Hole opening universal quick-assembling fence for hydropower station

A technology for hydropower stations and fences. It is applied in the directions of hydropower stations, fences, and hydropower generation. It can solve the problems of time-consuming, labor-intensive, long handling, and difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

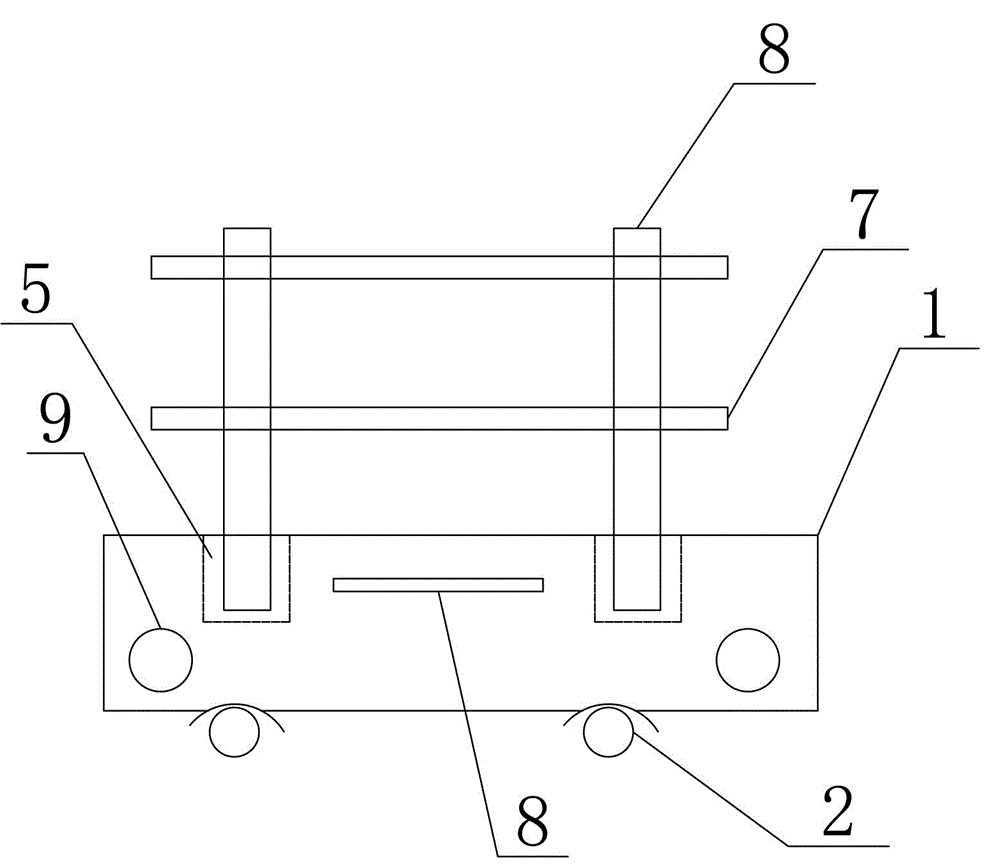

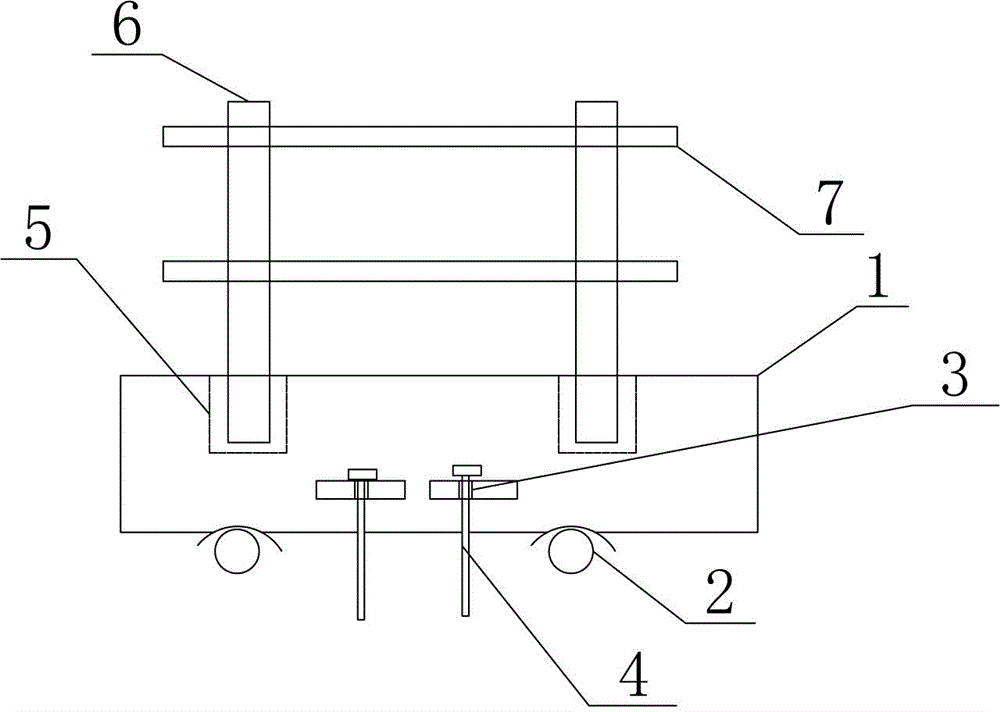

[0017] Such as figure 1 Among them, a universal quick-installation fence for a hydropower station includes a mobile base 1, a sliding wheel 2 is provided on the mobile base 1, and a railing insertion hole 5 is provided on the upper surface of the mobile base 1, and a railing column 6 can be inserted into the railing insertion hole. 5, adjacent railing posts 6 are connected by cross bars 7, such as image 3 A fixed plate is provided on the rear side wall of the mobile base 1, the fixed hole 3 is located on the fixed plate, and one end of the fixed rod 4 can pass through the fixed hole 3, as image 3 Among them, an LED light 8 and a pressure sensor 9 are arranged on the front side wall of the mobile base 1, such as image 3 Among them, the pressure sensor 9 is electrically connected with the alarm device 10;

[0018] When multiple mobile bases 1 are spliced according to the shape of the hole 11 , adjacent mobile bases 1 are connected by connectors (fasteners) or by binding, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com