An easy-to-replace pressing plate assembly for a vertical slotting machine and its replacement method

A vertical slotting machine and pressing plate technology, which is applied to metal processing machinery parts, manufacturing tools, positioning devices, etc., can solve problems such as inability to disassemble and replace parts, poor tightness of crimping, and increased crimping strength, etc., to achieve Small gap, high crimping strength, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

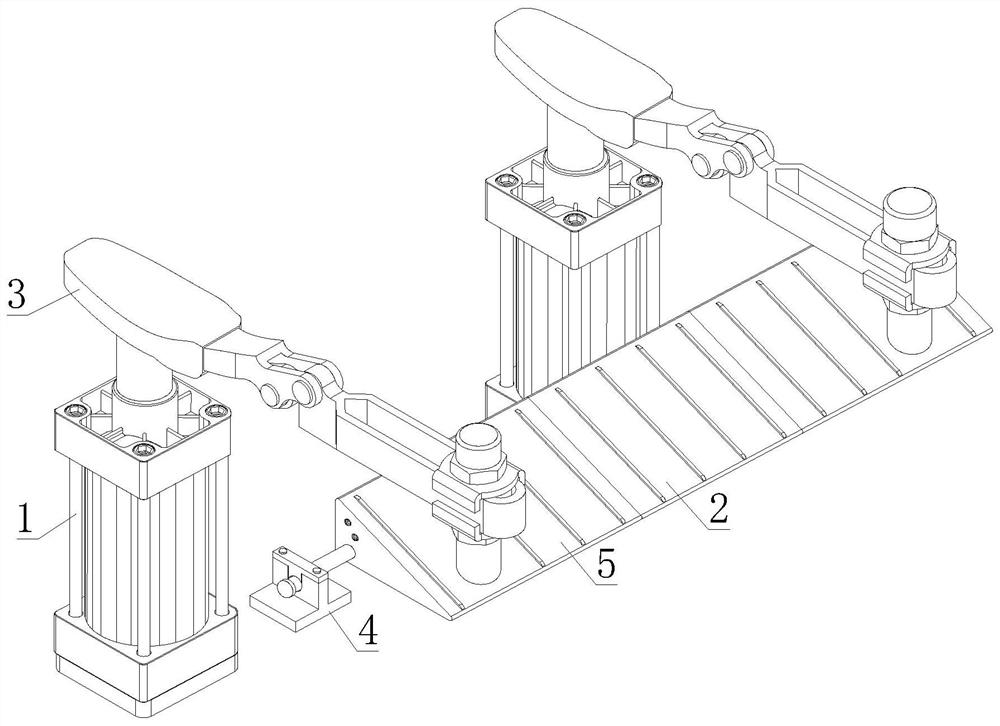

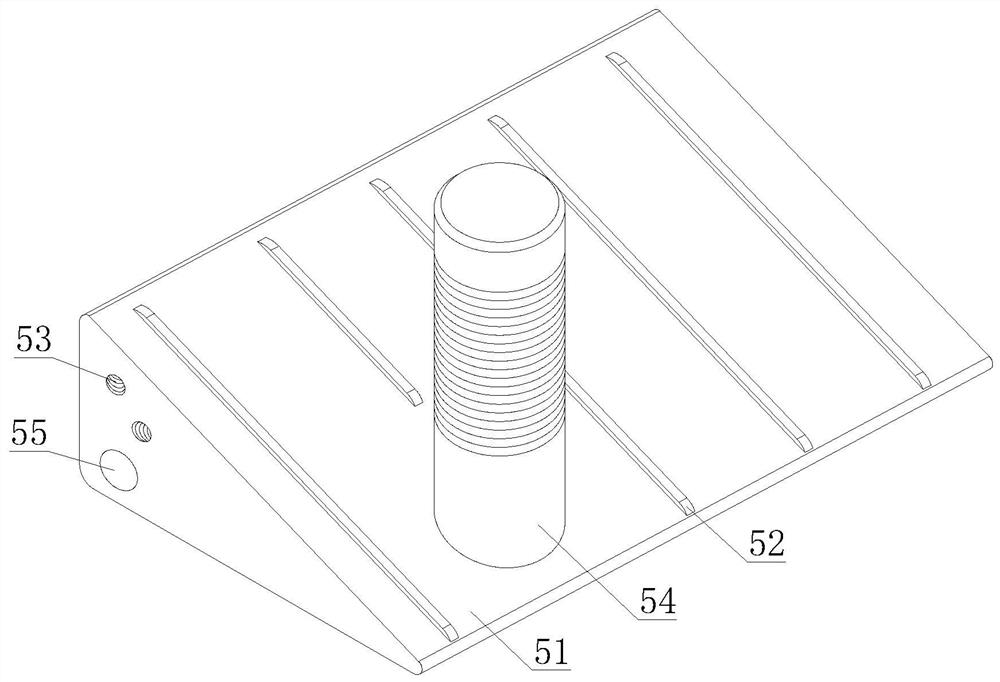

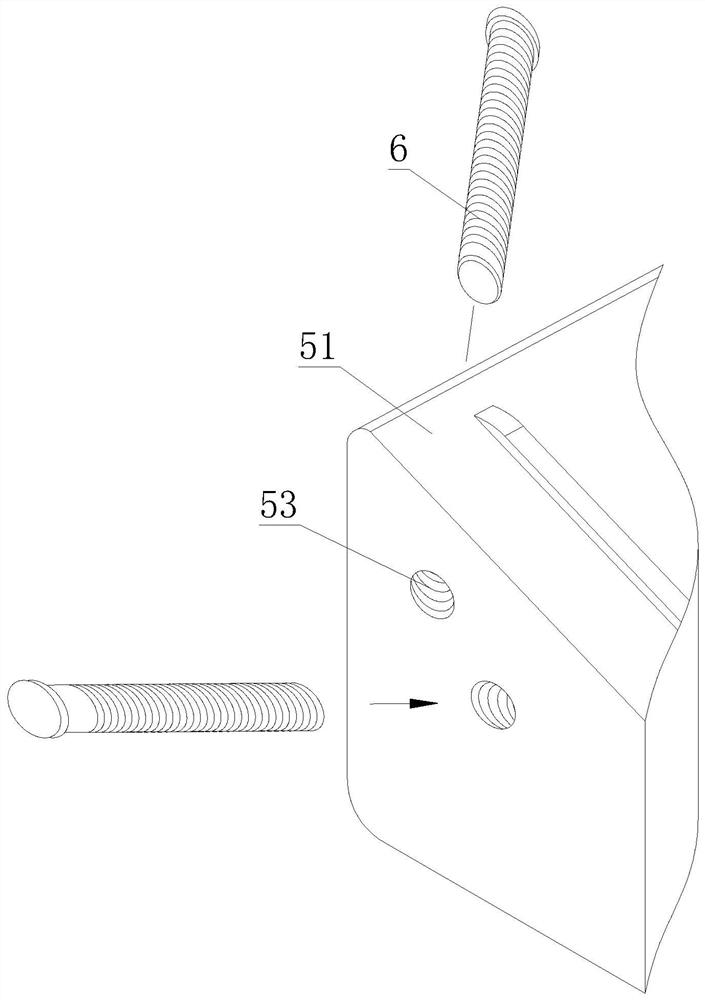

[0028] refer to figure 1 , an easy-to-replace platen assembly for a vertical slotting machine proposed by the present invention, comprising a cylinder 1, a main platen mechanism 2, a cylinder connection mechanism 3, a platen fixing mechanism 4 and an auxiliary platen mechanism 5, and the upper end of the cylinder 1 is hinged with a cylinder The connection mechanism 3, the front end of the cylinder connection mechanism 3 is connected with the main pressure plate mechanism 2, and the auxiliary pressure plate mechanism 5 is fixedly connected between the two main pressure plate mechanisms 2 through oblique bolts 6. There is at least one auxiliary pressure plate mechanism 5, and the main pressure plate Mechanism 2 and auxiliary platen mechanism 5 are rotatably connected to platen fixing mechanism 4, cylinder assembly 1 is installed on the beam of the vertical slotting machine, platen fixing mechanism 4 is fixed on the operating table of the vertical slotting machine by bolts, cylind...

Embodiment 2

[0033] refer to Figure 7 , an easy-to-replace platen assembly for a vertical slotting machine proposed by the present invention, comprising a cylinder 1, a main platen mechanism 2, a cylinder connection mechanism 3, a platen fixing mechanism 4 and an auxiliary platen mechanism 5, and the upper end of the cylinder 1 is hinged with a cylinder The connection mechanism 3, the front end of the cylinder connection mechanism 3 is connected with the main pressure plate mechanism 2, and the auxiliary pressure plate mechanism 5 is fixedly connected between the two main pressure plate mechanisms 2 through oblique bolts 6. There is at least one auxiliary pressure plate mechanism 5, and the main pressure plate The mechanism 2 and the auxiliary platen mechanism 5 are rotatably connected to the platen fixing mechanism 4. The cylinder assembly 1 is installed on the beam of the vertical slotting machine, and the platen fixing mechanism 4 is fixed on the operating table of the vertical slotting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com