Supporting roller type test device for dynamically monitoring bending angle

A technology of bending angle and dynamic monitoring, which is applied in the direction of measuring device, using stable bending force to test material strength, angle/taper measurement, etc., to achieve the effect of high dynamic measurement accuracy, real-time monitoring and measurement, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

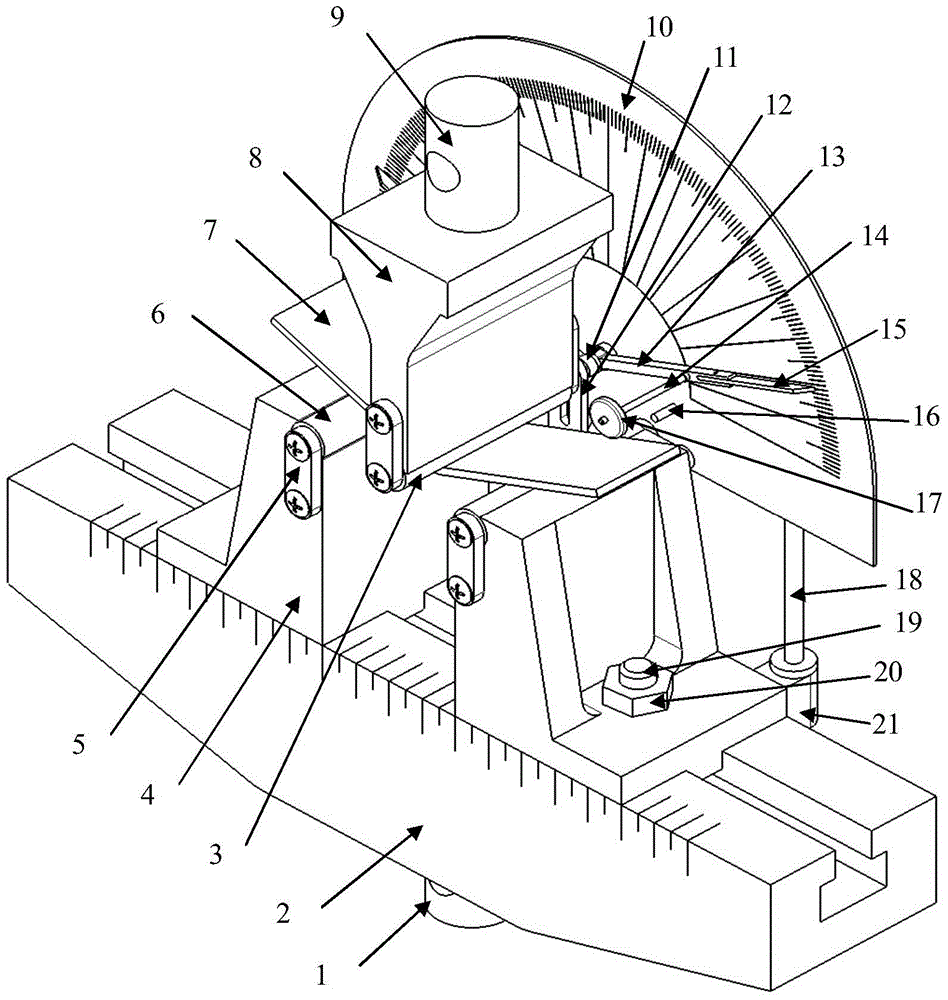

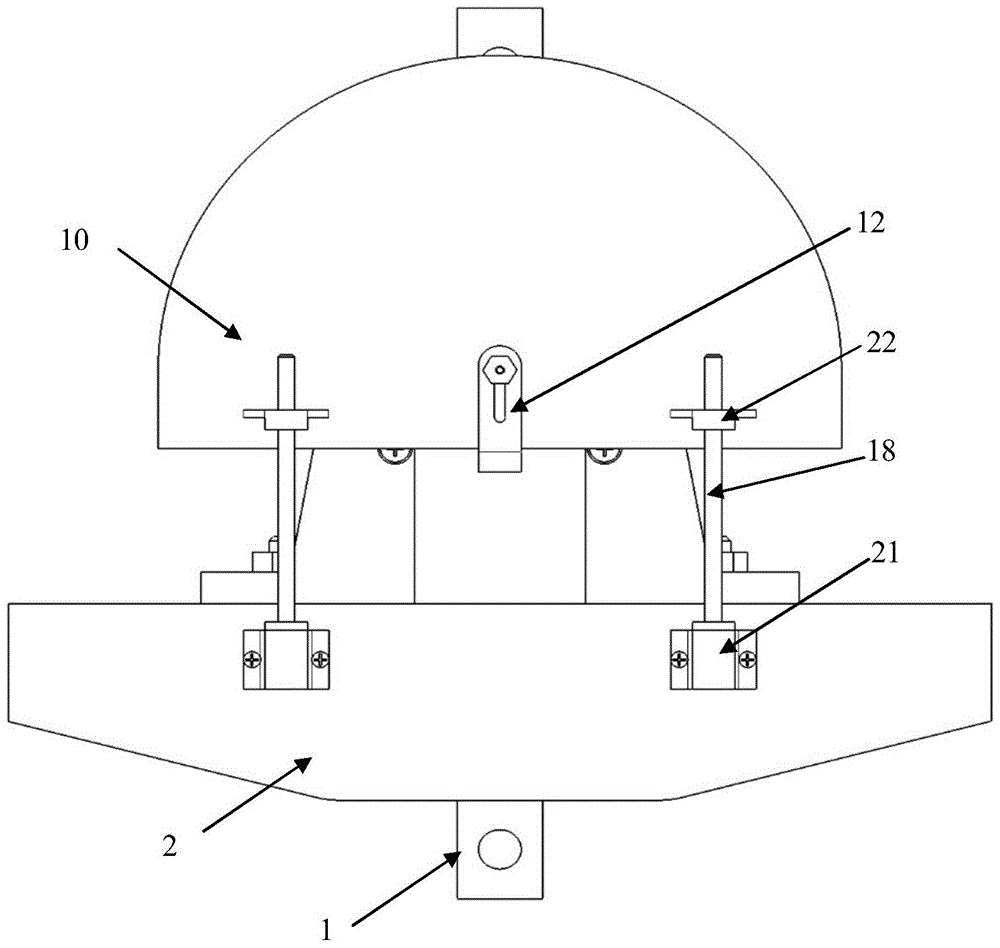

[0017] Such as figure 1 As shown, the supporting roller test device for dynamically monitoring the bending angle disclosed in the present invention is composed of a bending device part and an angle measuring device part. The supporting roller bending test device completes the support and test force application required by the sample in the bending test. The supporting roller bending device mainly includes a lower connecting rod 1, a base 2, a central axis of the bending indenter 3, a support 4, a fixed block 5, a supporting shaft 6, a bending indenter 8 and an upper connecting rod 9, wherein the fixed connection is The lower connecting rod 1 on the bottom plane of the base 2 and the connecting rod 9 fixedly connected to the upper plane of the bending indenter 8 are both smooth-surfaced round rods with a pin hole. Its main function is to realize the connection with the testing machine through the pin. The test bench is connected with the beam to realize that the force value and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com