Fully press-fit packaged high-voltage semiconductor devices

A semiconductor and high-voltage technology, which is applied in the field of high-voltage semiconductor devices with full crimping packaging, can solve the problem that the chip reliability cannot meet the high-voltage products and high-current products, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

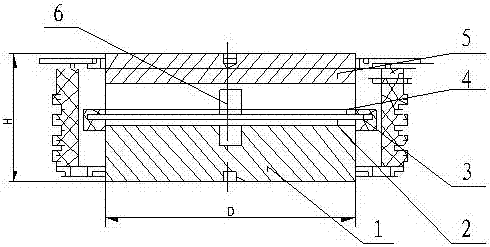

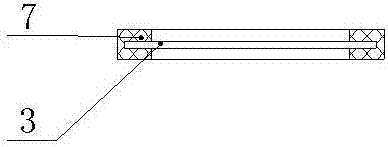

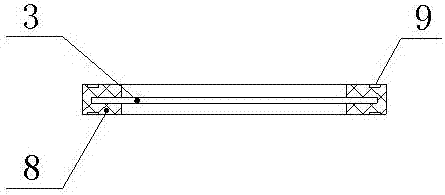

[0024] Combine below Figure 1 to Figure 5 The present invention is further described.

[0025] Such as figure 1 shown. High-voltage semiconductor devices are fully crimped and packaged, and the lower sealing part 1 of the tube case, the lower molybdenum wafer 2, the semiconductor chip 3, the upper molybdenum wafer 4, the gate lead assembly 6, and the upper sealing part 5 of the tube case are packaged by cold pressure made. Install the gate lead assembly 6 in the center opening of the upper sealing part 5 of the tube case, the gate lead assembly 6 is higher than the surface of the upper sealing part 5 of the tube case, and snap into the center through hole of the upper molybdenum disc 4, and position the upper molybdenum disc . The diameter D of the device table is: 23mm≤D≤140mm, and the thickness H of the tube shell is: 23mm≤H≤40mm. The internal semiconductor chip 3 of the device and the upper and lower molybdenum wafers 2, 4 and the upper and lower sealing parts 1, 5 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com