Horizontal tube falling film evaporation high-salt wastewater deep concentration device

A technology of falling film evaporation and high-salt wastewater, applied in water/sewage treatment, heating water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of occupying a large three-dimensional space, large initial investment in equipment, and energy consumption and large investment to achieve the effect of reducing equipment power consumption, reducing construction costs, and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

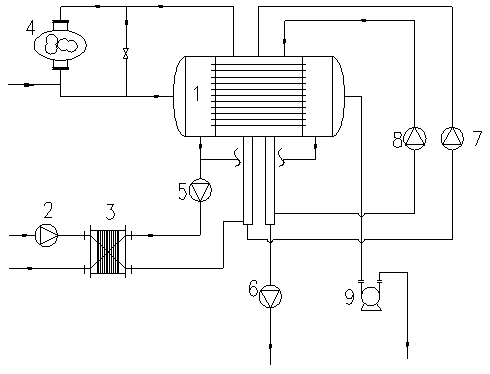

[0022] In order to make the technical solution and advantages of the present invention clearer, this embodiment combines the condensate heat recovery device and the steam recirculation compressor to achieve high brine concentration and recovery of high-quality brine. Compared with the traditional evaporation and concentration equipment, the height of the system device is reduced, the operation and maintenance are convenient, the investment cost is reduced by more than 50%, the energy consumption is reduced by more than 60%, and the system operation is controllable and more stable.

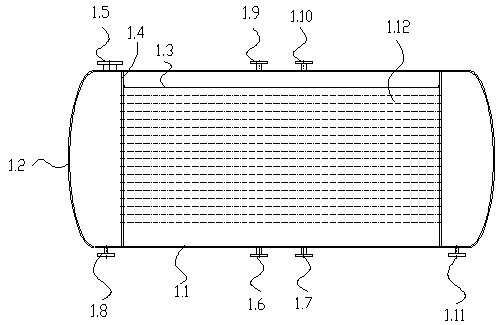

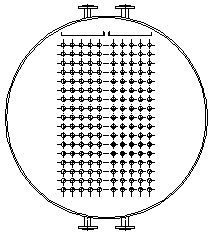

[0023] The main components of the high-salt wastewater in the embodiment are sodium chloride, sodium sulfate, etc., and saturated or superheated steam is used as the heat source. The present invention will be described in further detail below in conjunction with the accompanying drawings. The high-salt wastewater deep concentration device includes a horizontal tube type falling film evaporation con...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap