A flapping rotor with an angle of attack control device

A control device and a flapping rotor technology, applied in the field of flapping rotors, can solve the problems of low energy utilization rate, small average lift of flapping rotors, etc., and achieve the effects of improved energy utilization rate, improved average lift, and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

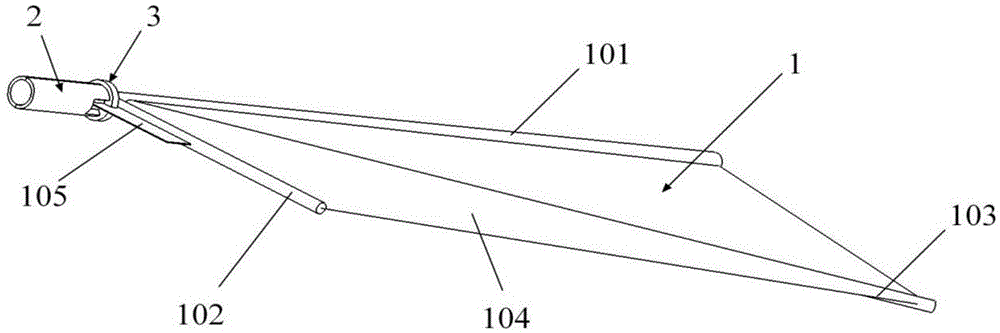

[0033] A flapping rotor with an angle of attack control device includes a flapping rotor 1 , an angle of attack controller 2 and a limiter 3 .

[0034] Flapping rotor 1 such as figure 1 As shown, it includes a main beam 101 , a short beam 102 , an oblique beam 103 , a membrane 104 and a baffle 105 .

[0035] The main beam 101, the short beam 102 and the inclined beam 103 are made of carbon fiber rods, the wing membrane 104 is made of polyethylene film, and the baffle 105 is made of carbon fiber board.

[0036] The main beam 101, the short beam 102, the inclined beam 103 and the baffle 105 are in the same plane, the short beam 102 is perpendicular to the main beam 101, the inclined beam 103 is located between the main beam 101 and the short beam 102, and the included angle with the main beam 101 is 30° to 60°. The root of the short beam 102 and the root of the inclined beam 103 are fixedly connected to the root of the main beam 101 , and the intersection point is located at 1...

Embodiment 2

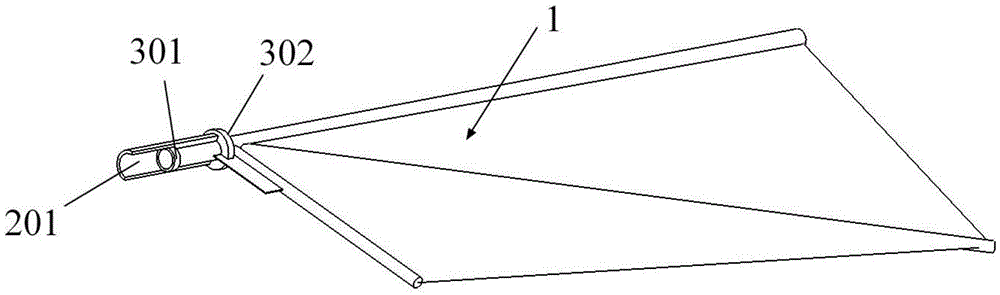

[0052] A flapping rotor with an angle of attack control device includes: a flapping rotor 1 , a deformation piece 4 and a limit beam 106 .

[0053] Such as Figure 4 As shown, the flapping rotor 1 includes: main beam 101 , short beam 102 , inclined beam 103 and wing membrane 104 . The main beam 101, the short beam 102 and the inclined beam 103 are all made of carbon fiber rods, and the wing membrane 104 is made of polyethylene film.

[0054] The main beam 101 is coplanar with the short beam 102 and the inclined beam 103, the short beam 102 is perpendicular to the main beam 101, the inclined beam 103 is between the main beam 101 and the short beam 102, and the angle between the main beam 101 and the main beam 101 is between 30° and 60° between. The wing membrane 104 is glued below the plane formed by the main beam 101 , the short beam 102 and the inclined beam 103 . The short beam 102 and the oblique beam 103 are fixedly connected at the root, the connection point is about 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com