A flapping-wing aircraft with twisted inner wings

A flapping-wing aircraft and inner wing technology, applied in the field of flapping-wing aircraft, can solve the problem that the wing structure fails to achieve flapping and torsion, achieve smooth flapping and torsion, reduce the weight of the fuselage, and improve the processing and assembly performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

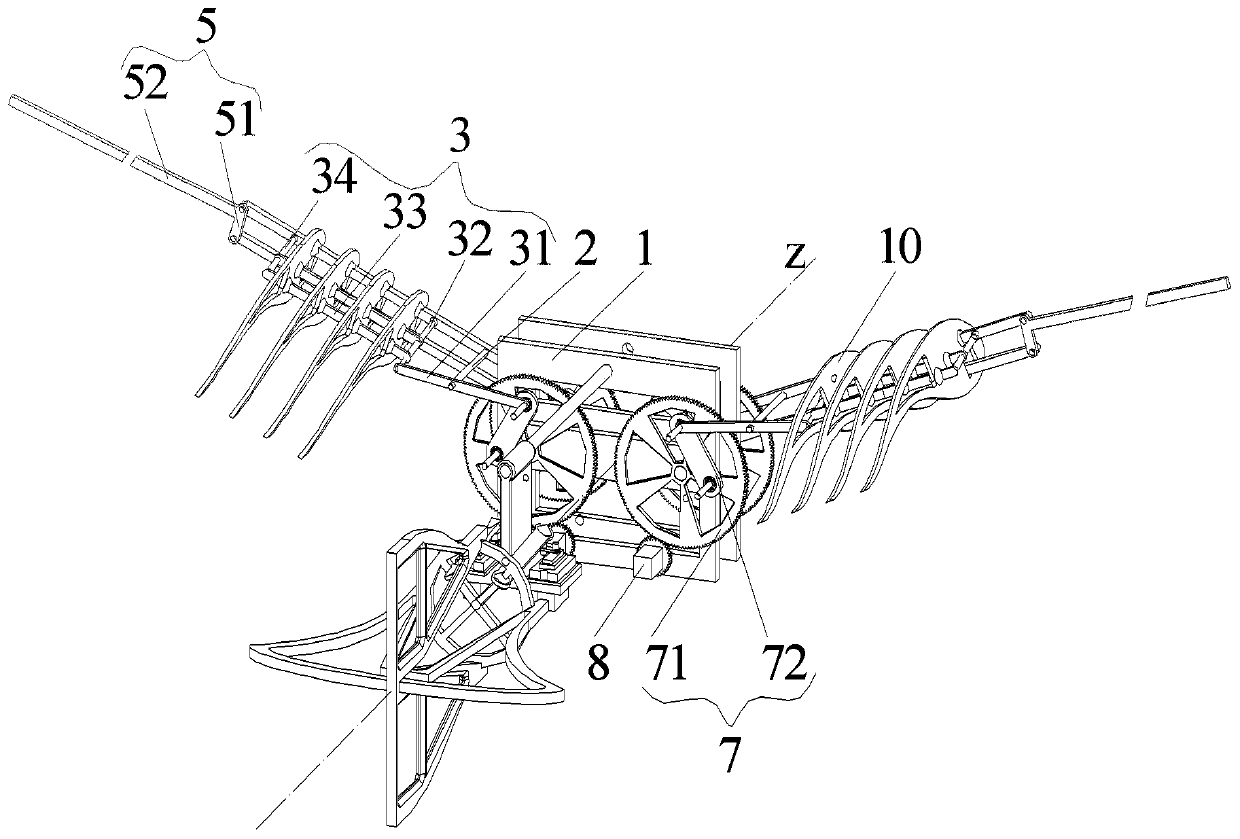

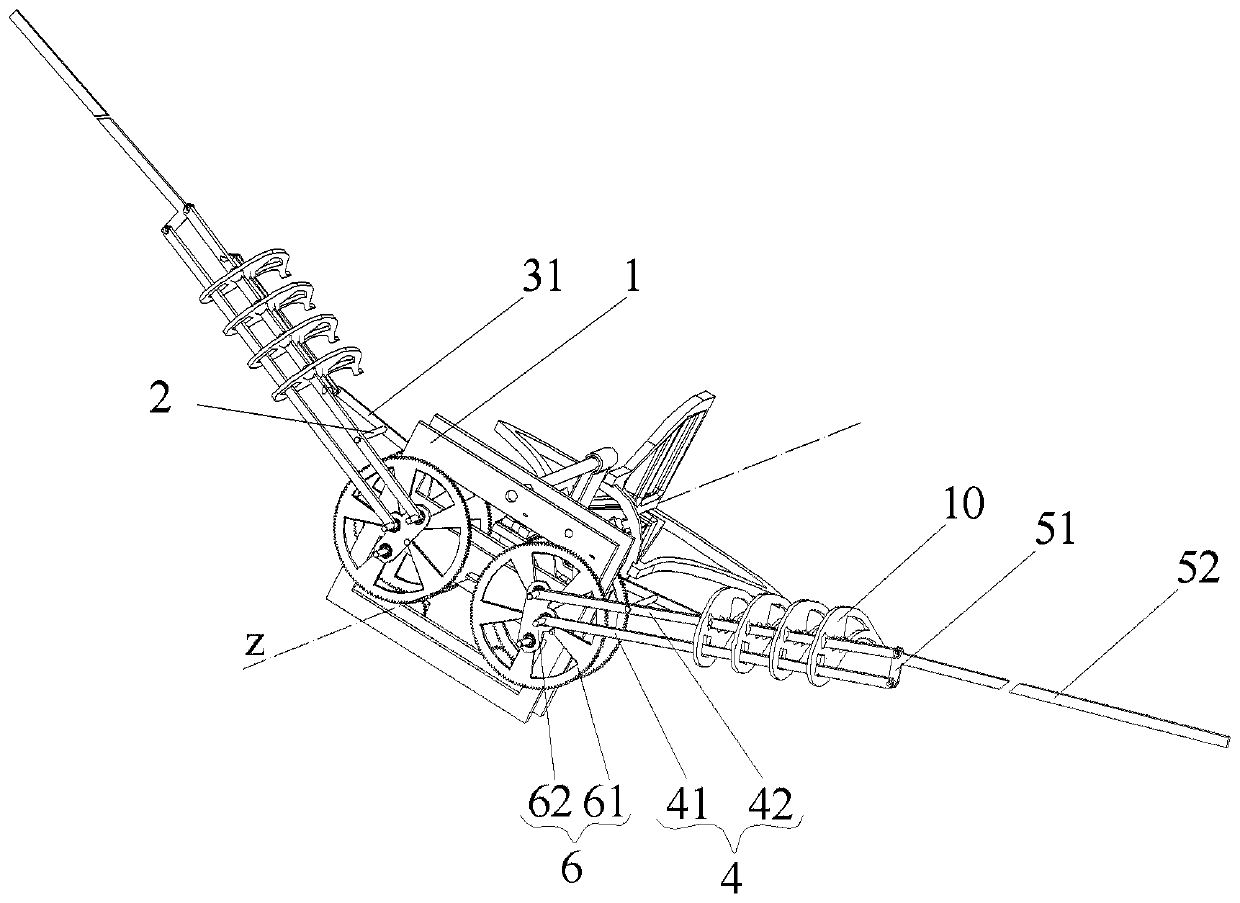

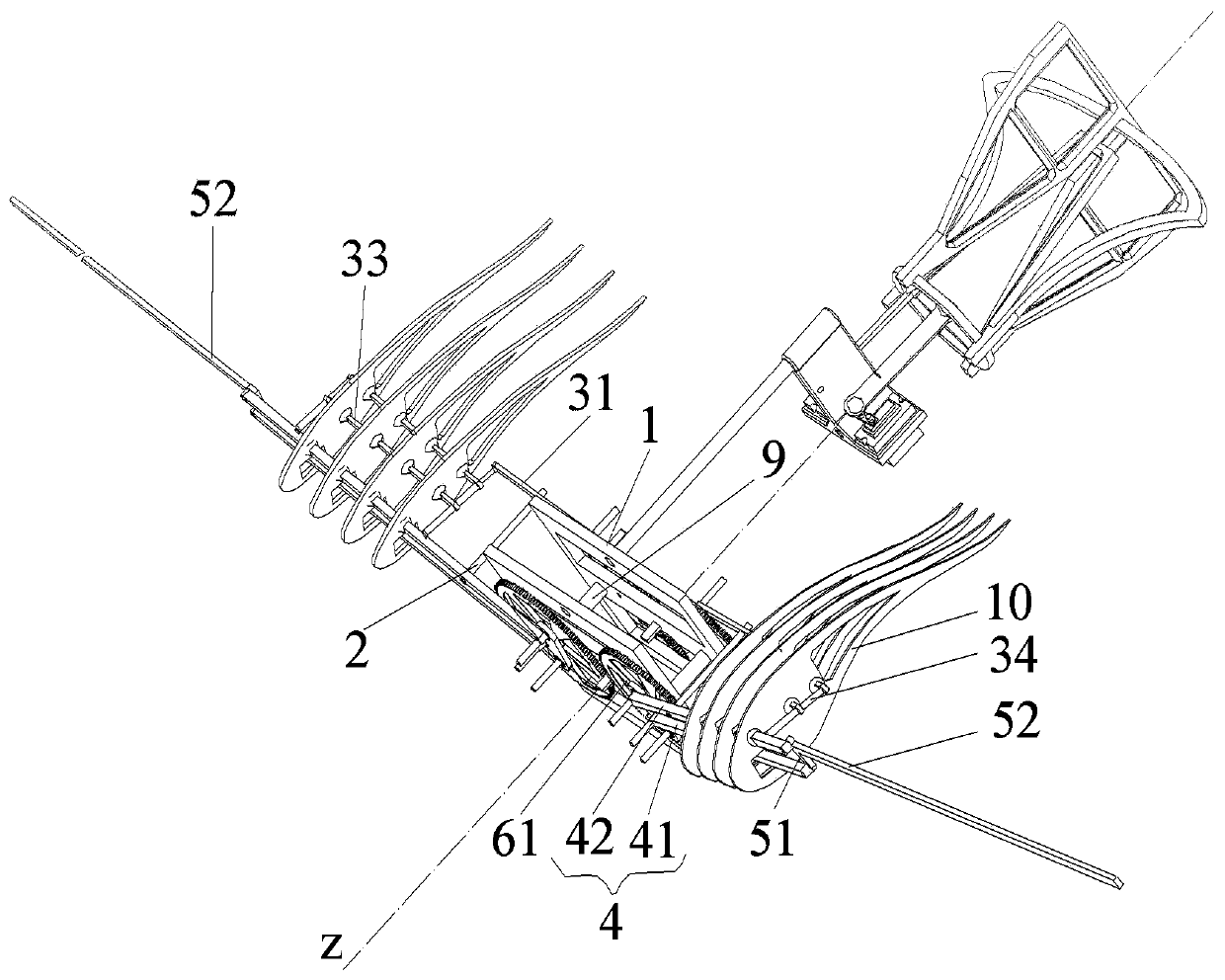

[0062] The invention provides a flapping-wing aircraft with twisted inner wings. A pair of fully symmetrical double crank and double rocker mechanisms are used as the flapping wing mechanism. The motor drives the flapping wing mechanism to flap up and down through the deceleration mechanism to generate the lift required for flight. A set of internal wing mechanisms distributed forward and backward is designed. The front and rear driving structure is the same, and there is a 45° movement phase difference, which generates corresponding lift and thrust, and realizes flapping wing action in accordance with the principle of flapping wing flight.

[0063] 1. Structure introduction:

[0064] In an exemplary embodiment of the present invention, a flapping-wing aircraft with twisted inner wings is provided. Such as Figure 1-3 As shown, the present invention includes: a frame 1, a wing, and a driving device capable of simultaneously realizing flapping and twisting of the wing.

[0065] Each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com