A kind of material sampling device for taking small samples

A technology of small sample size and material, which is applied to conveyor control devices, packaging, conveyor objects, etc., can solve the problems of inability to extract fine weave, unintelligent operation, unreasonable design, etc., avoiding semi-automation and simple operation. Convenience and rational design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

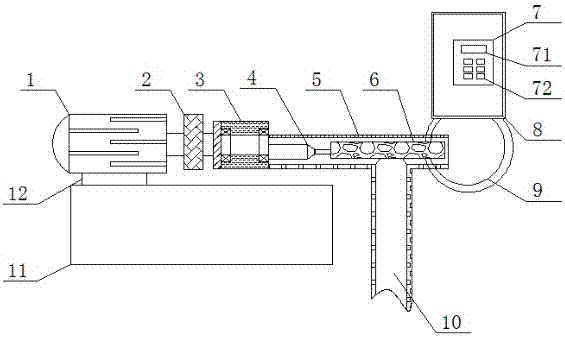

[0014] Examples such as figure 1 Shown, a kind of small sample amount is taken material sampling device, comprises motor 1, coupling 2, push rod 4 and base 11; The top of base 11 is provided with support frame 12, and motor 1 is installed on the top of support frame 12, coupling The device 2 is installed on the right side of the motor 1, and the right side of the coupling 2 is provided with a bearing bracket 3, and the right side of the bearing bracket 3 is provided with a delivery pipeline 5, and the push rod 4 is embedded and installed inside the delivery pipeline 5, And the bearing seat bracket 3 is connected with the conveying pipeline 5 through the push rod 4, the right side of the push rod 4 is provided with the feeding cylinder 6, the conveyer belt 10 is arranged under the feeding cylinder 6, and the screw...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap