Two-dimensional position optical measurement system based on multi-linear-array CCD parallel splicing

An optical measurement system and two-dimensional position technology, applied in the field of optical measurement, can solve the problem of expensive optical system and achieve the effect of ensuring measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

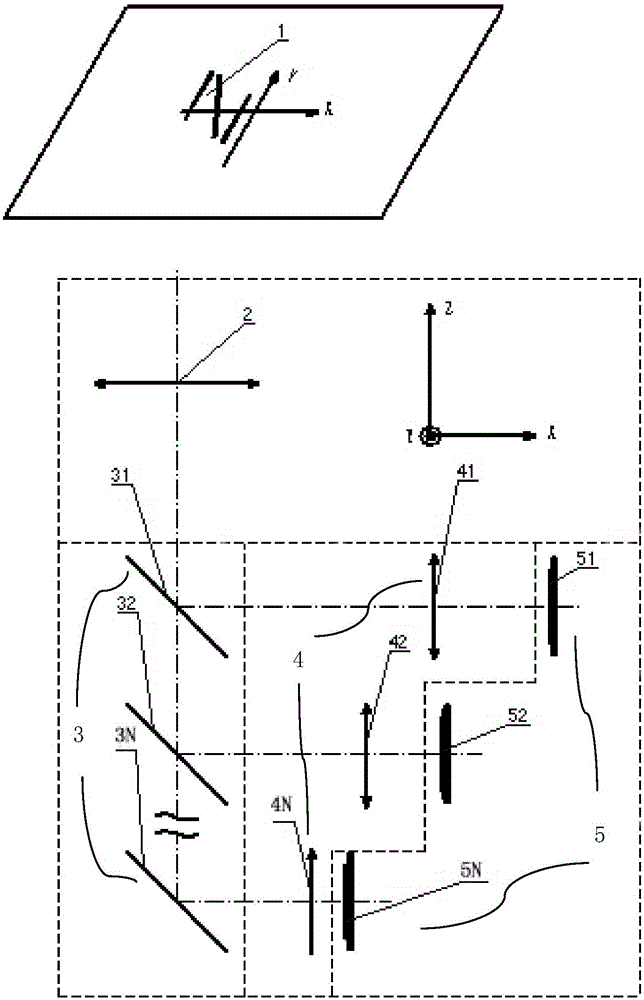

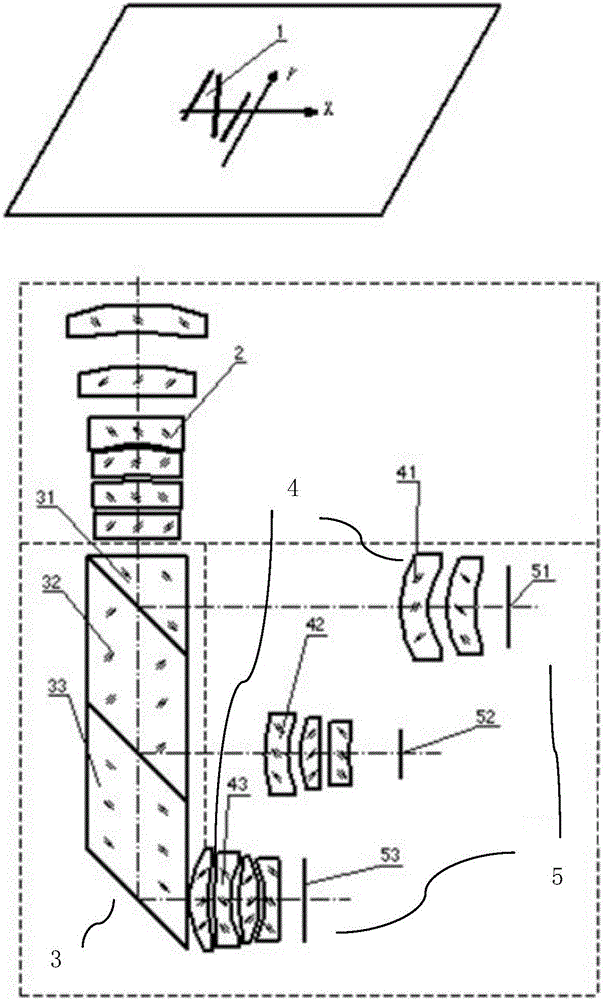

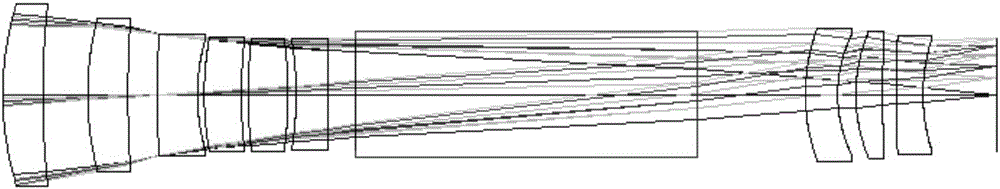

[0027] Such as figure 1 As shown, the two-dimensional position optical measurement system based on multi-linear array CCD parallel splicing provided by the present invention includes a light source cooperative target 1, a common objective lens 2, a beam splitter group 3, a field lens group 4 and a linear CCD group 5.

[0028] The common objective lens 2 is used to collect light beams of various fields of view, the beam splitter group 3 is used to split the light beams, and the field lens group 4 is used to correct the optical path difference of the beams of different fields of view after splitting.

[0029] The light source cooperation target 1 is composed of laser or LED light source or other lighting sources to illuminate the reticle through the uniform light system. In order to reduce the loss of light energy in the measurement process, a wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com