Press type hairpin and manufacturing method thereof

A manufacturing method and push-type technology, applied in hairdressing equipment, hair curling or perming devices, clothing, etc., can solve problems such as difficult production efficiency and difficult to expect durability improvement, and achieve good wearing feeling, good decoration, Effect to prevent durable fall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

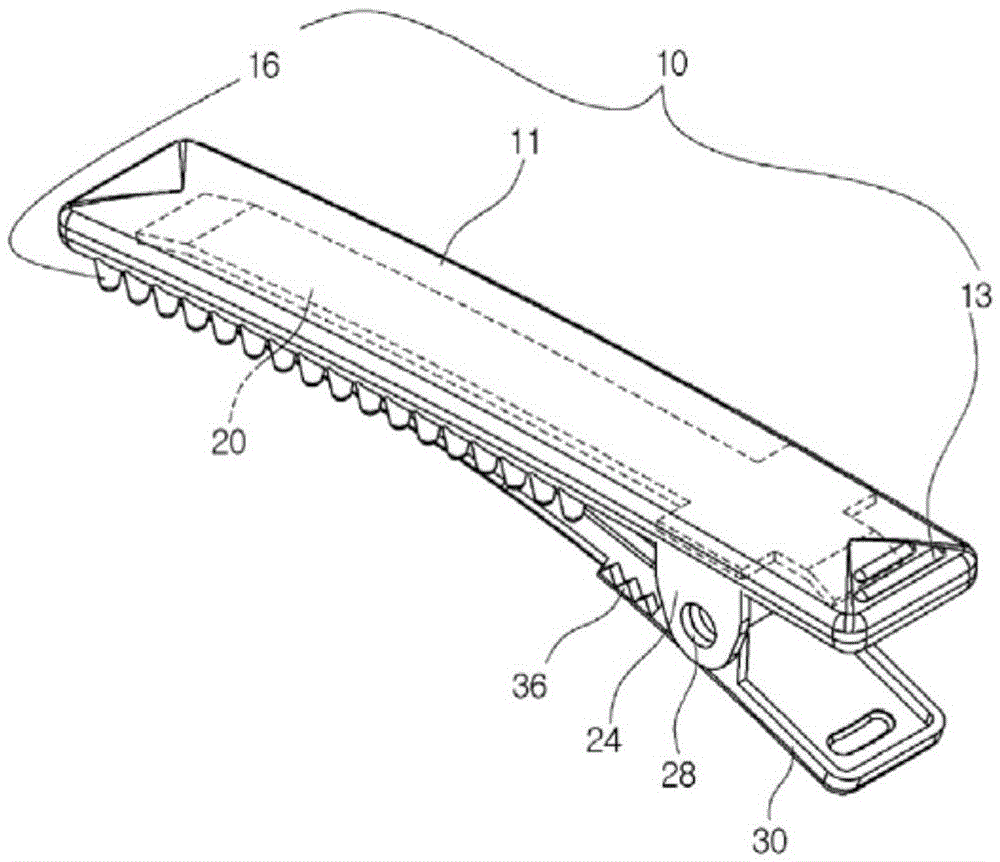

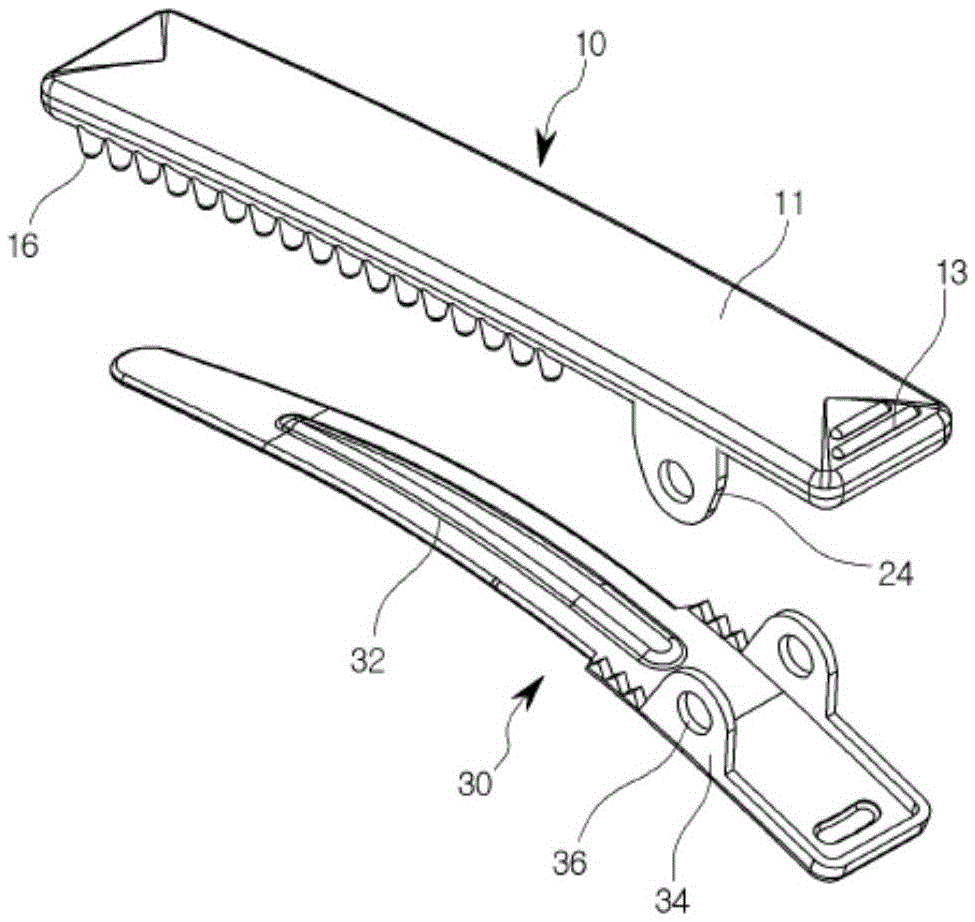

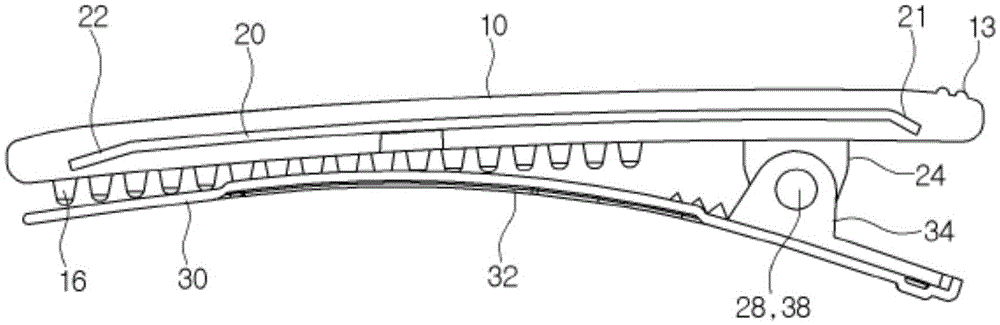

[0031] A push-type hair clip according to an embodiment of the present invention includes an upper component 10 , a metal sheet 20 , and a lower component 30 . The push-type hair clip refers to a shape suitable for bundling hair in small units, but is not necessarily limited thereto.

[0032] According to the present invention, the upper member 10 is formed of a resin material. The upper member 10 includes an outer surface 11 having a decorative pattern and a pressing portion 13 for hand pressing formed on an inner side end of the outer surface 11 . The inner end refers to the part that is pressed by hand, and the outer end refers to the part that can be expanded. In addition, a plurality of concavo-convex portions 16 are formed along a straight line on the inner surface of the upper member 10 to improve the holding power of the hair. The outer surface 11 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com