A method for measuring the coplanarity of solder balls in BGA packaged chips

A technology of coplanarity and chip mounting, applied in the field of measurement, can solve the problems in the field of measurement of coplanarity of solder balls that are not applied, and achieve the effects of high dynamic measurement accuracy, easy follow-up development, and good anti-interference performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

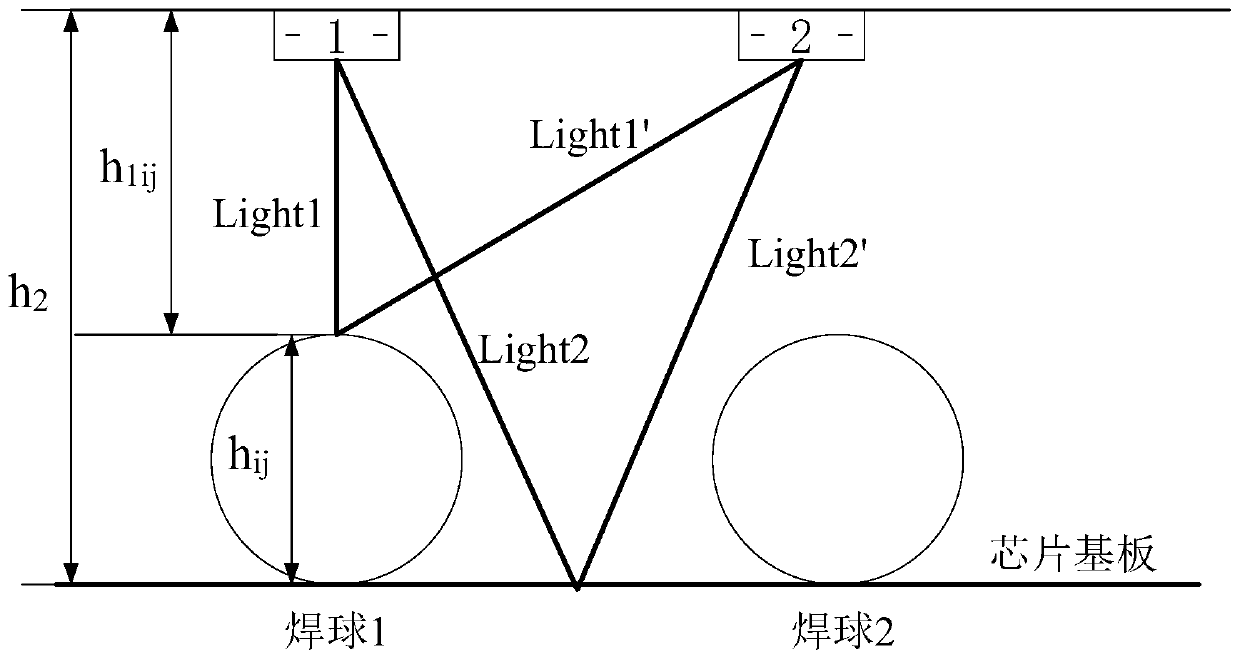

[0025] The invention provides a method for measuring the coplanarity of solder balls of BGA packaged chips. In the method, a gamma photon source 1 equipped with a collimator is used to irradiate a BGA packaged chip in a safe environment, and the gamma photon interacts with the chip and is reflected to a receiving processor 2 . The scintillator in the receiving processor 2 receives the photons backscattered by the chip and multiplies them through the photomultiplier tube to obtain the photon counting frequency by the processing circuit. After simulation, the height from the top surface of the solder ball to the receiving processor is obtained, and then the height of the solder ball is obtained. .

[0026] The method for measuring the copla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com