Apparatus used for nylon casting centrifuge to solve dynamic support

A nylon casting and centrifuge technology is applied in the field of devices used for nylon casting centrifuges to solve dynamic support, which can solve the problems of imperfect casting of parts, poor casting effect, unsafe dynamic casting, etc., so as to reduce potential safety hazards and achieve casting effect. good, perfect effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

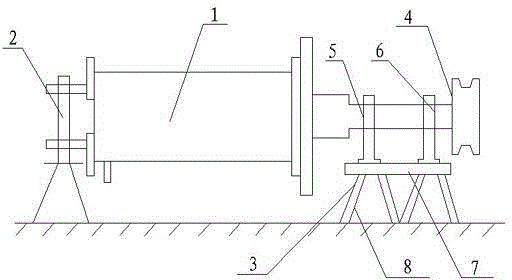

[0011] Below in conjunction with accompanying drawing, this design is described in detail.

[0012] see figure 1 : a device for dynamic support of a nylon casting centrifuge, comprising a centrifuge 1, the left and right sides of the centrifuge 1 are respectively provided with a left bracket 2 and a right bracket 3, and the left bracket 2 is connected with the screw by a screw The left end face of the centrifuge 1 is connected, and the right bracket 3 supports the feed inlet of the centrifuge 1 through the support claw one 5 and the support claw two 6, and the feed inlet of the centrifuge 1 is connected with a hollow bearing 4, Right support 3 is arranged between hollow bearing and right support 3, and described right support 3 comprises supporting leg 8, crossbeam 7, support claw one 5 and support claw two 6, and crossbeam 7 is provided with axial groove, and described The supporting claw one 5 and the supporting claw two 6 are arranged in the groove of the beam 7, and are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com