Environment-friendly cable pile

A cable pile, an environmentally friendly technology, applied in the field of environmental protection cable piles, can solve the problems of cement block structure falling off, vehicle damage, vehicle collision, etc., to achieve the effect of avoiding being hit, avoiding vehicle damage, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

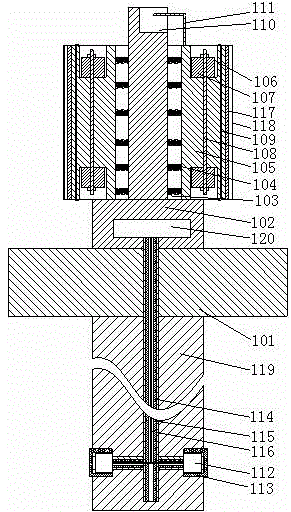

[0023] Such as figure 1 As shown, an environmentally friendly cable pile includes a base 101 and an internal pile body 102 arranged above the base. A stepped groove 103 is arranged on the outer wall of the upper end of the internal pile body, and the stepped groove at the upper end of the internal pile body An outer pile is sheathed on the outside, and the inner diameter of the outer pile is smaller than the outer diameter of the inner pile;

[0024] The external pile body is composed of two frame structures 105 with a semicircular cross section, the two frame structures form a hollow column structure, and the two frame structures face the interior A high-strength spring 104 is arranged on one end face of the pile body, and a draw-in groove 106 is respectively arranged on the upper and lower end faces of the two frame structures, and a buckle 107 is arranged in the draw-in groove, and the buckle is a ring structure;

[0025] A protective plate 117 is provided on the outer wa...

Embodiment 2

[0032] In this embodiment, on the basis of Embodiment 1, in order to determine whether there is a relative misalignment between the external pile body and the internal pile body after long-term use, in this embodiment, an intuitive observation structure is provided on the outside. Preferably, The upper end of the inner pile protrudes from the upper part of the outer pile, a groove 110 is arranged on one side of the inner pile, and a grid line is arranged on the inner wall of the groove. An L-shaped pointer 111 is arranged on the upper end surface of the external pile, the end of the pointer is located in the groove, and the axis of the external pile is parallel to the axis of the internal pile. When the pointer is located in the middle of the groove. When installing, make the pointer located in the middle of the groove. After using for a period of time, observe the position of the pointer. When the position of the pointer is observed to deviate on the grid line, it means that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com