A Flapping Rotor Using Openings to Realize Increased Lift

A flapping rotor and wing membrane technology, applied in the field of flapping rotors, can solve the problems of low energy utilization rate and small average lift of flapping rotors, and achieve the effects of increased energy utilization rate, average lift, and easy-to-obtain materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

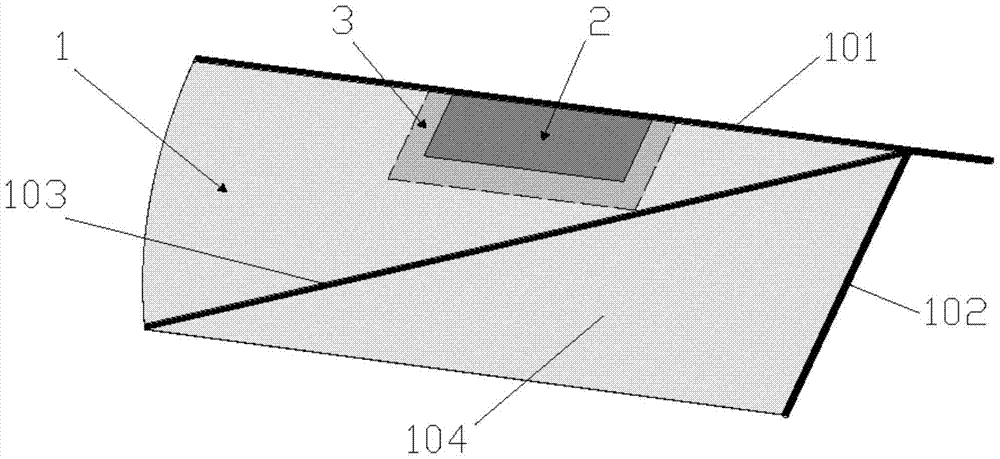

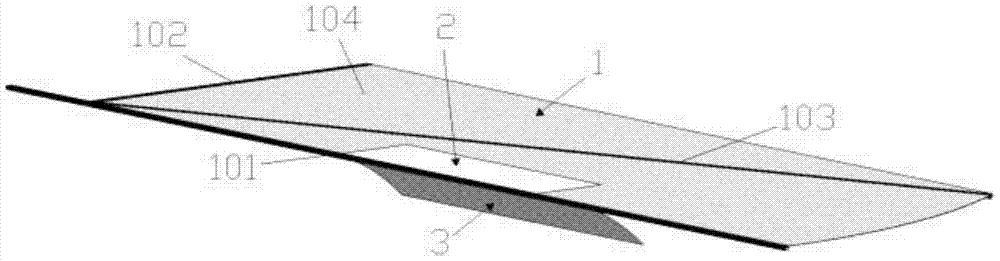

[0026] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

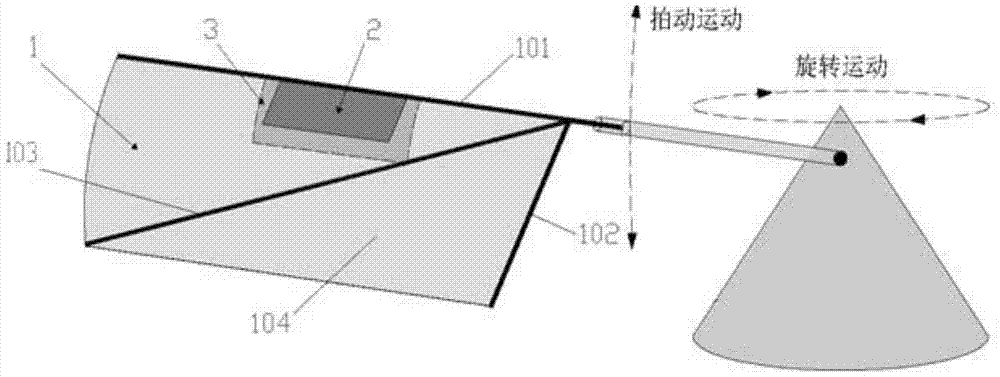

[0027] A fluttering rotor that uses openings to increase lift. The working principle is as follows:

[0028] During the use of the micro flapping rotor, the general angle of attack is fixed between 0° and 30°. When the flapping rotor moves upwards, taking the flapping rotor as the reference frame, the flapping motion produces a downward airflow relative to the flapping rotor. After superimposing with the rotating incoming flow, the effective angle of attack formed by the real incoming flow and the flapping rotor is negative. When the pressure on the upper surface of the wing is greater than that on the lower surface, negative lift will be produced on the conventional flapping rotor. When the flapping rotor moves downward, the effective angle of attack formed by the real incoming flow and the flapping rotor is positive. At this time, the pressure on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com