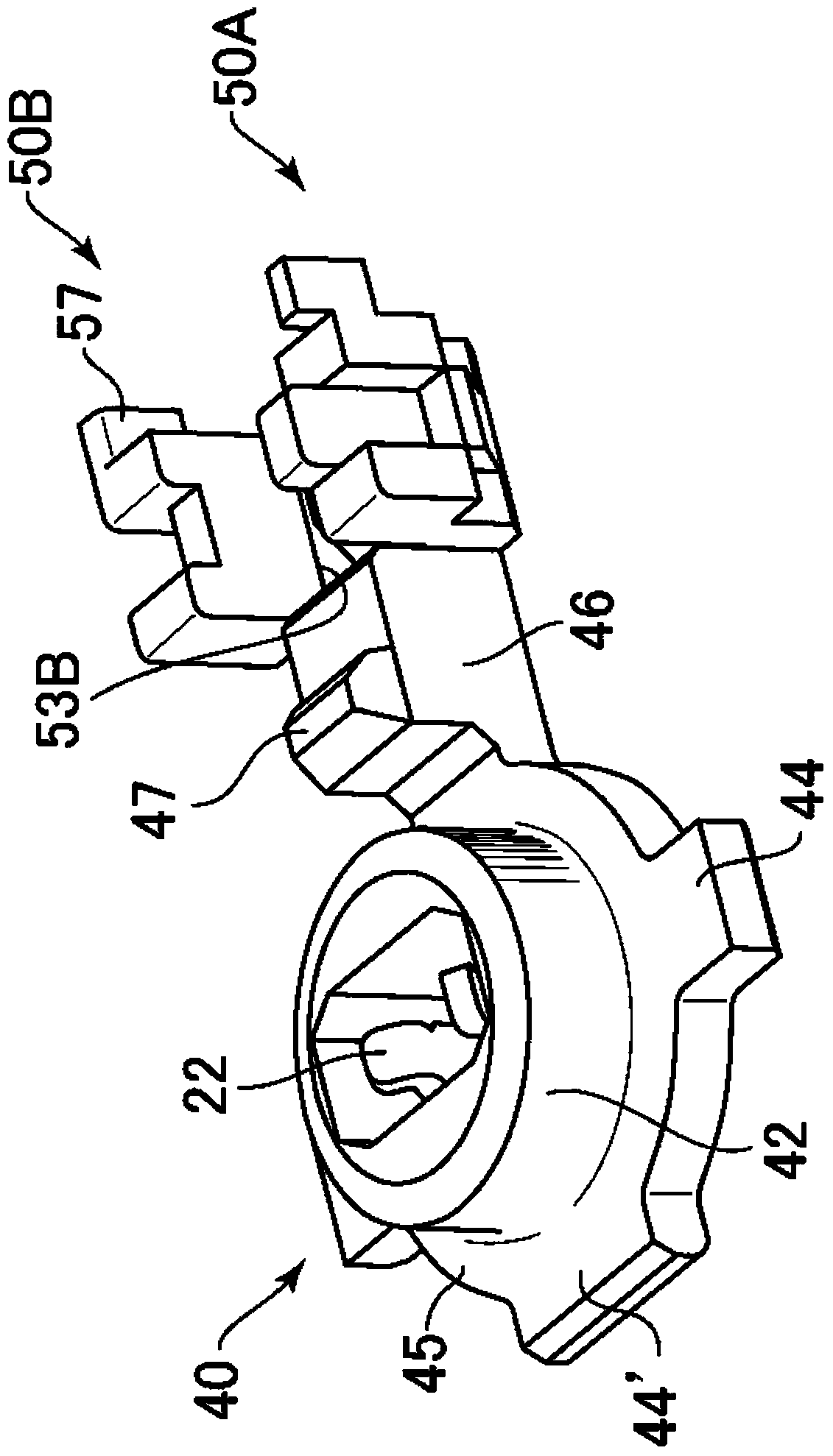

[0062] figure 1 is a bottom side plan view of the coaxial cable connector 1 of the present invention connected to the coaxial cable 10, figure 2 is an exploded perspective view of the coaxial cable connector 1 . Coaxial cable connector 1 separated by figure 1 The central axis of H-H is a left-right symmetrical shape, which mainly includes: a conductive terminal 20; an insulating shell 40, the shell 40 is integrally formed with the terminal 20; and an outer conductor housing 70, the outer conductor housing 70 covers At least a portion of the housing 40 and at least a portion of the coaxial cable 10 . In addition, since the terminal 20 and the housing 40 are integrally formed, they cannot actually be disassembled, but in figure 2 In FIG. 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com