Foaming agent injection skid-mounted device

A foam agent and injection system technology, applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of increased water content in the produced fluid, steam gas channeling, and poor effect, so as to improve the oil-gas ratio , reduce interfacial tension, and reduce the cost of plugging and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

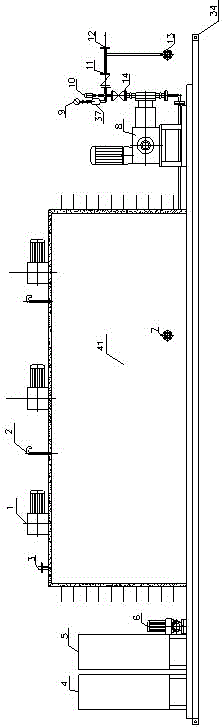

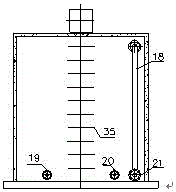

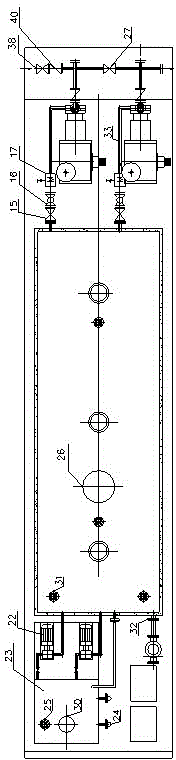

[0028] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

[0029] Such as Figure 1-6 As shown, configure the nitrogen bubble injection skid according to the effect diagram, and the chemical tank and heating system, injection pump and distribution valve system, power distribution and monitoring system accessories inside the skid should be selected and installed according to the corresponding structure diagram. The method of using the device includes: step 1, injecting the external foam agent into the skid; step 2, injecting nitrogen into the skid by the nitrogen truck; Pressure, foam agent flow, monitor distribution valve group high-pressure nitrogen inlet pressure, nitrogen flow, monitor foam tank temperature, liquid level, and finally output high-pressure nitrogen foam.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com