The Method of Lengthening and Closing the Pile Legs of Jack-up Drilling Platform

A drilling platform pile leg and drilling platform technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of high-altitude operations, long operation time, high positioning requirements, etc., and achieve high safety, low cost, and welding environment Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

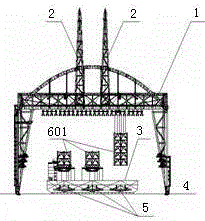

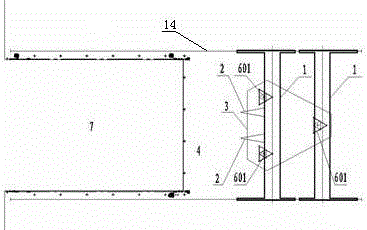

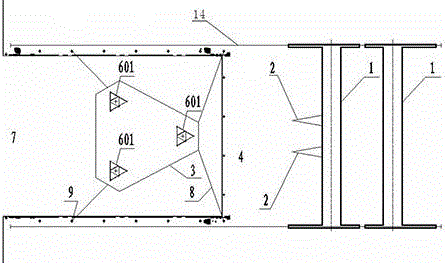

[0044] After the jack-up drilling platform 3 is built on the land site 4 and the spud cans 5 are positioned, the spud legs 6 of the jack-up drilling platform start to be lengthened and closed. The method for lengthening and closing up the pile legs 6 of the jack-up drilling platform of the present invention comprises the following steps:

[0045] 1) if figure 1 As shown, a gantry crane 1 (two gantry cranes 1 are provided in this embodiment) is installed on the dock or harbor basin 7, and installed on the gantry crane 1 (near the dock or harbor basin 7 side) 2 sets of pick-up cranes arranged at intervals, the net distance between the two pick-up cranes 2 is greater than the section size of the pile leg 6 (to prevent the whole pile leg 603 from colliding with the pick-up crane 2 in the lifting project).

[0046] Two pick-up cranes 2 are installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com