Crane tackle with plunger spring automatically conducting clamping during stress and five wheels rapidly hanging-in or quitting

A technology of hoisting tackle and hoisting trolley seat, which is applied in the field of hoisting trolleys, which can solve problems such as unsafety, accidents, and time delays, and achieve the effect of easy installation and strong interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

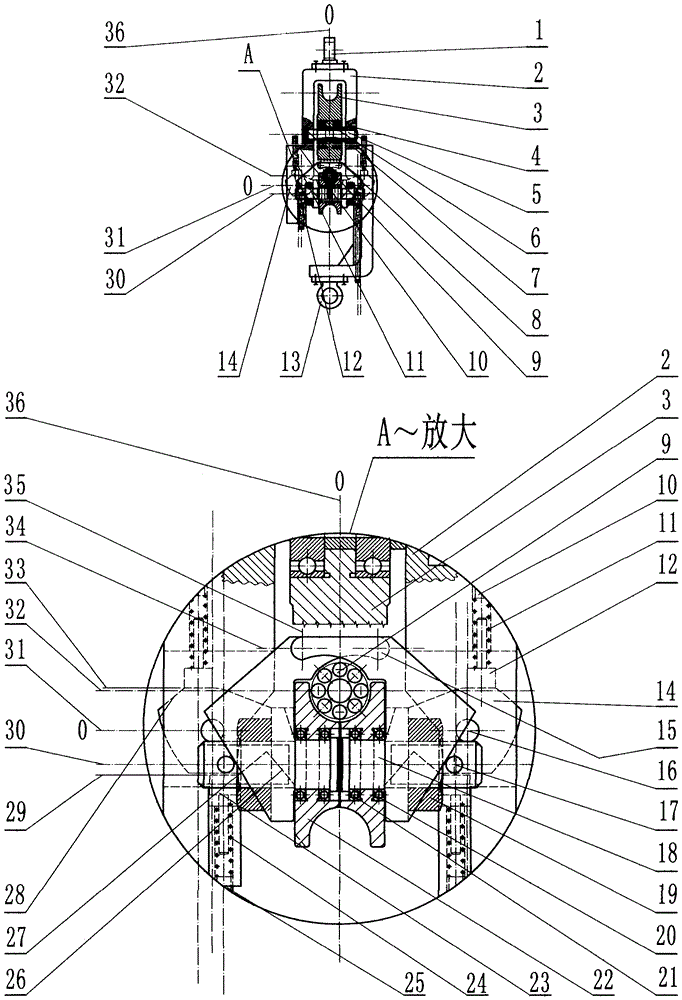

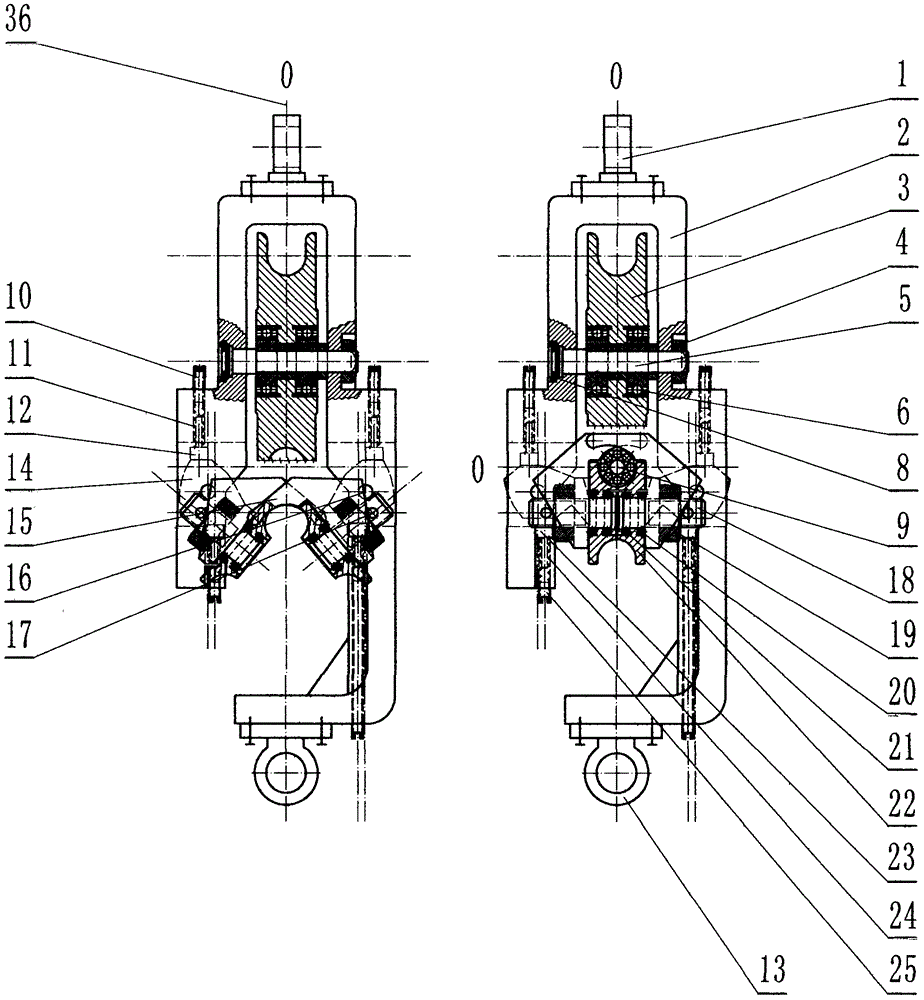

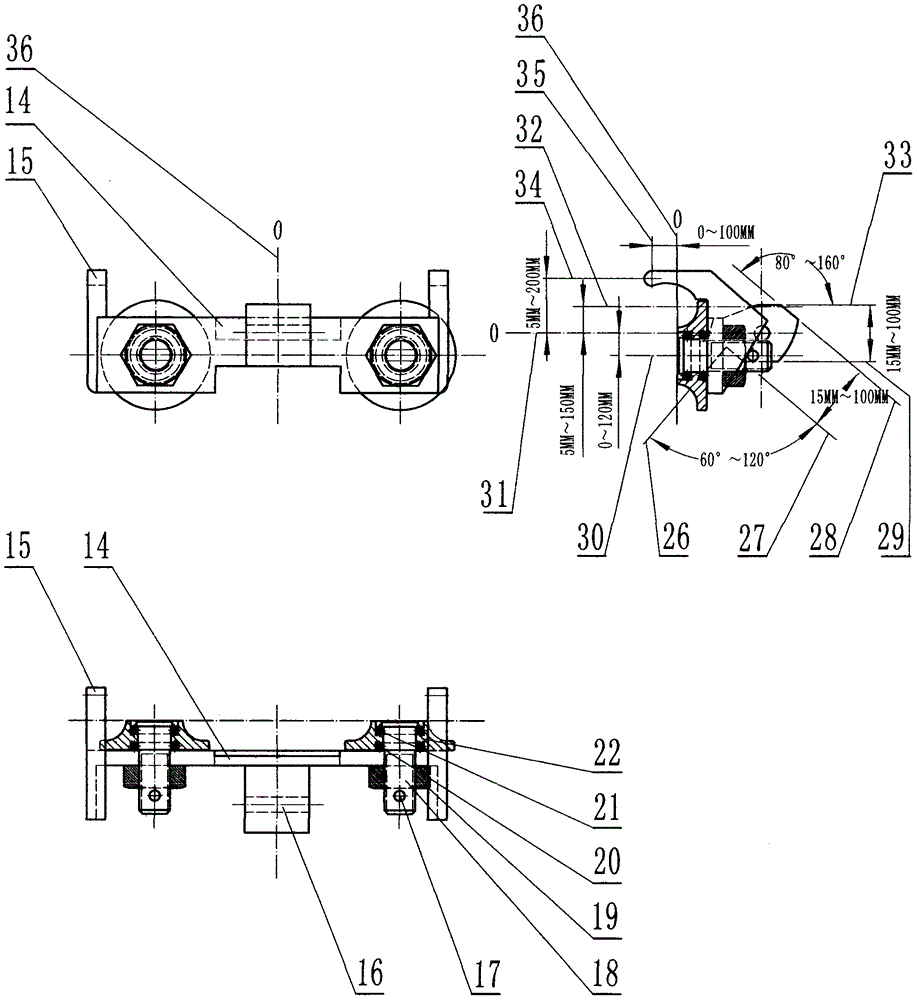

[0012] The technical solution adopted by the present invention is: it is composed of a suspension block assembly, a suspension pulley assembly, and a clamping seat assembly:

[0013] see figure 1 . figure 2 .The shape of the hoist block assembly is like a 9 or designed as a U-shape rotated 180°. The hoist block assembly consists of the upper replaceable suspension (1), the hoist block (2), and the upper adjustment tightening screw ( 10), upper column type spring (11), upper positioning column (12), lower replaceable suspension (13), lower positioning column (23), lower column type spring (24), lower adjusting tightening screw (25) composition. The upper replaceable suspension (1) is fastened with screws or formed on the upper part of the suspension block (2) by casting or machining; The columns (12) are assembled in the two sides of the upper part of the suspension block (2) in order, and the upper positioning column (12) can elastically slide up and down in the suspension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com