An integral profile control process of nitrogen foam in the process of exploiting heavy oil reservoirs

A technology of nitrogen foam and heavy oil reservoirs, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of complex operation of steam flooding nitrogen foam profile control process and the inability to realize overall profile control, etc., to achieve Improve the effect of implementation, prolong the period of validity of blockage adjustment, and improve the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

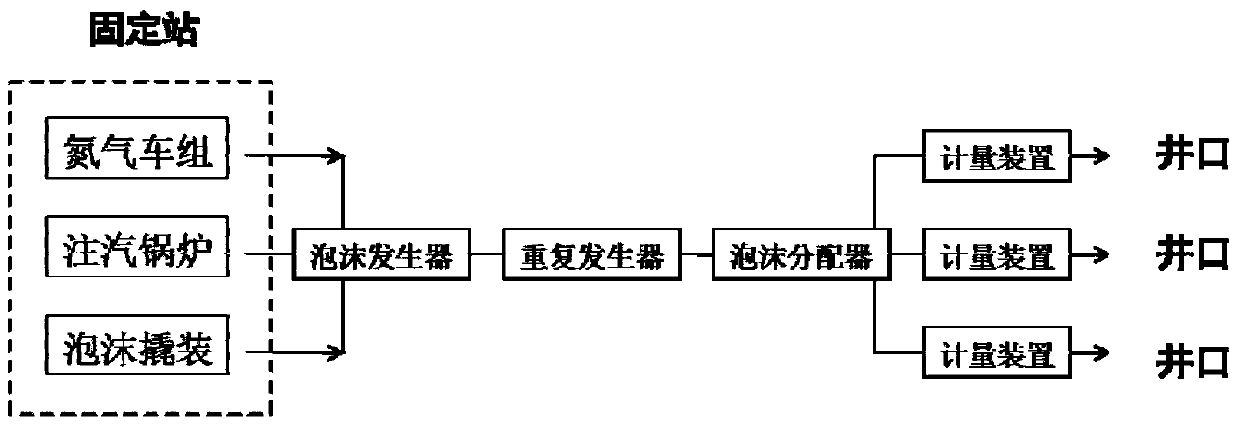

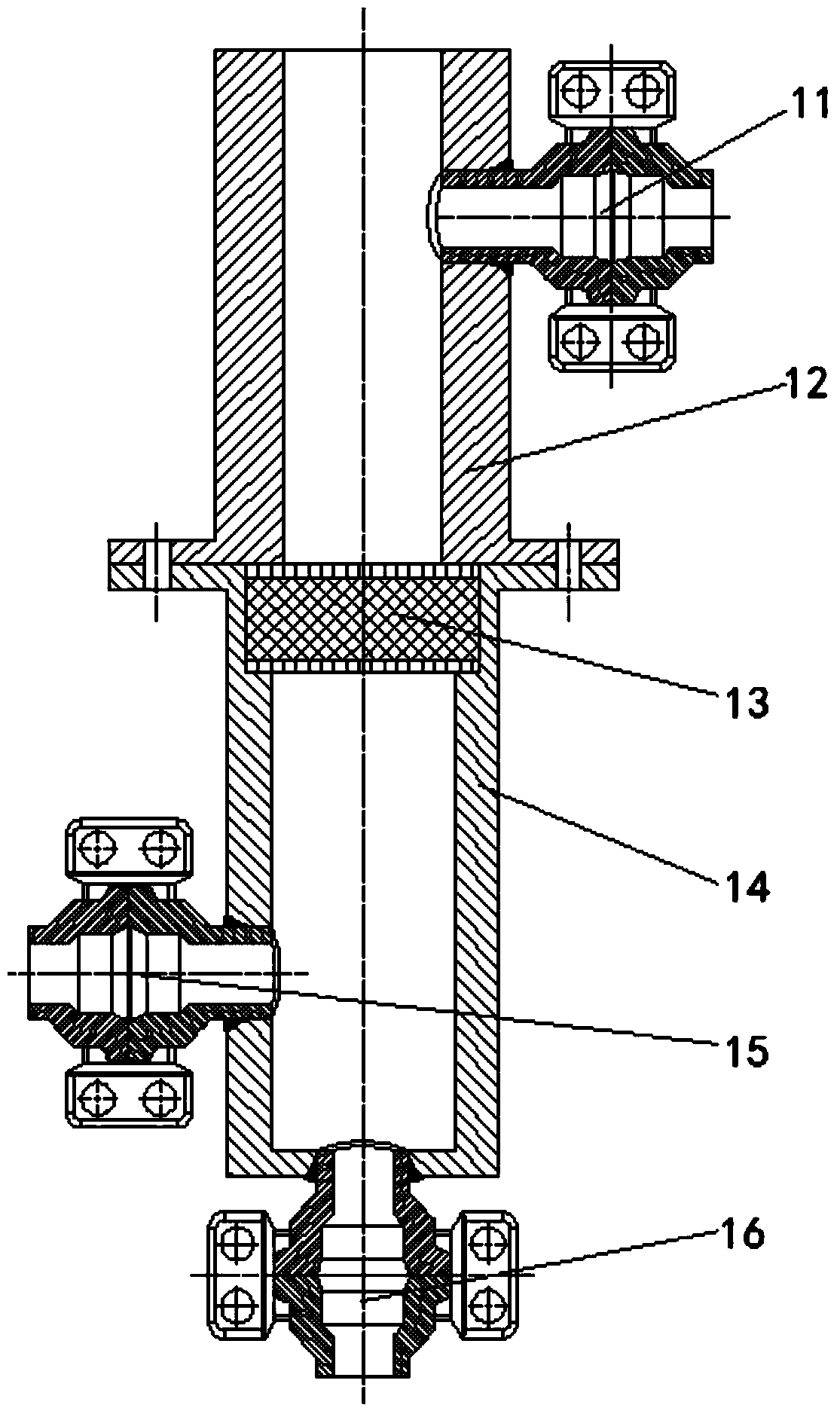

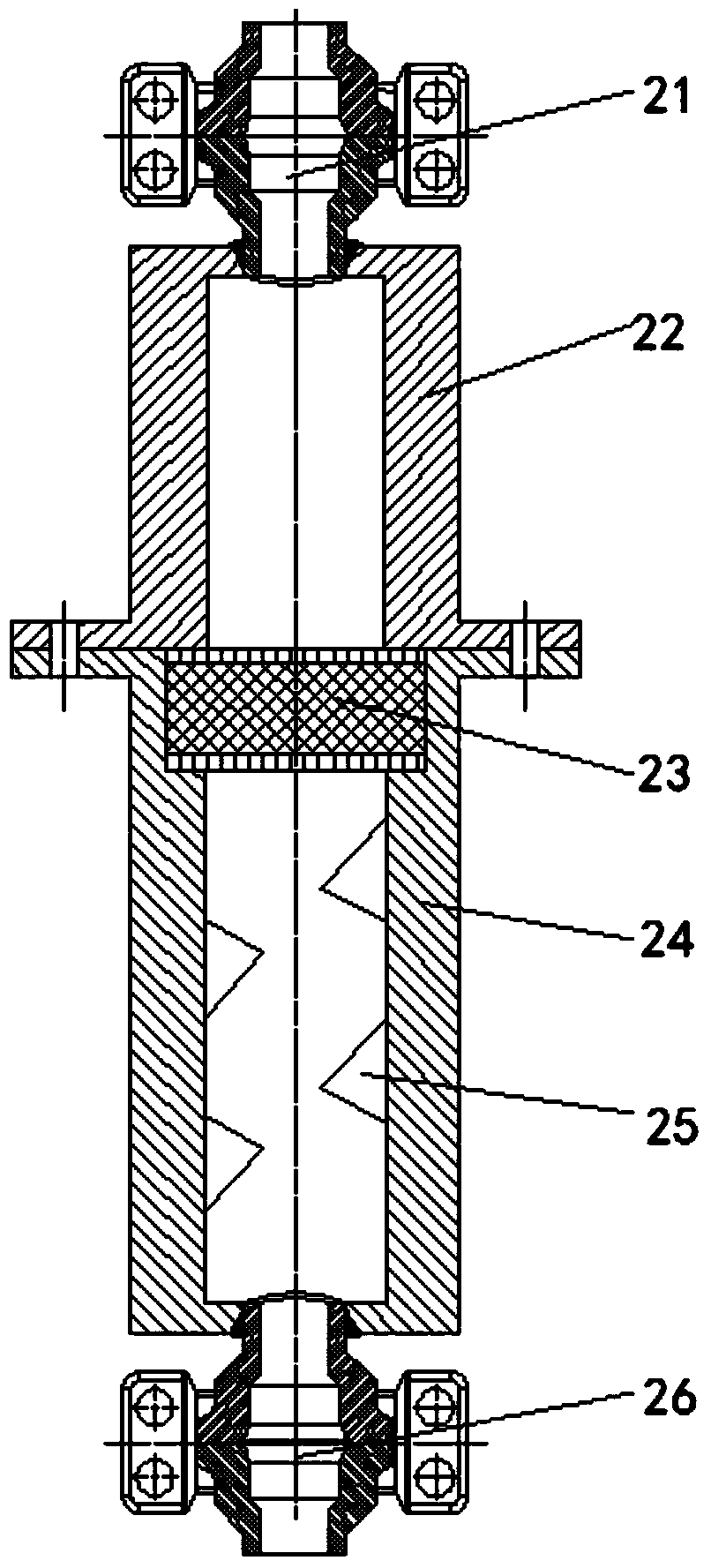

[0026] Such as figure 1 As shown, configure the nitrogen foam profile control process according to the flow chart, and the foam generator, repeat generator, foam distribution device, and foam metering device used in it should be selected and installed according to the corresponding structure diagram. Establish a fixed station to implement unified management. The fixed equipment includes: nitrogen train units, steam boilers and foam agent injection skids, and install foam generators, repeat generators, foam distribution devices, and foam metering devices in the nitrogen foam pipe network to realize nitrogen foam. Evenly distributed to the steam flooding injection well group. The method of using the device includes: s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com