Coke oven ascension pipe evaporator connecting structure and manufacturing method thereof

A technology of connection structure and production method, which is applied in the direction of coke oven, flange connection, heating of coke oven, etc., can solve the problems of damage, low sewage discharge efficiency, complicated sewage operation, etc., and achieves reduction in the number of sewage valves and easy sewage operation. , Reasonable effect of connection structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

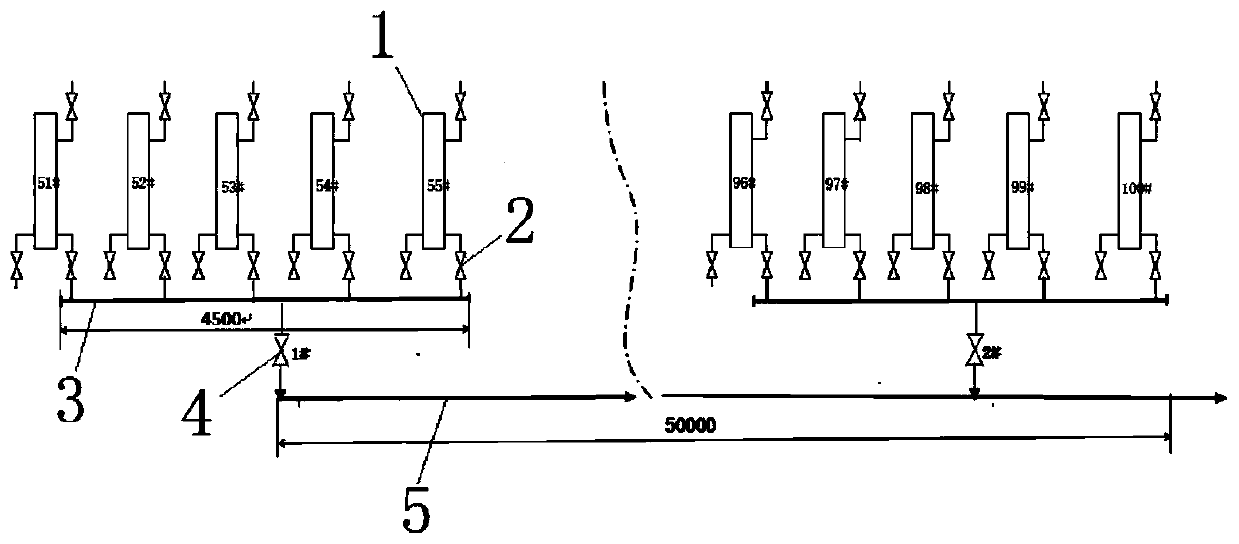

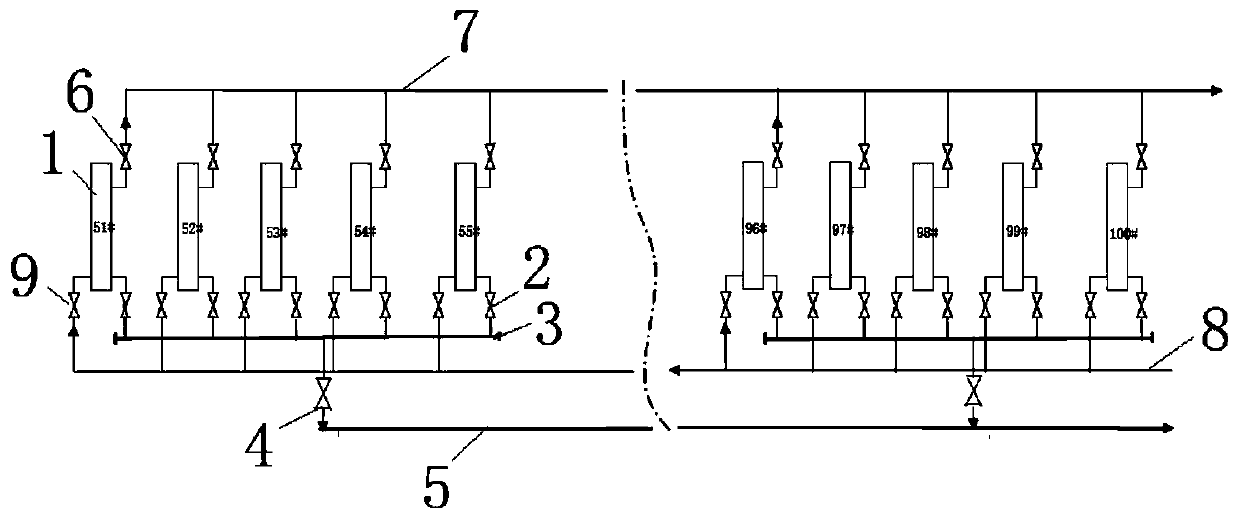

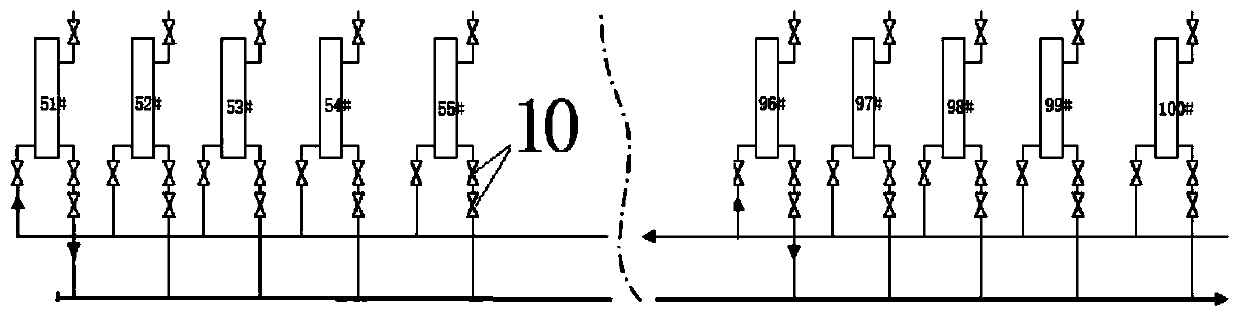

[0028] Such as figure 1 and figure 2 As shown, the connection structure of the coke oven riser evaporator includes a sewage discharge pipe 5, a blowdown valve 4, a group of riser evaporators 1 arranged side by side, a group of balance valves 2 and a communication pipe 3; several adjacent riser evaporators The riser evaporator 1 forms a riser evaporator interconnection unit, and all the riser evaporators in each riser evaporator interconnection unit are connected to the same communication pipe 3 through the corresponding balance valve 2, forming a group of riser evaporators arranged side by side. The interconnection unit of the evaporator; the communication pipes corresponding to the interconnection units of different riser pipe evaporators are connected to the sewage pipe 5 through the corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com