Axle suspension device

A suspension device, axle housing technology, applied in the direction of suspension, elastic suspension, transportation and packaging, etc., to achieve the effect of large height distance and low steering force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

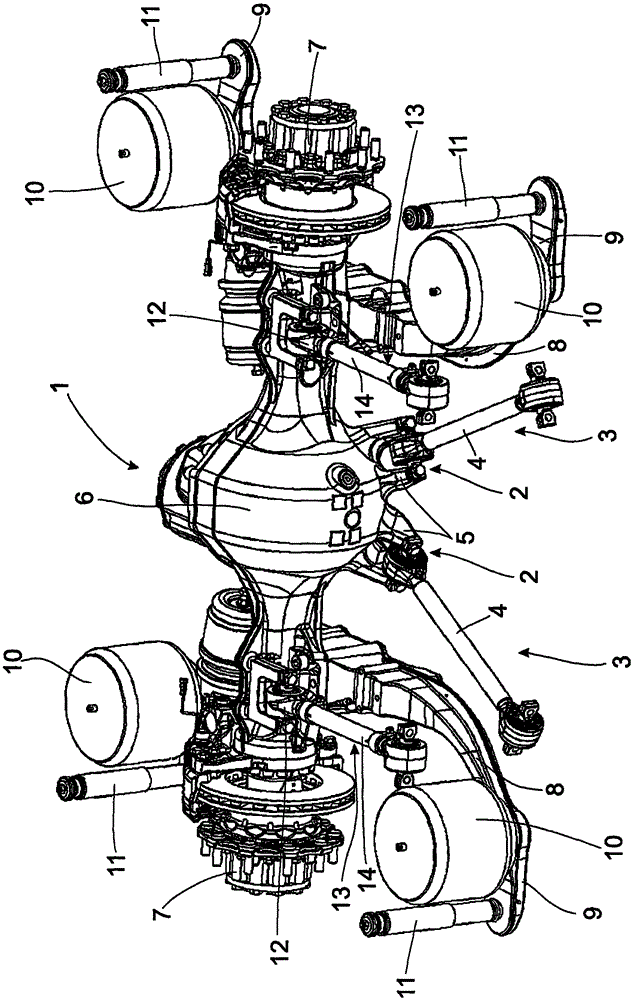

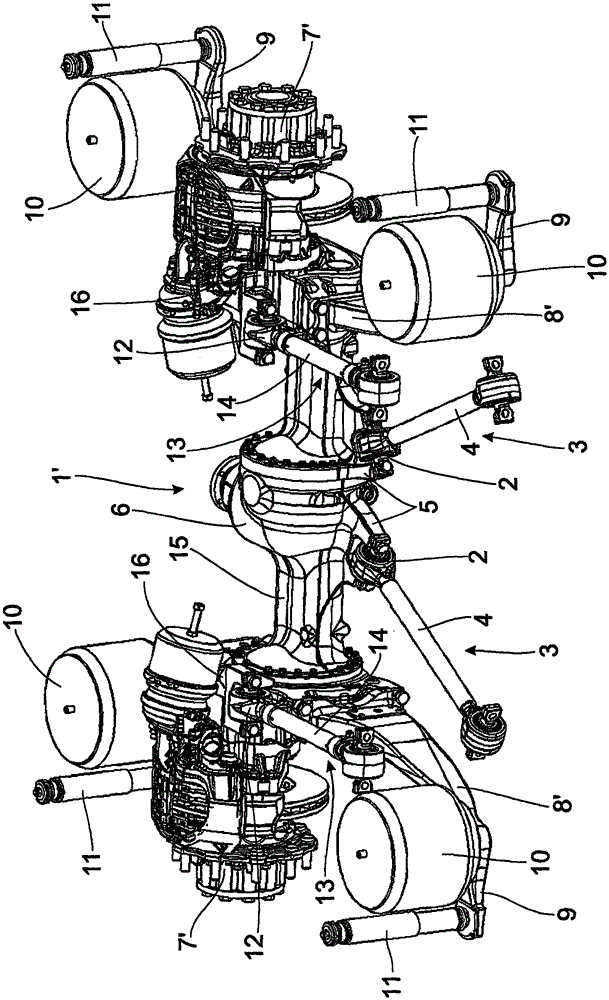

[0022] The illustrated axle suspension of the vehicle generally has an axle housing 1 , 1 ′, 1 ″, 1 ″′ made of metal as a cast part, wherein figure 1 and figure 2 The axle housings 1 and 1' have a transmission housing 6 in the center and are provided for a driven axle. A rotatably mounted wheel drive shaft, not shown, passes through the axle housing 1 , 1 ′, 1 ″, 1 ″′. It goes without saying that, alternatively, the axle housing 1 , 1 ′, 1 ″, 1 ″′ can be formed as a welded structural unit from several parts.

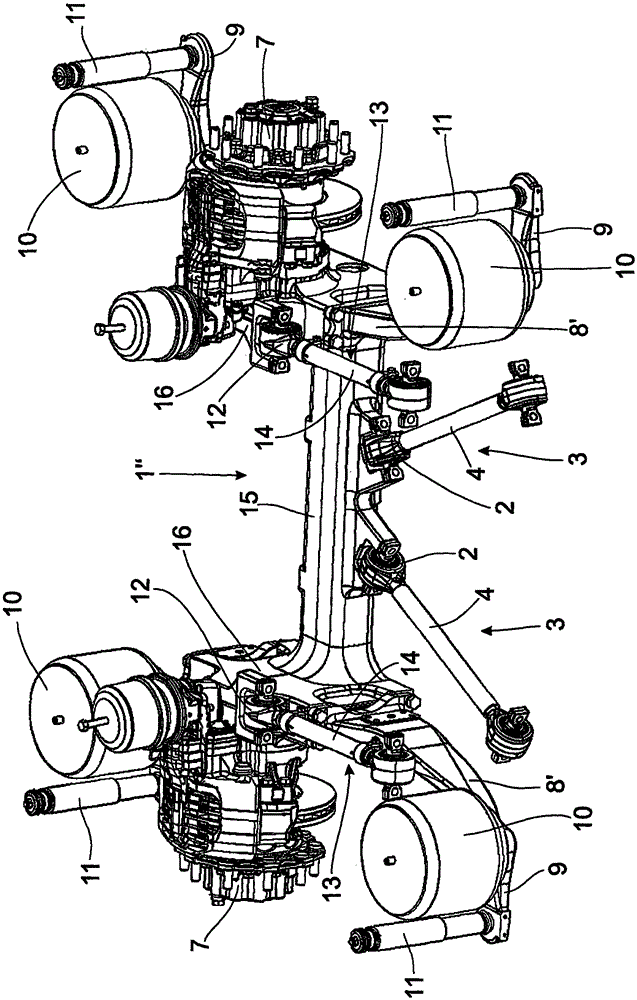

[0023] image 3 and Figure 4 Axle housings 1" and 1"' are provided for non-driven axles and also as figure 2 The portal bridge in.

[0024] In the lower regions of the axle housings 1, 1', 1", and 1"', respectively, two second articulation sites 2 are arranged side by side, at which the triangular cantilever 3 is hinged, and the two stays of the triangular cantilever 4 extends separately from the second articulation point 2 in one plane. The end of the strut 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com