Compressor and manufacture method thereof

A technology for compressors and metal gaskets, applied in the field of compressors, can solve problems such as classification difficulties, unusable asbestos materials, difficulties, etc., and achieve the effects of easy replacement and maintenance, increased surface pressure, and guaranteed sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

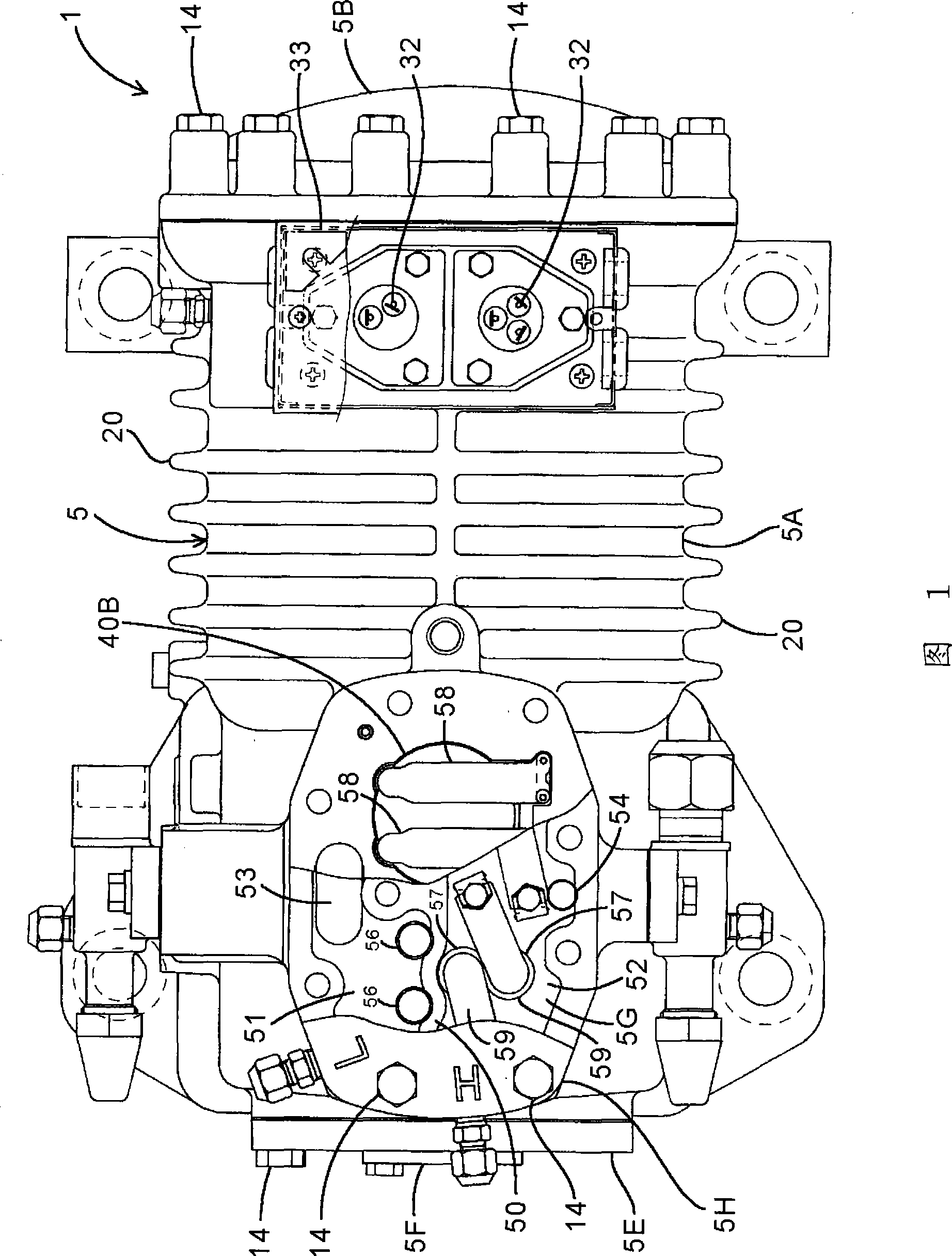

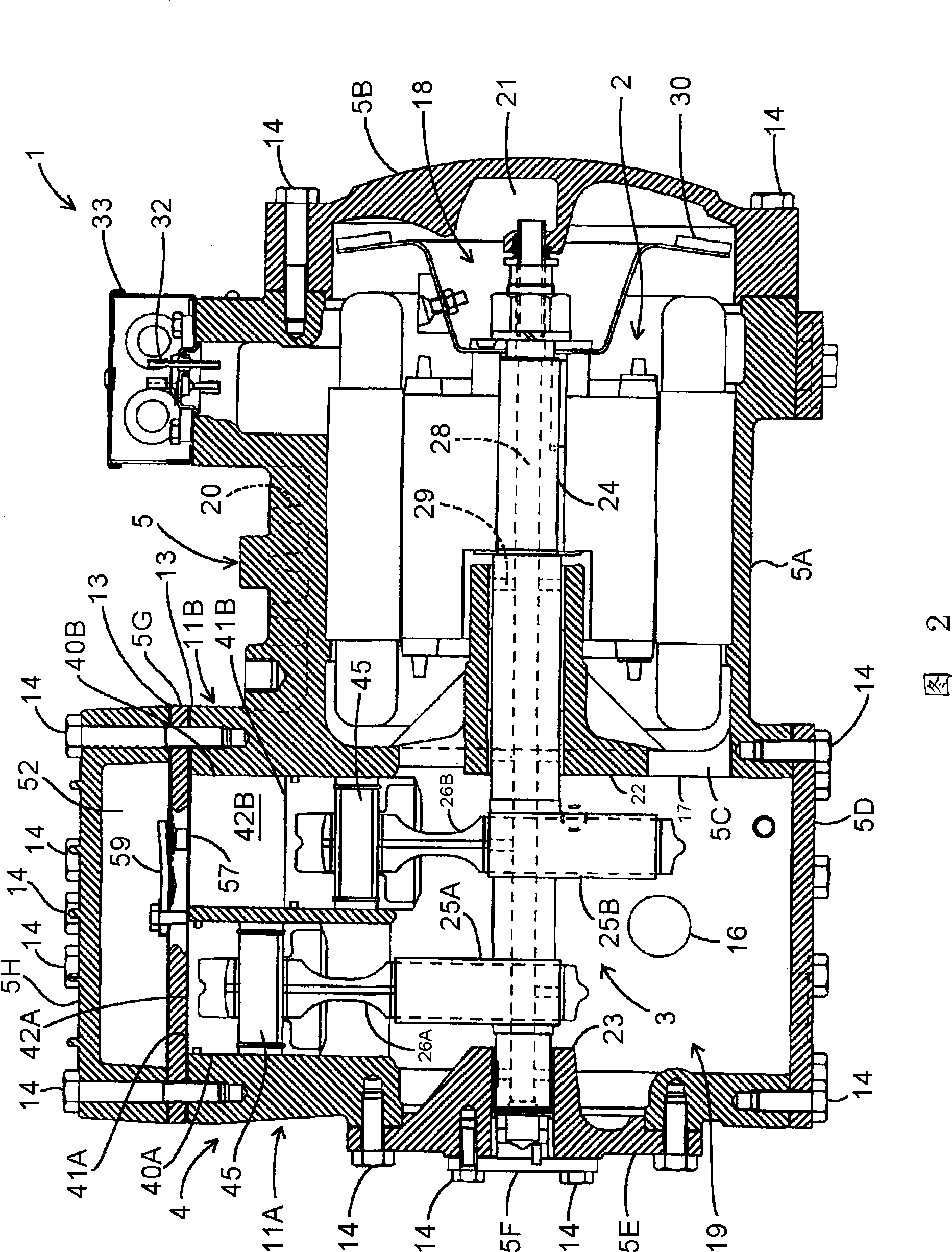

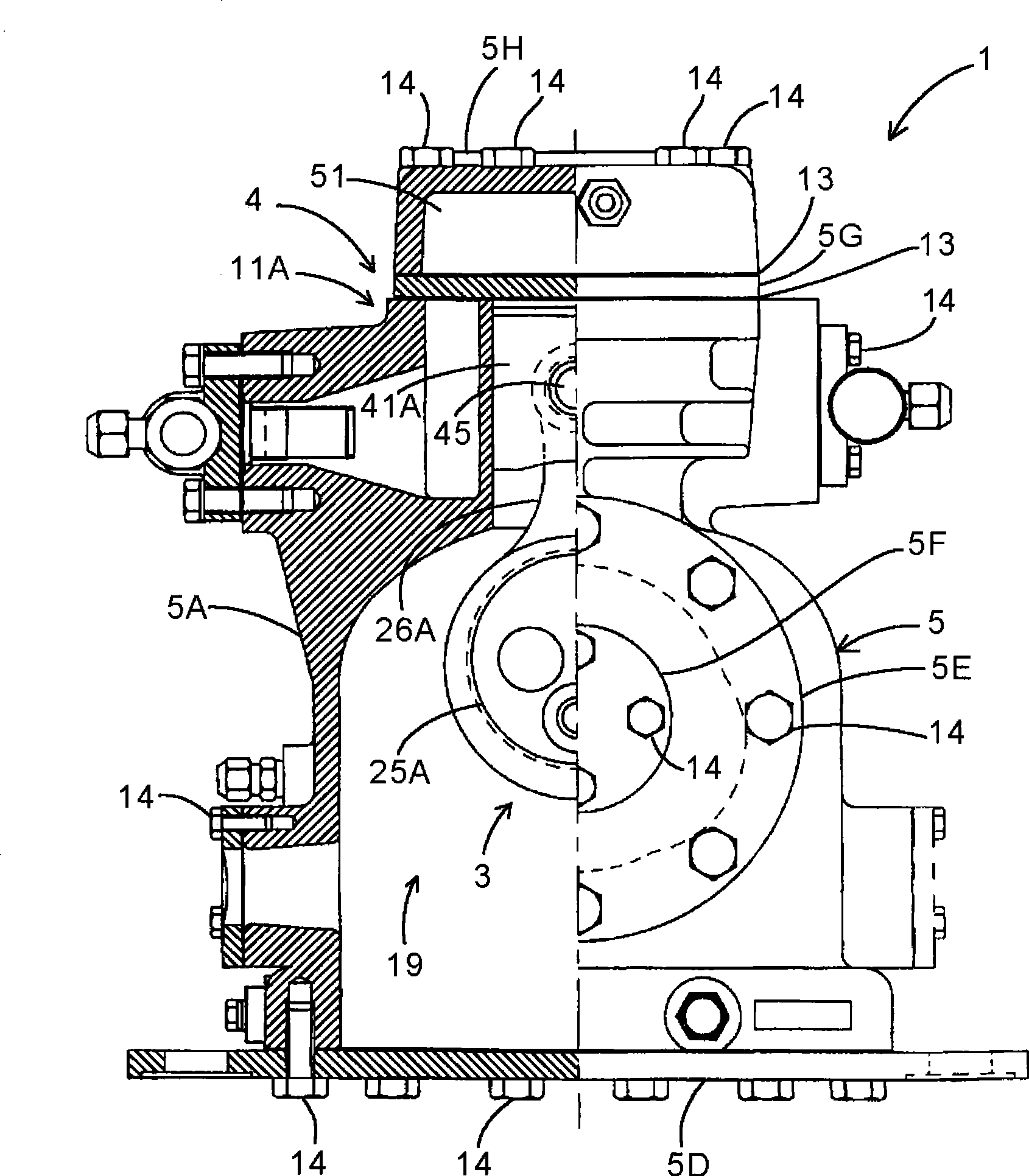

[0040] Fig. 1 is a top view of a semi-hermetic compressor 1 applicable to an embodiment of the present invention, and Fig. 2 is a longitudinal sectional front view of the compressor 1, image 3 is a partial longitudinal sectional side view of the compressor 1, and FIG. 4 is an exploded longitudinal sectional front view of the compressor 1, Figure 5 It is an exploded partial longitudinal sectional side view of the compressor 1, FIG. 6 is a top view of the first metal gasket 13A installed on the compressor 1, and FIG. 11 is a top view of the second metal gasket 13B installed on the compressor 1. .

[0041] The compressor 1 of the embodiment is composed of an electric motor (driving element) 2, a power conversion member 3, a compression member 4, and a housing 5 for accommodating them. The motor 2 generates rotational power, and the power conversion member 3 converts Rotational power is converted into reciprocating power, and the compression unit 4 is driven by the reciprocating...

Embodiment 2

[0075] In addition, FIG. 12 is an exploded partial longitudinal sectional side view showing an example of a V-type 4-cylinder reciprocating semi-hermetic compressor 1 . At this time, four air cylinders 40 are formed on the casing main body 5A, and pistons 41 are accommodated in each. Furthermore, between the housing body 5A and the valve plate 5G of each cylinder head 5H, a packing 13 in which the same metal gaskets 13A and 13B as described above are stacked is provided. Even in such a V-type compressor 1, the present invention is effective.

[0076] In addition, in the above-mentioned embodiments, two metal gaskets (the first metal gasket 13A and the second metal gasket 13B) are stacked and arranged between the valve plate 5G and the housing main body 5A, but it is not limited thereto. , It is also possible to adjust the top gap by overlapping three or more metal spacers (including all of the same plate thickness or any one or all of the plate thicknesses are different). In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com