Test method for isotope labeling of water-producing parts of high water-cut horizontal wells

A technology of isotope labeling and testing method, which is applied in the field of isotope labeling testing of water outlet parts of high-water-cut horizontal wells, can solve the problems of difficult implementation and high cost, and achieve the effects of simplifying construction steps, high measurement accuracy, and reducing platform occupation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

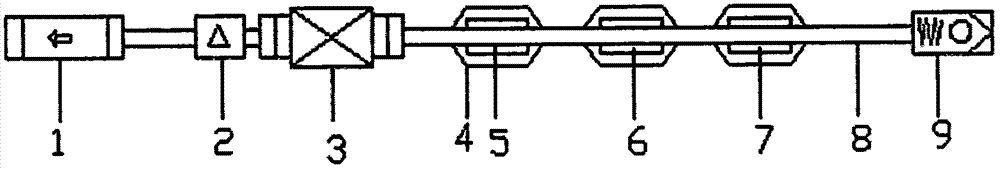

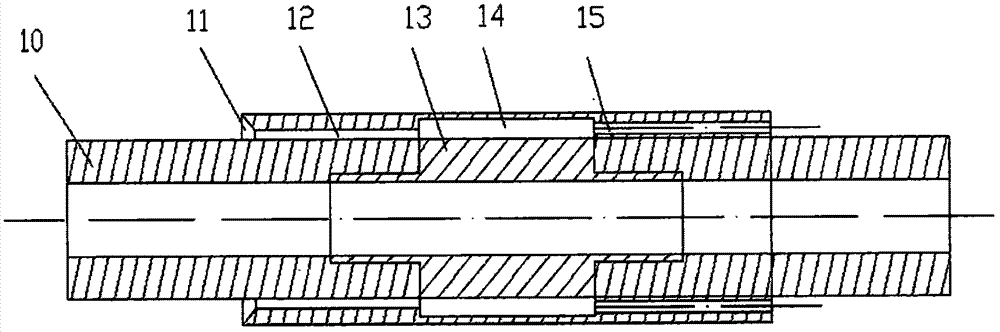

[0033] figure 1 It is a schematic diagram of the connection of downhole devices in the isotope labeling test method of the water outlet part of the high water-cut horizontal well of the present invention, figure 2 It is a structural schematic diagram of the isotope releasing device in the present invention. exist figure 1 , figure 2 In the test example, the test process of the present invention is described. However, those skilled in the art should know that the present invention is not limited to the specific embodiments listed, as long as it conforms to the spirit of the present invention, it should be included in the protection scope of the present invention.

[0034] The testing process of the present invention includes three processes: testing device assembly, oil pipe transmission and running, and production testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com