Movable type lamp holder glue drying device

A mobile, glue-baking technology, which is applied to the device for coating liquid on the surface, pre-treating the surface, coating, etc., can solve the problems of high investment cost, complicated operation, and low flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

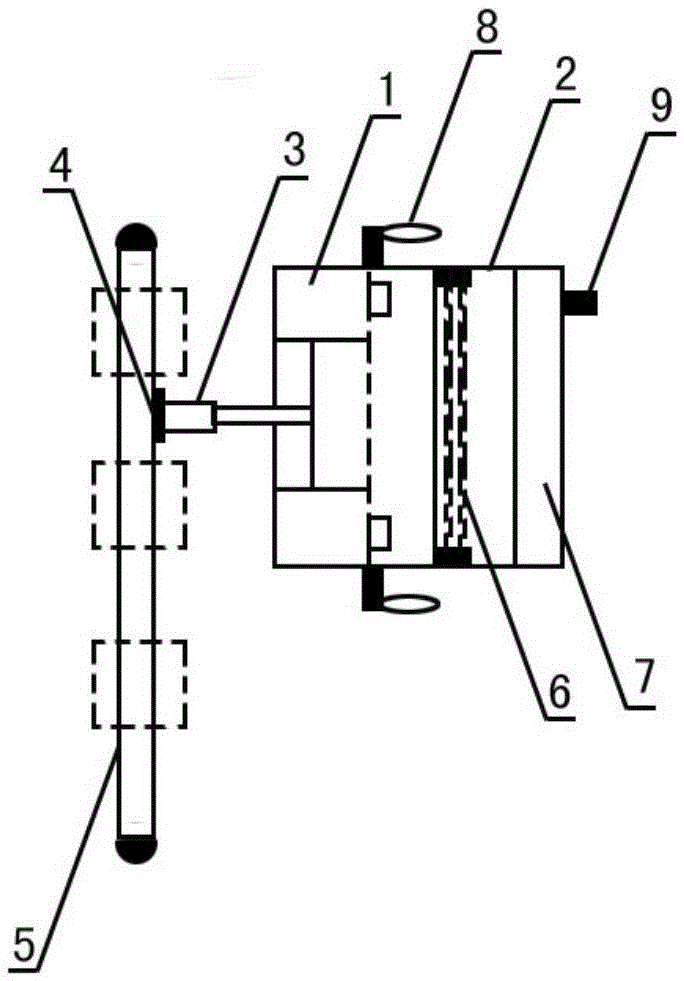

[0012] Embodiment: as shown in the accompanying drawing. A mobile lamp holder glue drying device, comprising a body (1), the outer side of the body (1) is provided with a cover device (2) with a side concave structure design, and the left side is provided with a telescopic rod device (3) and a movable module (4) It is connected and fixed to the bottom of the mobile device (5), and the electric heating plate device (6) and the temperature control device (7) are installed in the shell. When in use, it runs synchronously with the lamp holder glue filling machine, and moves after adjusting the corresponding angle through the turning device (8) Baking work.

[0013] A mobile lamp holder rubber drying device. A prompting device (9) is provided on the outside of a body (1), and the prompting information is displayed by sound or LED light.

[0014] A mobile lamp holder glue drying device, in which a temperature sensing module is arranged in a casing device (2) and connected to a temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com